Method for measuring mercury cadmium telluride material pn junction depth

A mercury cadmium telluride, pn junction technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of long test process, complicated operation, difficult to achieve accurate test results, etc., to achieve simple test methods, test The results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

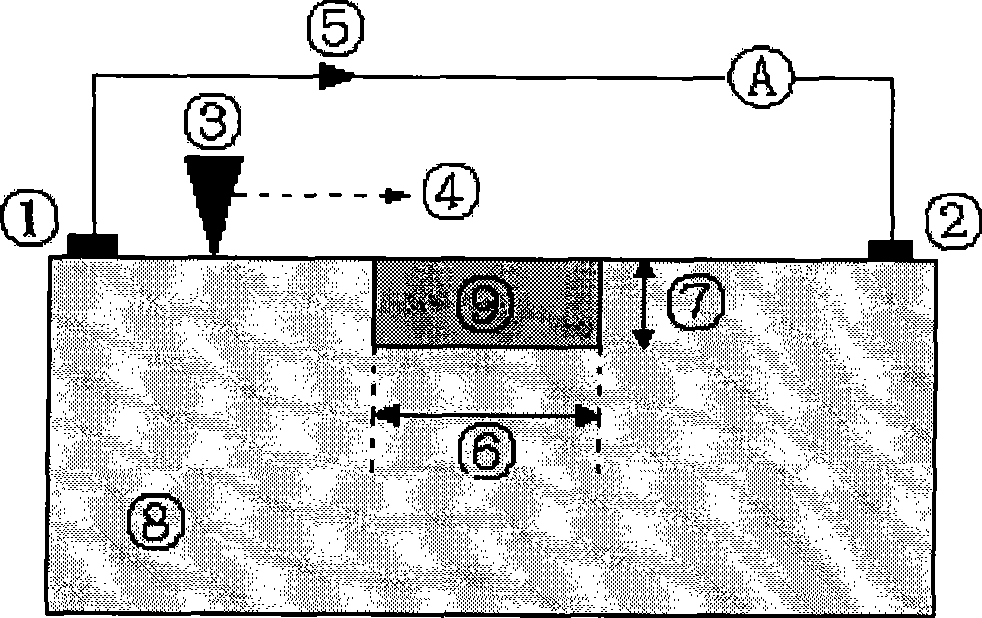

[0017] A specific implementation of the present invention will be described in detail below:

[0018] 1. Production of ohmic electrode: LBIC measurement requires a good ohmic contact electrode. The production of ohmic electrode can use the general ohmic contact production method of mercury cadmium telluride semiconductor material, as follows:

[0019] a) Sample cleaning: first clean with trichloroethylene at 65°C for 20 minutes, then with ether at 65°C for 20 minutes, and then soak in acetone and ethanol at 65°C for 15 minutes. The above reagents are all analytically pure, and the cleaned sample surface is bright and clean.

[0020] b) Lithography pattern: the areas where the metal film needs to be deposited and the areas that do not need to be deposited are formed by a conventional lithography process

[0021] c) Metal film deposition: Place the photo-etched sample in an ion beam coating machine, and perform ion beam sputtering tin-gold film plating as an ohmic contact electrode....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com