Nickel iron intermediate alloy and melting and purification treatment method thereof

A master alloy and purification treatment technology, which is applied in the medium frequency induction furnace to smelt nickel-iron master alloy for purification treatment. In the field of nickel-iron master alloy, it can solve the problem of unsuitable smelting of low thermal expansion nickel-iron alloy, low purity of nickel-iron, Problems such as high impurity content of ferronickel, to achieve the effect of favorable recycling, pure alloy and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

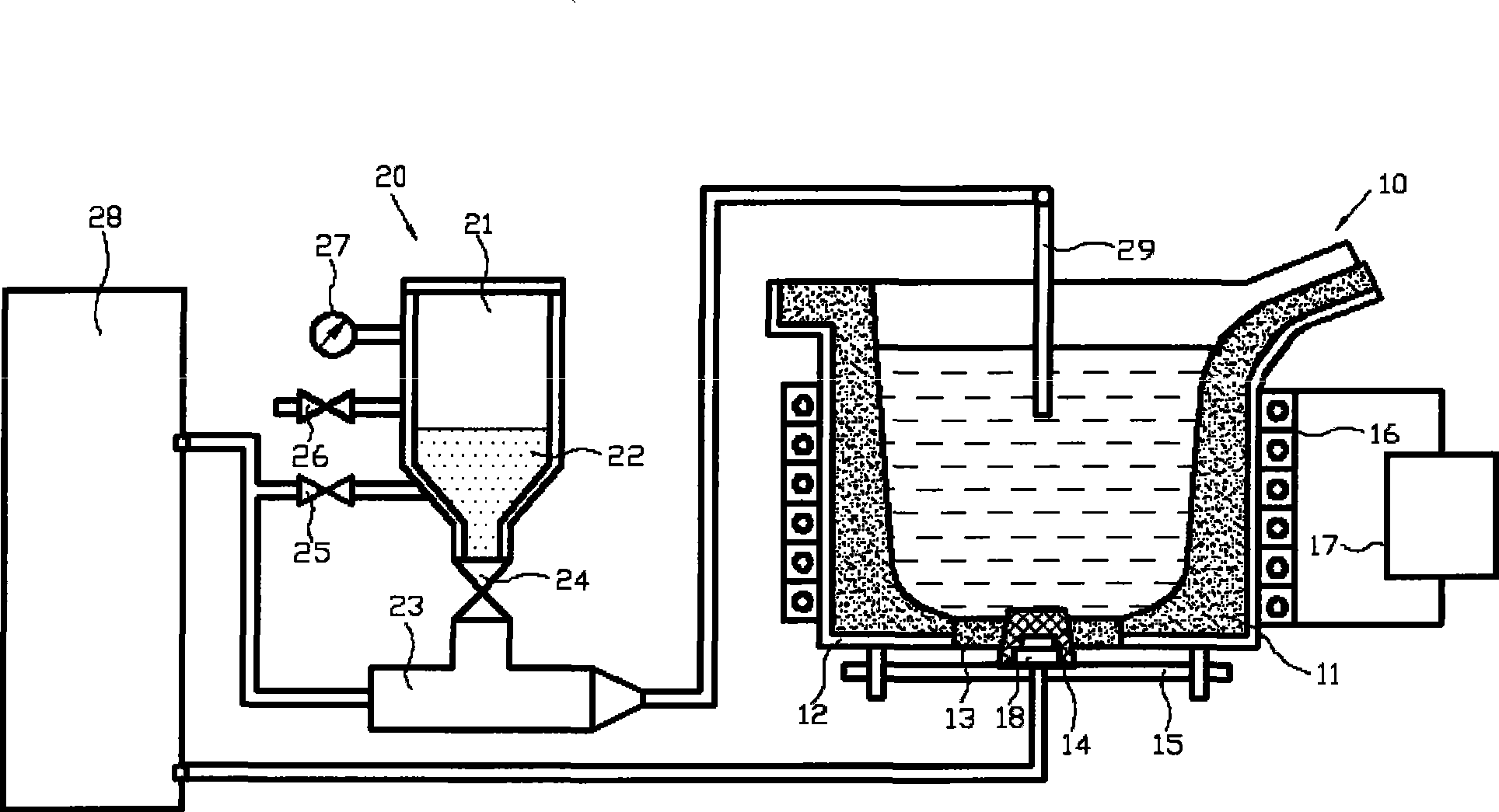

[0030] figure 1 The structure of the induction smelting purification treatment furnace for implementing the present invention is shown, and the furnace is mainly composed of an intermediate frequency furnace 10 and a powder spraying device 20 .

[0031] The intermediate frequency furnace 10 is mainly composed of a crucible 11 , a furnace shell 12 , an induction coil 16 and a variable frequency power supply 17 . A hollow seat brick 13 is installed at the middle position of the bottom wall of the intermediate frequency furnace. Qi; in the hollow hole of seat brick 13, air-permeable brick 14 is housed, and the top surface of this air-permeable brick 14 is higher than the furnace chamber bottom surface of intermediate frequency furnace 10 a short distance, and the bottom surface of this air-permeable brick 14 is higher than the bottom furnace shell of intermediate frequency furnace 10 For a short distance, there is a stepped blind hole 18 for containing gas at the bottom of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com