Bacterial fed-batch anaerobic ammonium oxidation apparatus and technology thereof

A technology of anammox and anammox bacteria, which is applied in the field of strain fed anammox equipment, can solve the problems of unfavorable growth and proliferation of anammox bacteria, sensitive environmental conditions, long doubling time, etc. , to achieve the effect of improving the volume conversion efficiency and operation stability, shortening the start-up time and speeding up the start-up process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

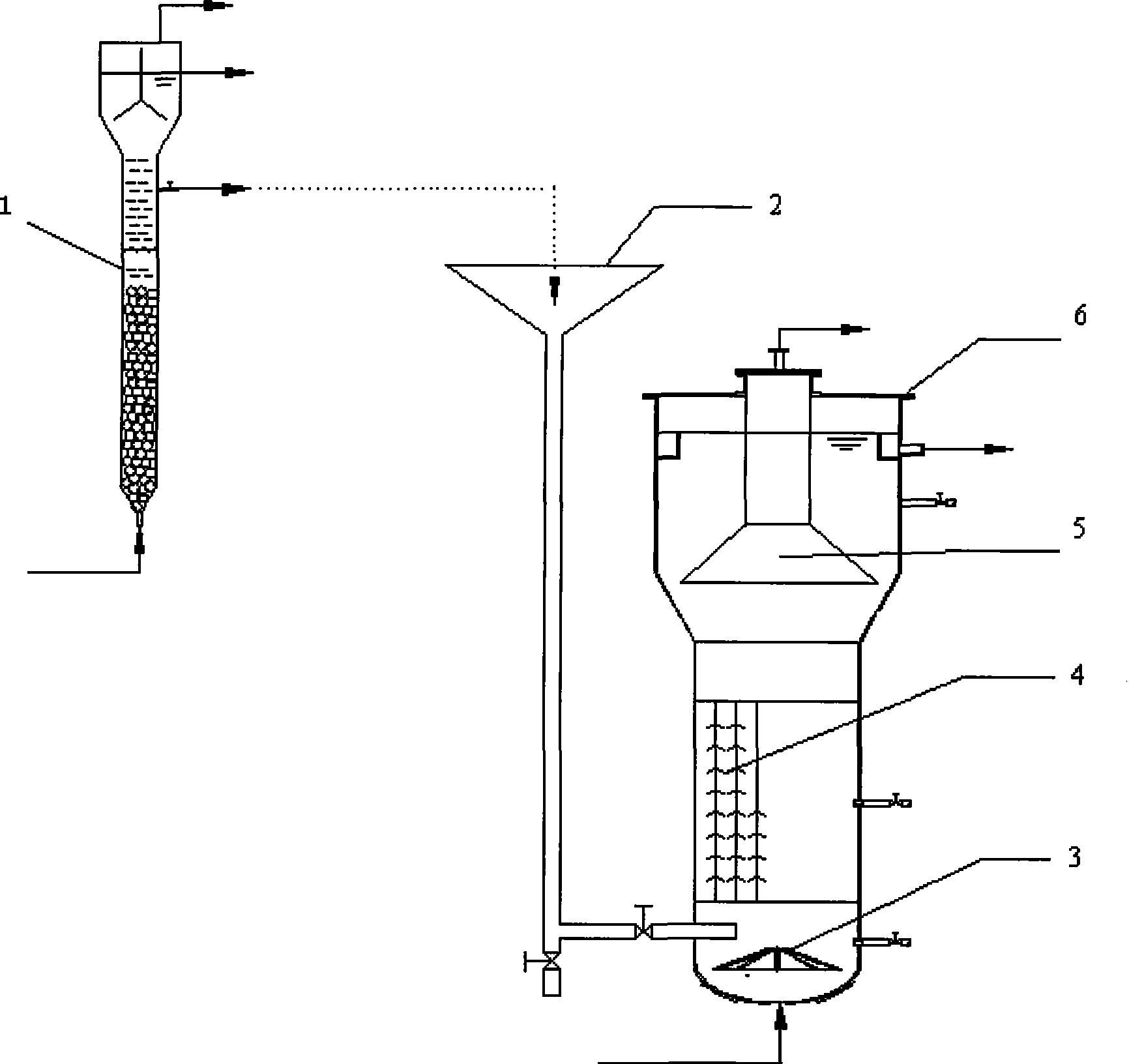

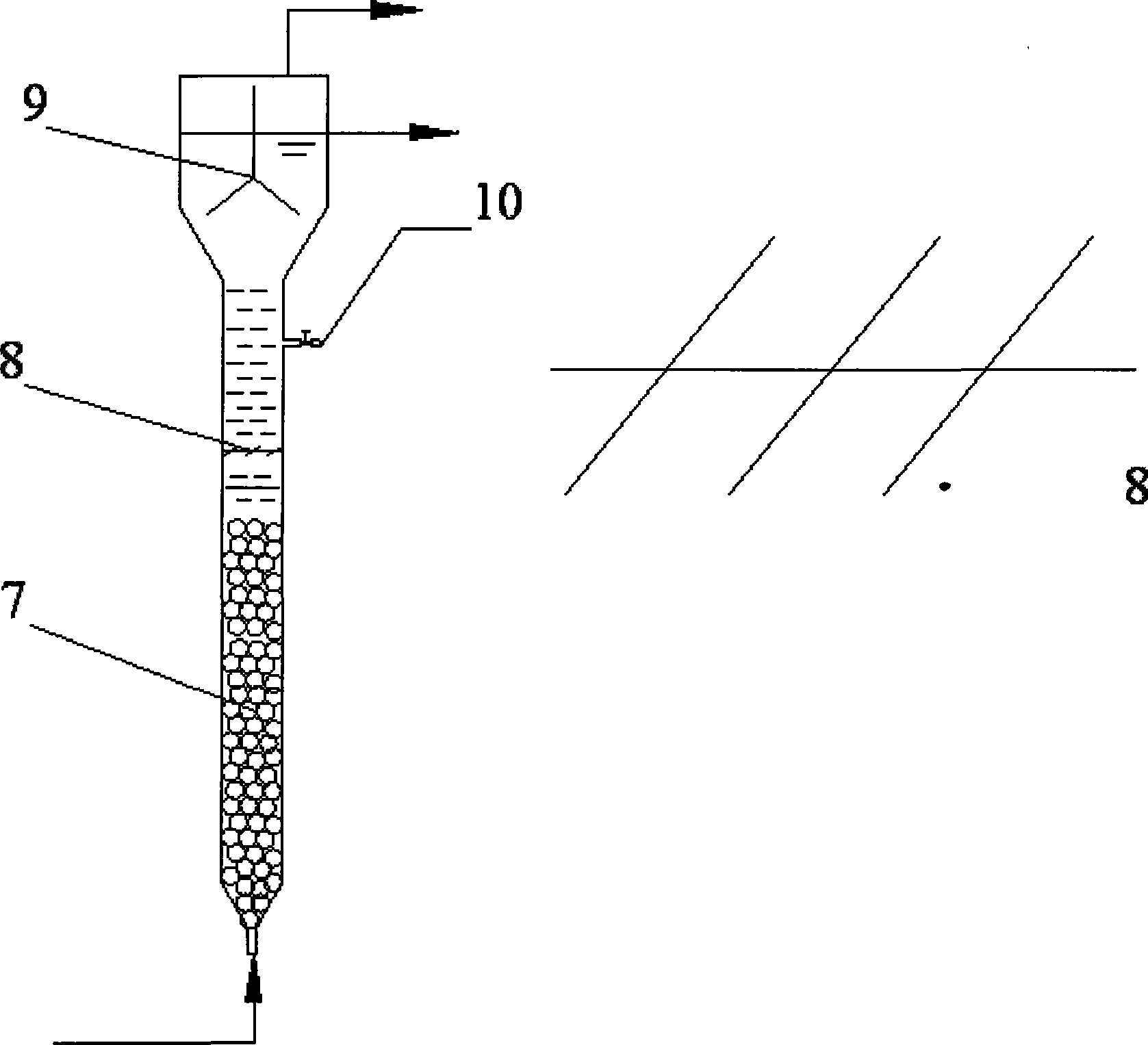

[0015] Such as figure 1 , 2 As shown, the strain fed anammox device includes anammox bacteria seed tank 1 and anammox reactor 6, anammox bacteria seed tank 1 includes a reaction zone and a precipitation zone, and the reaction zone is equipped with Fixed packing 7, partition baffle 8 are arranged, the second three-phase separator 9 is provided in the settling area, and the anammox bacteria seed tank 1 top is provided with a sludge discharge pipe 10; the anammox reactor 6 includes a reaction area and In the sedimentation area, the reaction area is provided with a swirling water distributor 3 and elastic packing 4, the first three-phase separator 5 is provided in the sedimentation area, and the bottom of the anammox reactor 6 is provided with a self-flowing strain feeding device 2, The anammox bacteria seed tank 1 is connected with the anammox reactor 6 through the mud discharge pipe 10 and the self-flowing strain feeding device 2, and the anammox bacteria seed tank 1 and the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com