Method for preparing policosanol mixture by nonsolvent reduction method

A technology for preparing higher alkanols and higher alkanols is applied in the preparation of organic compounds, chemical instruments and methods, preparation of oxygen-containing compounds, etc., and can solve the problems of difficult control of reaction conditions, unfavorable safe production, increased production costs, etc. The effect of easy control of process conditions, low cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

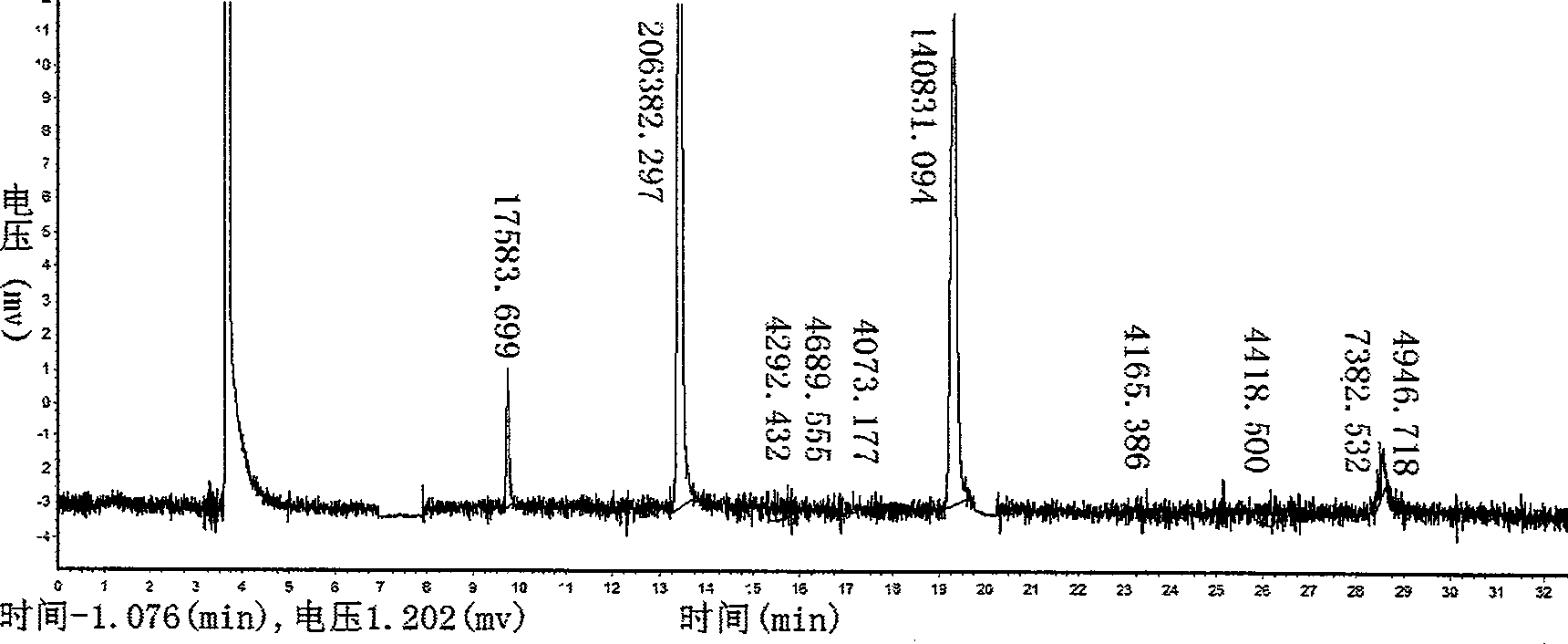

Image

Examples

Embodiment 1

[0031] A. Weigh 10 g of commercially available white wax, put it in a 200 ml beaker, heat it on an electric furnace to 84 ° C, then add 1.0 g of lithium aluminum hydride under continuous stirring, and keep the temperature for 10 minutes to obtain a mixture;

[0032] B. Slowly add 100g of tap water to the mixture in step A, continue stirring, heat to boiling, slowly add 1g of 0.5mol / L HCl solution, and heat to boiling for 10min;

[0033] C. When cooling to 50°C, the solid and liquid phases are separated, and the upper layer is taken out to obtain the crude product of the higher alkanol mixture;

[0034] D. Put the crude higher alkanol mixture taken out into 150g tap water, add 0.1g0.5mol / L HCl solution, heat and boil for 10min, then adjust the pH value to neutral with 0.1mol / L NaOH solution, and cool to room temperature , so that the solid and liquid phases are separated, the solid phase is the higher alkanol mixture product, and 9.5 g of the higher alkanol mixture product is o...

Embodiment 2

[0036] A. Weigh 20g of commercially available paraffin wax and put it into a 500ml beaker, heat it on an electric furnace to 100°C, then add 1.0g Ranny-Ni under the condition of continuous stirring, and keep the temperature for 60min to obtain the mixture;

[0037] B. Slowly add 400g of tap water to the mixture in step A, continue stirring, heat to boiling, add 10g of 0.5mol / L HCl solution, and heat to boiling for 20min;

[0038] C. When cooled to 55°C, the solid and liquid phases are separated, and the upper layer is taken out to be the crude product of higher alkanol mixture;

[0039]D. Put the crude product of the higher alkanol mixture taken out into 400g tap water, add 1.0g0.5mol / L HCl solution, heat and boil for 20min, adjust the pH value to neutral with 0.2mol / L NaOH solution, cool to normal temperature, and make solid , liquid phase separation, the solid phase is the higher alkanol mixture product, and the higher alkanol mixture product is weighed to obtain 19.3g, with...

Embodiment 3

[0041] A. Weigh 50g of commercially available white wax and put it in a 2000ml stainless steel pot, heat it on an electric stove to 120°C, add 1.6g of lithium aluminum hydride under continuous stirring, and keep the temperature for 100min to obtain a mixture;

[0042] B. Slowly add 1500g of tap water to the mixture in step A, continue stirring, heat to boiling, slowly add 50g of 0.5mol / L HCl solution, and heat to boiling for 30min;

[0043] C. When cooling to 60°C, the solid and liquid phases are separated, and the crude product of the higher alkanol mixture in the upper layer is taken out;

[0044] D, put the crude product of the higher alkanol mixture taken out into 1500g tap water, add 5g0.5mol / L HCl solution, heat and boil for 30min, adjust the pH value to neutrality with 0.5mol / L NaOH solution, cool to normal temperature, make solid , liquid phase separation, the solid phase is the product of the higher alkanol mixture, and 47.0 g of the higher alkanol mixture was obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com