Double feeding induction generator dual channel excitation control method based on dynamic synchronizing shaft system

A doubly-fed induction and excitation control technology, which is applied to control generators, control generators and control systems through magnetic field changes, and can solve problems such as complex excitation control systems, inaccurate mathematical models, and poor transient stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

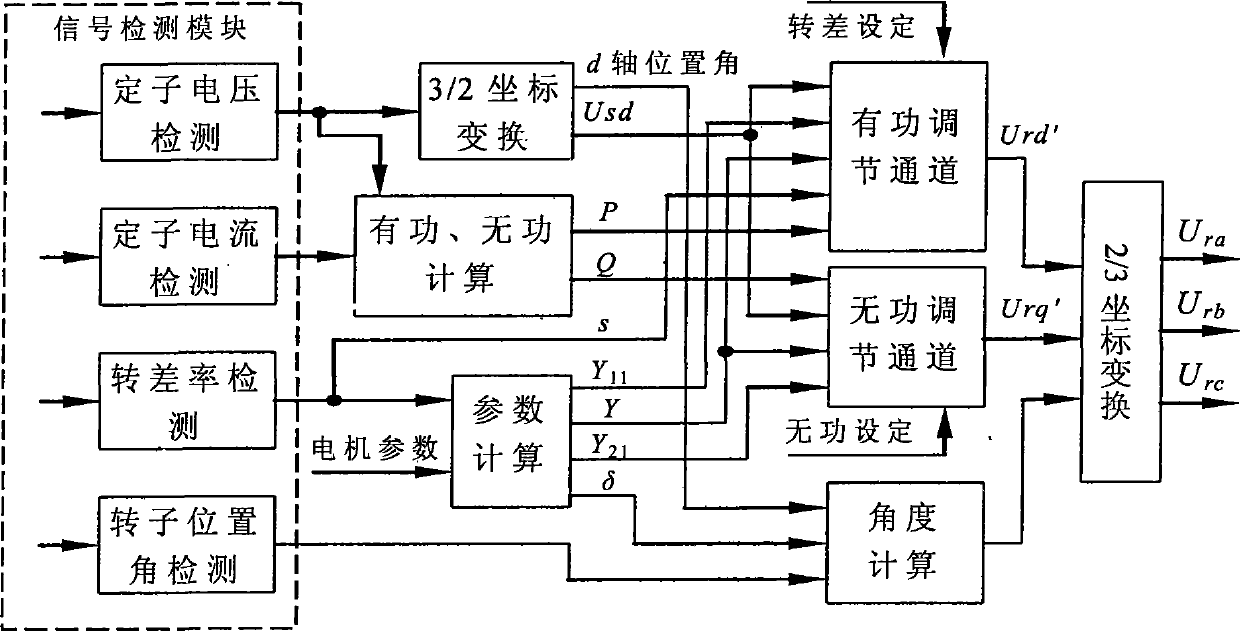

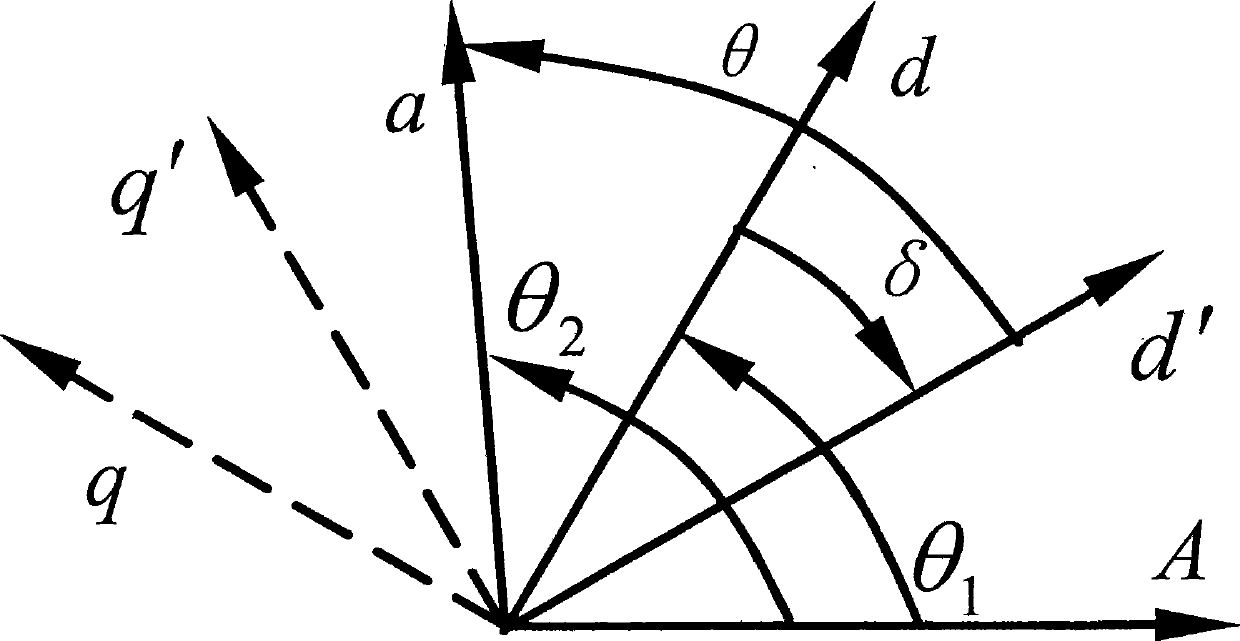

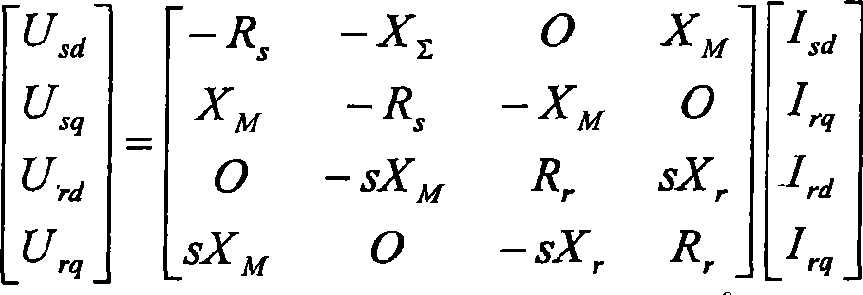

[0066] in the attached figure 1 Among them, the doubly-fed induction generator excitation control method based on dynamic synchronous shafting can be implemented in the following ways.

[0067] a) Signal detection part:

[0068] AC signal detection: Sampling 32-point signals at equal intervals in the three-phase voltage and current of the doubly-fed induction generator stator, using the Fourier algorithm to calculate the voltage and current phasors represented by real and imaginary parts, and realize AC signal detection detection;

[0069] Slip detection: After the stator voltage is shaped into a square wave signal, the synchronous speed can be obtained by measuring the period of the square wave signal; the rotor speed can be calculated by using the circle pulse and tooth pulse signals of the grating encoder disc; the rotor speed can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com