SOI wafer manufacturing method and SOI wafer

一种制造方法、晶片的技术,应用在半导体/固态器件制造、电气元件、电固体器件等方向,能够解决晶片滑移位错、SOI晶片质量恶化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Hereinafter, although the Example of this invention is illustrated and this invention is demonstrated more concretely, this invention is not limited to these Examples.

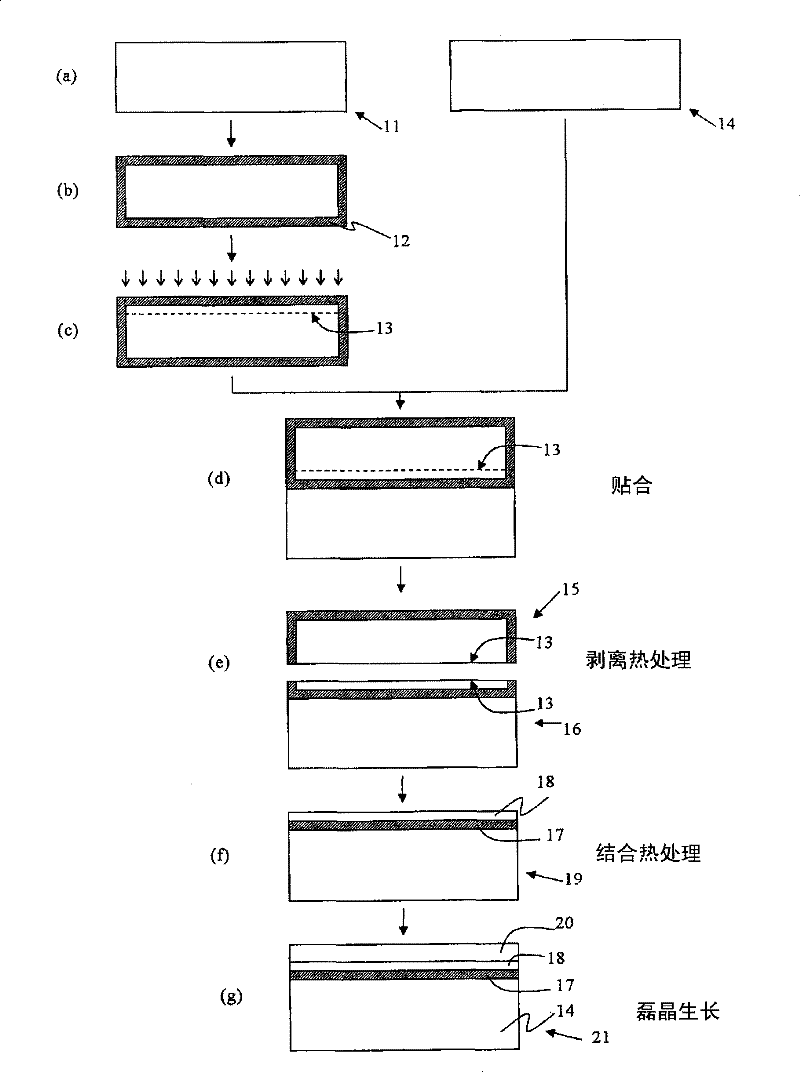

[0070] in accordance with figure 1 , a method of producing an SOI wafer serving as a substrate by an ion implantation lift-off method will be described.

[0071] Four thin disk-shaped wafers of CZ single crystal silicon substrates (diameter 200 mm (8 inches), thickness 625 μm) with an oxygen concentration of 20 ppma were prepared, and two were used as a bonding wafer and a base wafer.

[0072] Next, the two bonded wafers are heat-treated in an oxidizing environment to form an oxide film on the entire surface of the wafer. At this time, the time of the heat treatment was adjusted so that the thickness of the oxide film was 145 nm. For this bonded wafer, with a doping amount of 10×10 16 / cm 2 , and by adjusting the implantation energy to make the implantation depths of 195nm and 215nm, hydrogen ion im...

Embodiment 2

[0077] Embodiment 2, comparative example

[0078] Next, seven SOI wafers serving as substrates were prepared by the same method as in Example 1 (implantation depth of 215 nm), and the thickness of the oxide film and the thickness of the SOI layer were adjusted so that the surface reflectances were respectively 30% to 95%. On these SOI wafers serving as substrates, an epitaxial layer of 1000 nm was grown under the conditions of a reaction temperature of 1050° C. and a reaction time of 30 seconds, thereby producing an SOI wafer.

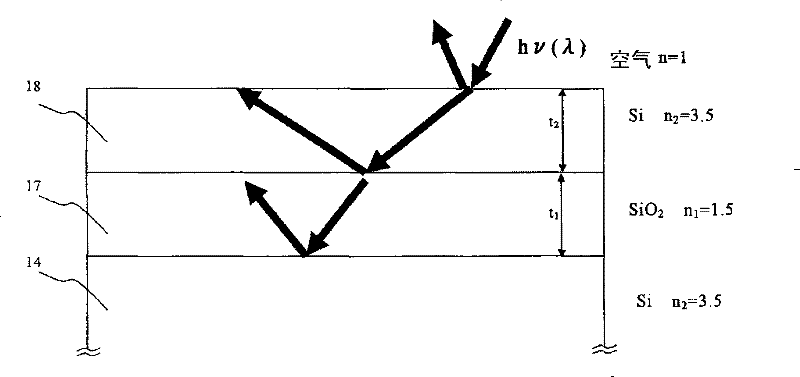

[0079] The relationship between the total slip length measured after epitaxial growth and the reflectivity of the SOI wafer before epitaxial growth is shown in Figure 5 . In SOI wafers with a reflectivity of more than 80%, the total slip length may exceed the allowable value, that is, 100 mm. However, in SOI wafers with a reflectivity of less than 80%, the total slip length is below the allowable value. Almost zero below 70%. When the reflectance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com