Exterior insulation system for polyphenyl plate thin plastering exterior wall and construction method thereof

A technology for external wall thermal insulation and polystyrene board, which is applied in thermal insulation, building components, covering/lining, etc., can solve problems such as difficulty in air permeability, ensure thermal performance, avoid condensation, prevent foaming and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

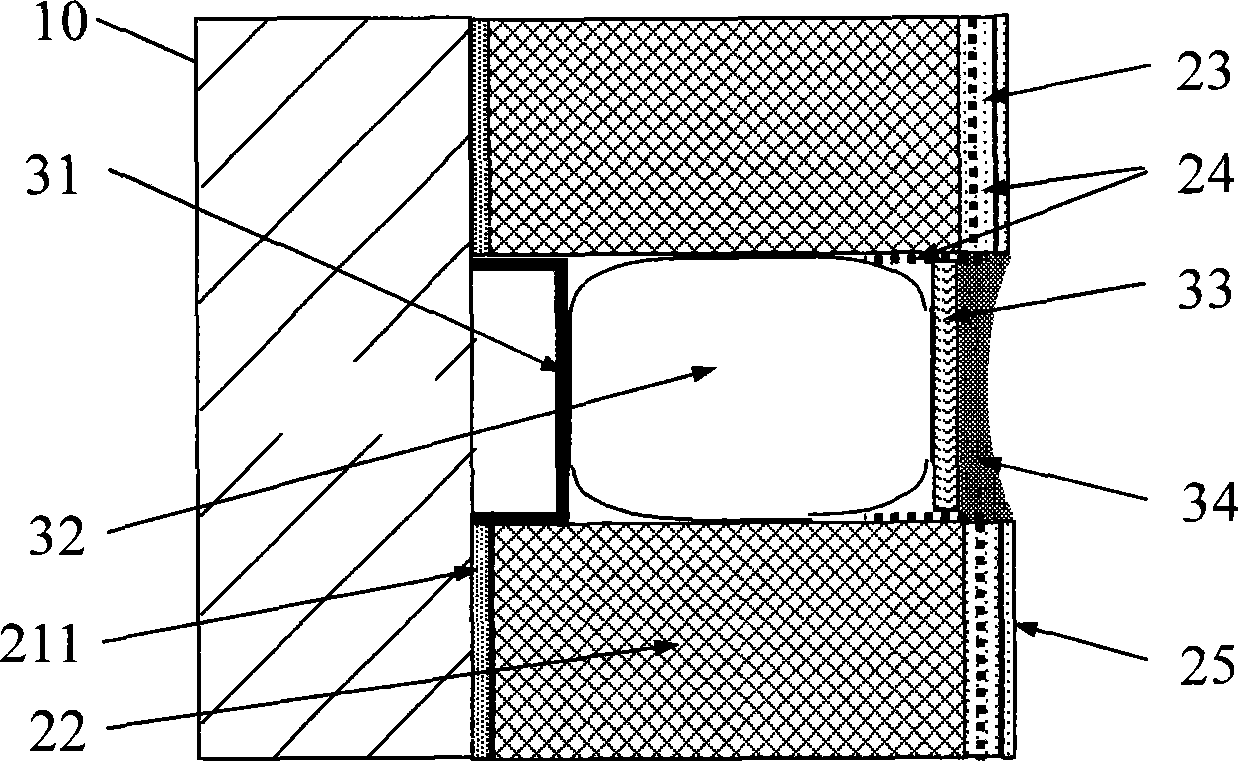

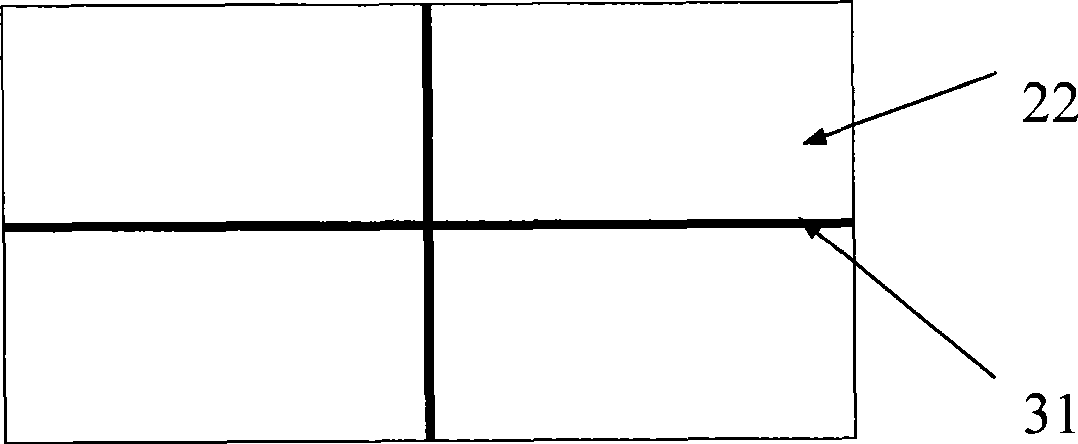

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 10 and Figure 12 , the construction base wall 10 is a concrete structure, the wall is 35m high, and the parapet 11 has no overhanging eaves.

[0041] Adopt EPS board 22, length 1200mm, width 600mm, thickness 30mm. Paste vertically on the long side.

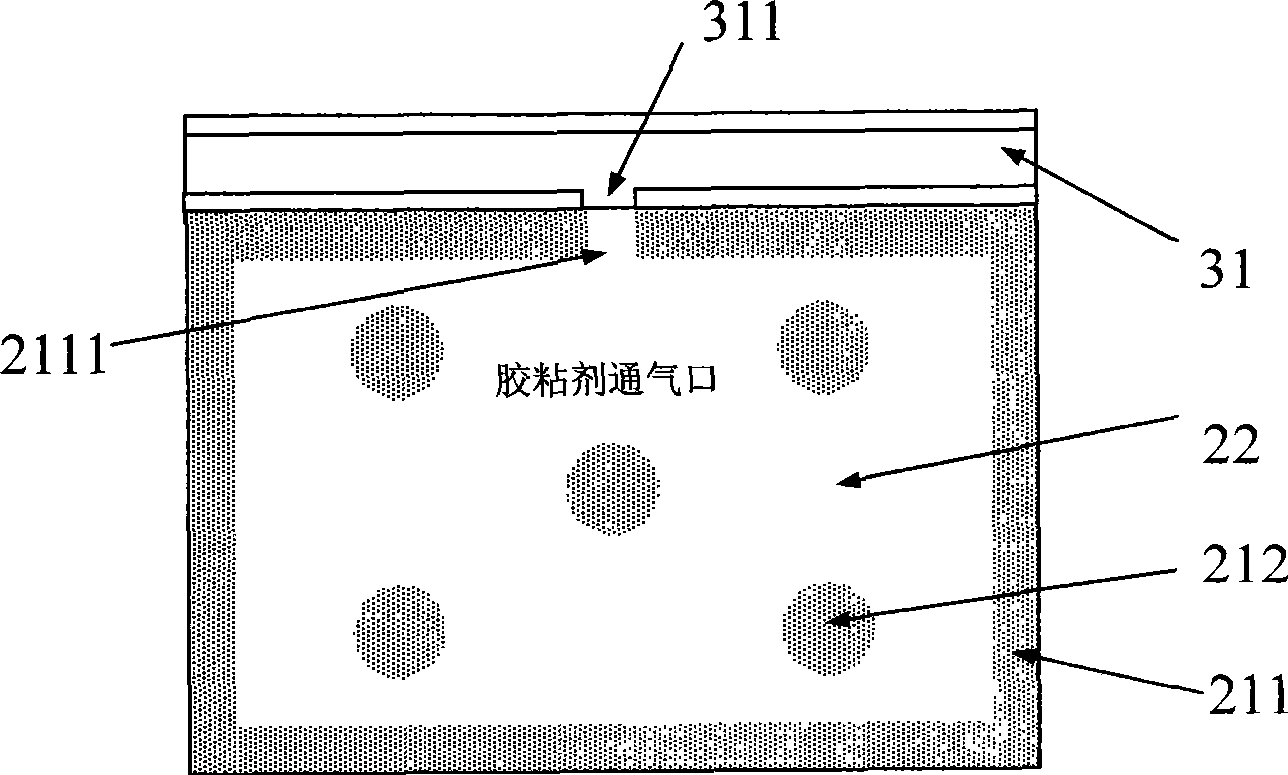

[0042] Apply the adhesive to the back of the EPS board 22, apply a circle of 50 mm wide strip adhesive layer 211 on the frame, and evenly apply five dot-shaped adhesive layers 212 with a diameter of 100 mm in the middle of the board, and the thickness of the adhesive is 2 mm. Leave a vent 2111 with a width of 50 mm at the central adhesive above the EPS board 22 . Paste the EPS board 22 on the base wall 10, and maintain it for 1 day.

[0043]The exhaust groove 31 is made of PVC material, with a width of 10mm, a height of 6mm, and a wall thickness of 1mm. Vent 311 is provided at the position corresponding to the posi...

Embodiment 2

[0053] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 , Figure 11 and Figure 12 , the construction base wall 10 is a concrete structure, the wall is 35m high, and the top of the parapet 11 is provided with overhanging eaves 111 .

[0054] Adopt XPS board 22, length 900mm, width 600mm, thickness 20mm. Paste the long side horizontally.

[0055] Apply the adhesive to the back of the XPS board 22, apply a circle of 60mm wide strip adhesive layer 211 on the frame, and evenly apply five dot-shaped adhesive layers 212 with a diameter of 100mm in the middle of the board, and the thickness of the adhesive is 2mm. A vent 2111 with a width of 100 mm is left at the central adhesive above the XPS board 22 . Paste the XPS board 22 on the base wall 10 and maintain it for 1 day.

[0056] The exhaust groove 31 is made of PVC material, with a width of 10mm, a height of 6mm, and a wall thickness of 1mm. Vent 311 is arranged on the exhaust groove 31 arranged horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com