Method for curing soil by using carbonate mineralized bacterium

A technology of mineralizing bacteria and carbonate, applied in the field of solidifying soil with carbonate mineralizing bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

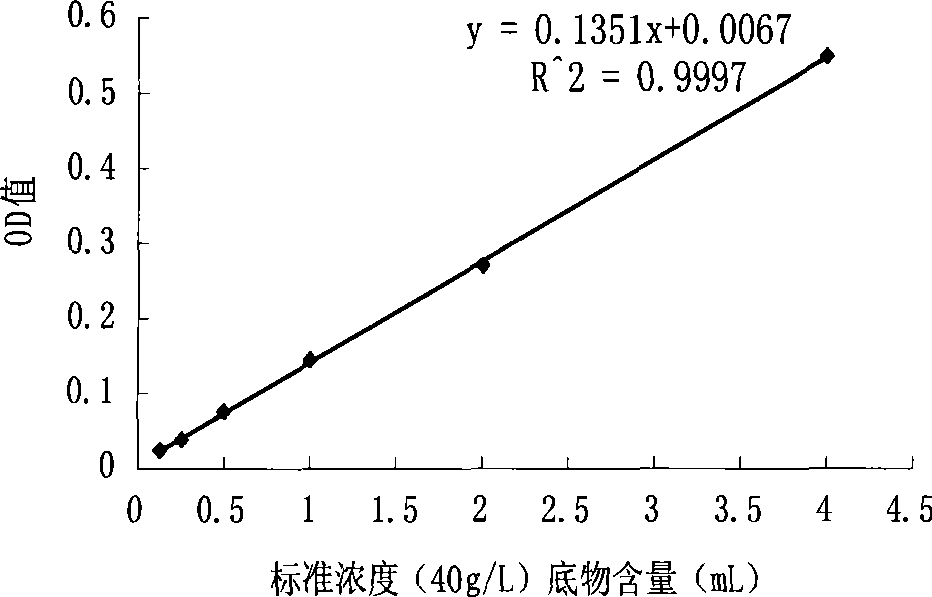

[0020] Preparation of highly concentrated bacterial liquid:

[0021] Inoculate the strain Bacillus pasteurii into the beef extract peptone culture solution, each liter of the culture solution contains 4-6g of peptone and 2-4g of beef extract, and control the pH to 6-8, culture at 30°C for 16-24h, Take out and centrifuge at 5000-8000rpm for 5-8min to get the lower layer to obtain highly concentrated bacterial liquid, the strain concentration is 2×10 9 ~2×10 11 cell / mL.

Embodiment 1

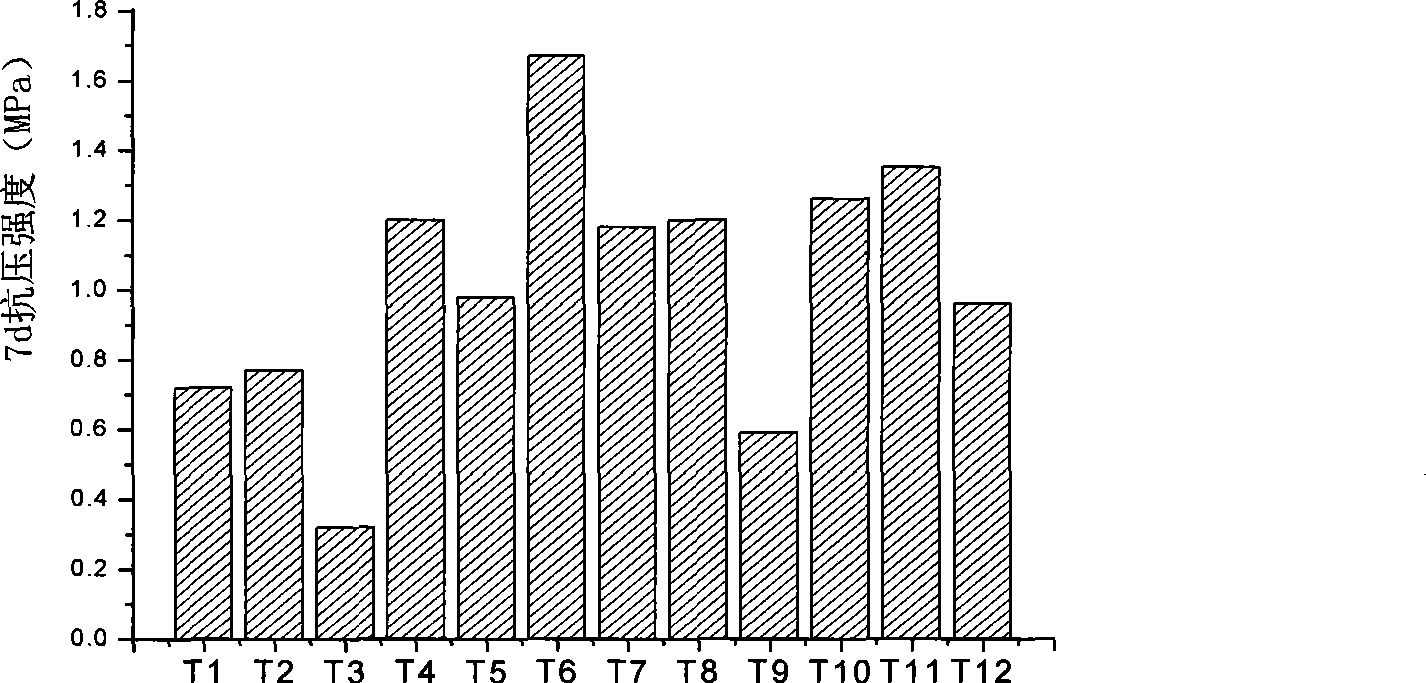

[0023] Mix the soil with lime that occupies 3% to 7% of the mass of the soil, and the strain concentration is 2×10 11 Cell / mL of highly concentrated bacterial liquid 6mL, urea 4.8g, water, and supernatant were combined separately, wherein the supernatant was the supernatant obtained by centrifugation when preparing the highly concentrated bacterial liquid, and the test was carried out instead of water, as shown in Table 2. After uniform mixing, it is compacted, demoulded and cured in a constant temperature room at 20°C. Three specimens are molded for each group, and the compressive strength is tested after 7 days, as shown in Table 3.

[0024] Table 2 Scheme design of soil stabilization by microbial technology

[0025]

[0026] Table 3 7-day compressive strength of soil specimens in each group

[0027]

[0028] According to the test, the highest 7-day compressive strength is the T6 (soil + bacteria + urea solution) group, and the lowest strength is th...

Embodiment 2

[0030] For the formula of the T12 group, another group of test pieces T12' was used as a control: the concentration of the strain was 2×10 11 Add 6mL of cell / mL high-concentration bacterial solution into the dry soil, and add 50mL of freshly prepared culture solution, each liter of the culture solution contains 5g of peptone and 3g of beef extract, let it stand for 4 days and 8 days respectively, and then mix it with dry soil 5.2g of lime with 3% mass and 4.8g of urea were molded, and the strength of the two groups of specimens was tested as shown in Table 4.

[0031] Table 4 7-day compressive strength of two groups of specimens

[0032]

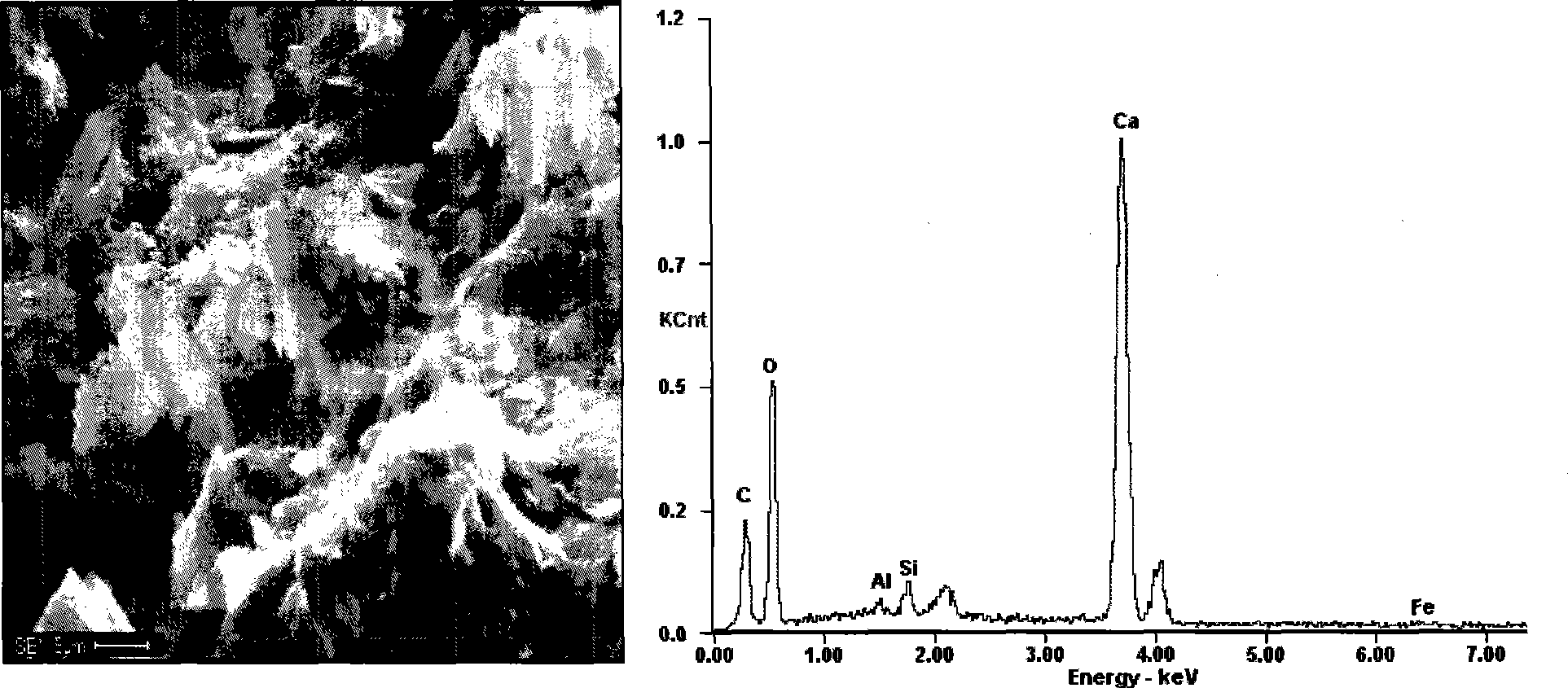

[0033] According to the formula of T12', molded according to the same method, the compressive strength measured 4 days and 8 days respectively reached 1.22, 1.16MPa, which is about 27% higher than that of the direct molding in the T12 group, and about 70% higher than that of the original plain soil. %. This is because the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com