Synthesis optimizing and scheduling system of energy system

A technology of optimal scheduling and system integration, applied in the energy industry, comprehensive factory control, sustainable manufacturing/processing, etc., can solve the problem of backward automation of pulp and paper production energy scheduling, lack of understanding of energy scheduling methods, and waste of energy consumption in industrial production. and other problems, to ensure the rational operation of production economy, reduce subjectivity and limitations, and reduce energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

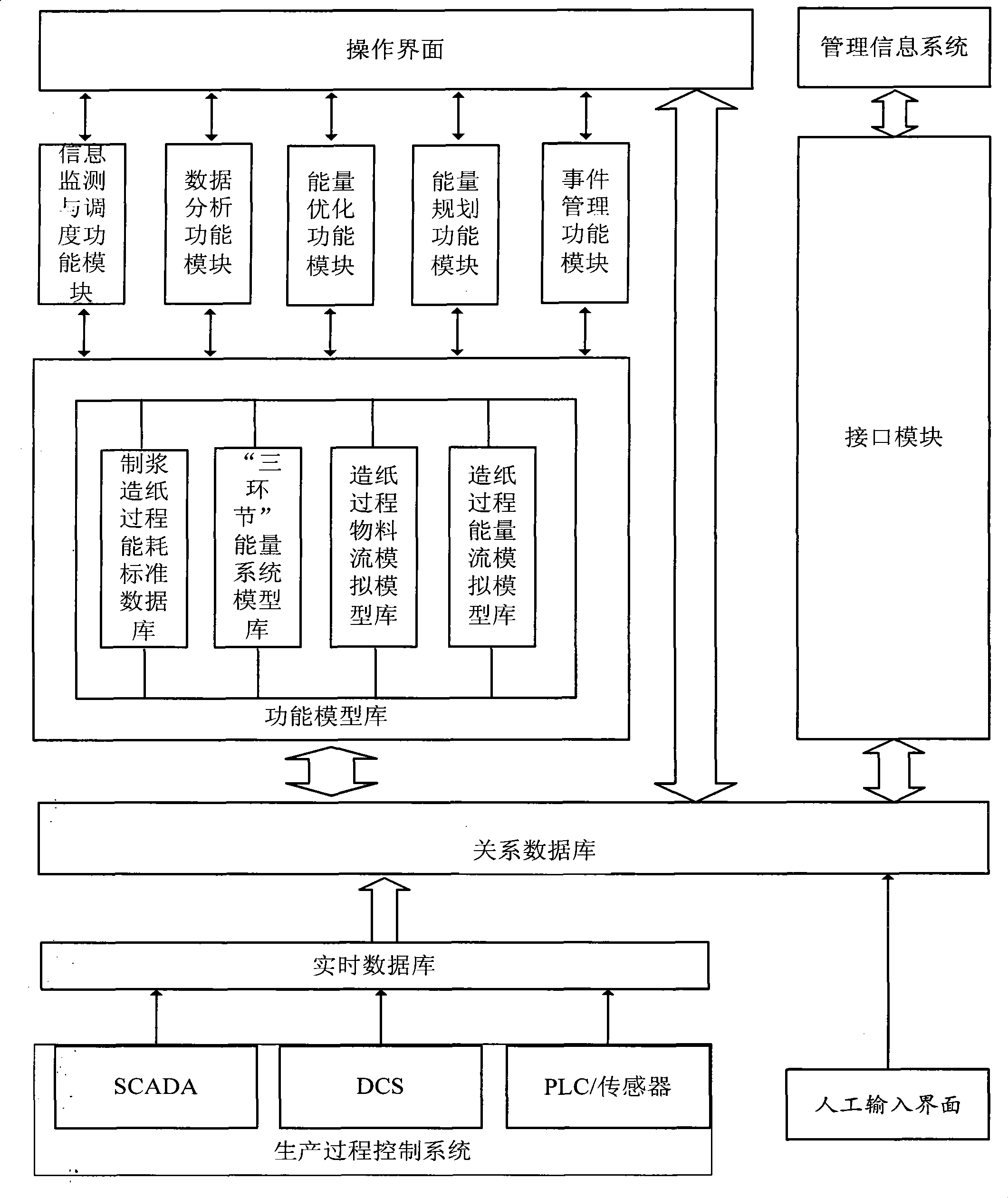

[0019] Such as figure 1 As shown, the energy system comprehensive optimization scheduling system of the present invention is connected with the management information system and the production process control system respectively, including an operation interface, an information monitoring and scheduling function module, a data analysis function module, an energy optimization function module, an energy planning function module, Event management function module, function model library, relational database, real-time database, interface module and manual input interface; among them, information monitoring and scheduling function module, data analysis function module, energy optimization function module, energy planning function module and event management function module Both are connected to the operation interface and functional model library; the relational database is connected to the operation interface, functional model library, real-time database and manual input interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com