Magnesium calcium RH varnished tube hot spray repair material for smelting silicon steel and formulating method thereof

A gunning material, magnesia-calcium technology, applied in the field of refractory materials, can solve the problems of affecting the resistance to molten steel circulation erosion, affecting the normal operation of the RH furnace, and threatening the life of magnesia-chrome bricks, so as to improve the corrosion resistance and molten steel erosion resistance , excellent erosion, the effect of reducing the amount of liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

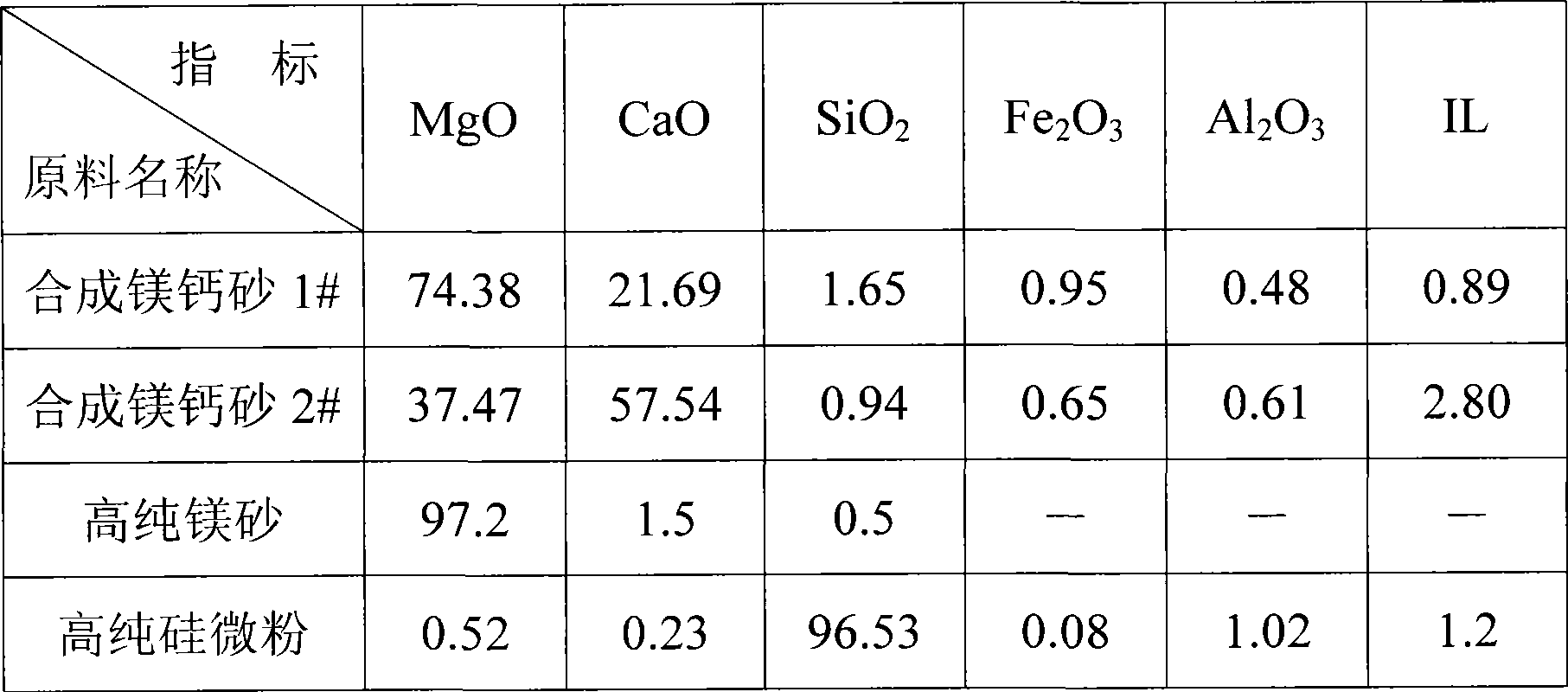

[0033] 1. The purity of selected main raw materials is as follows: (mass percentage content)

[0034]

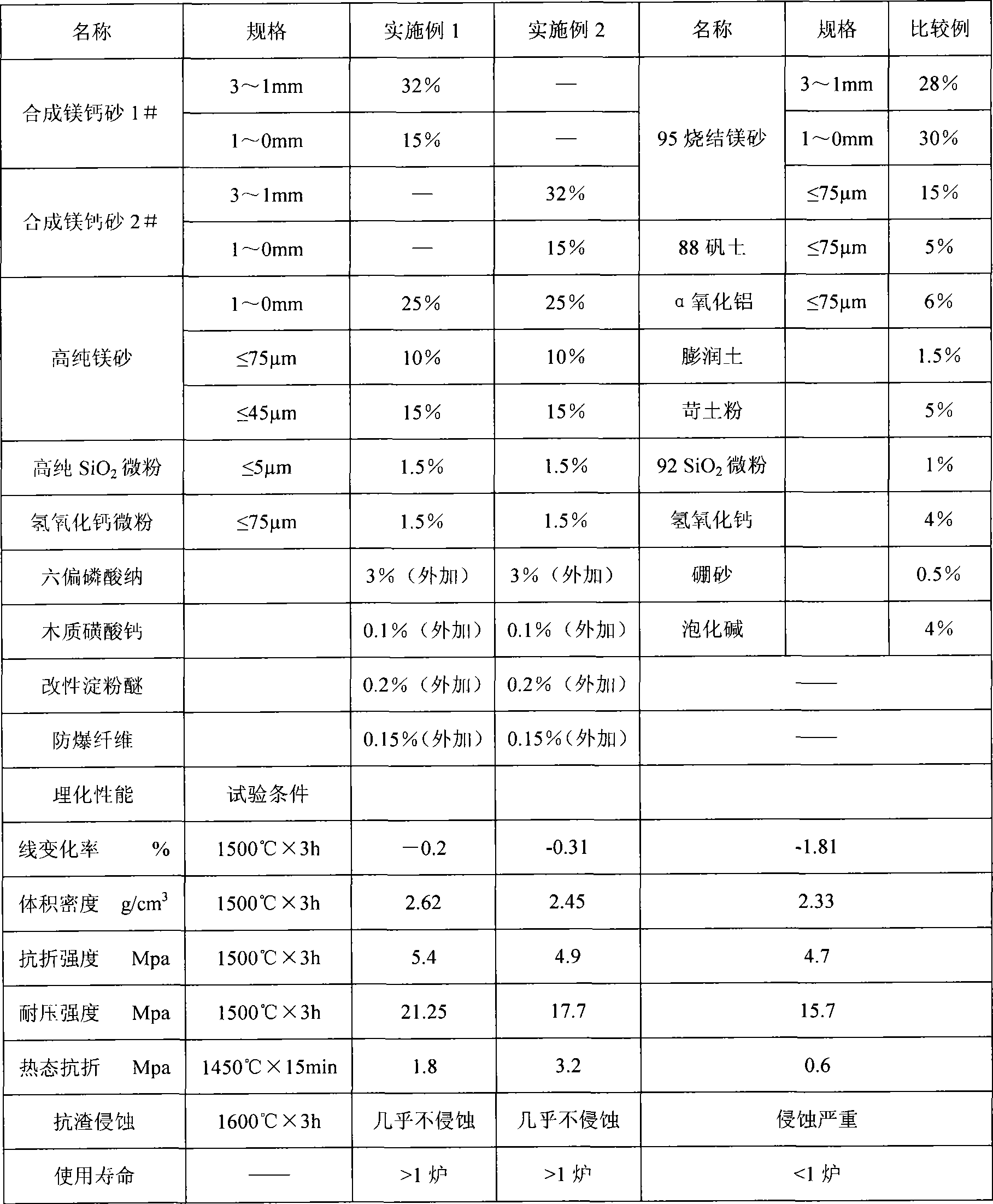

[0035] 2, the composition of embodiment and comparative example and each performance index thereof.

[0036]

[0037] It can be concluded from the above examples that the magnesium-calcium material of the present invention is better than the existing RH dip tube thermal gunning material in terms of corrosion resistance to high alkali slag, thermal strength and service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com