Flexible color changing neon lamp for simple thin LED

A technology of light-emitting diodes and diodes, which is applied in the direction of semiconductor devices, light sources, electric light sources, etc. The effect of saving material cost and production cost, volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

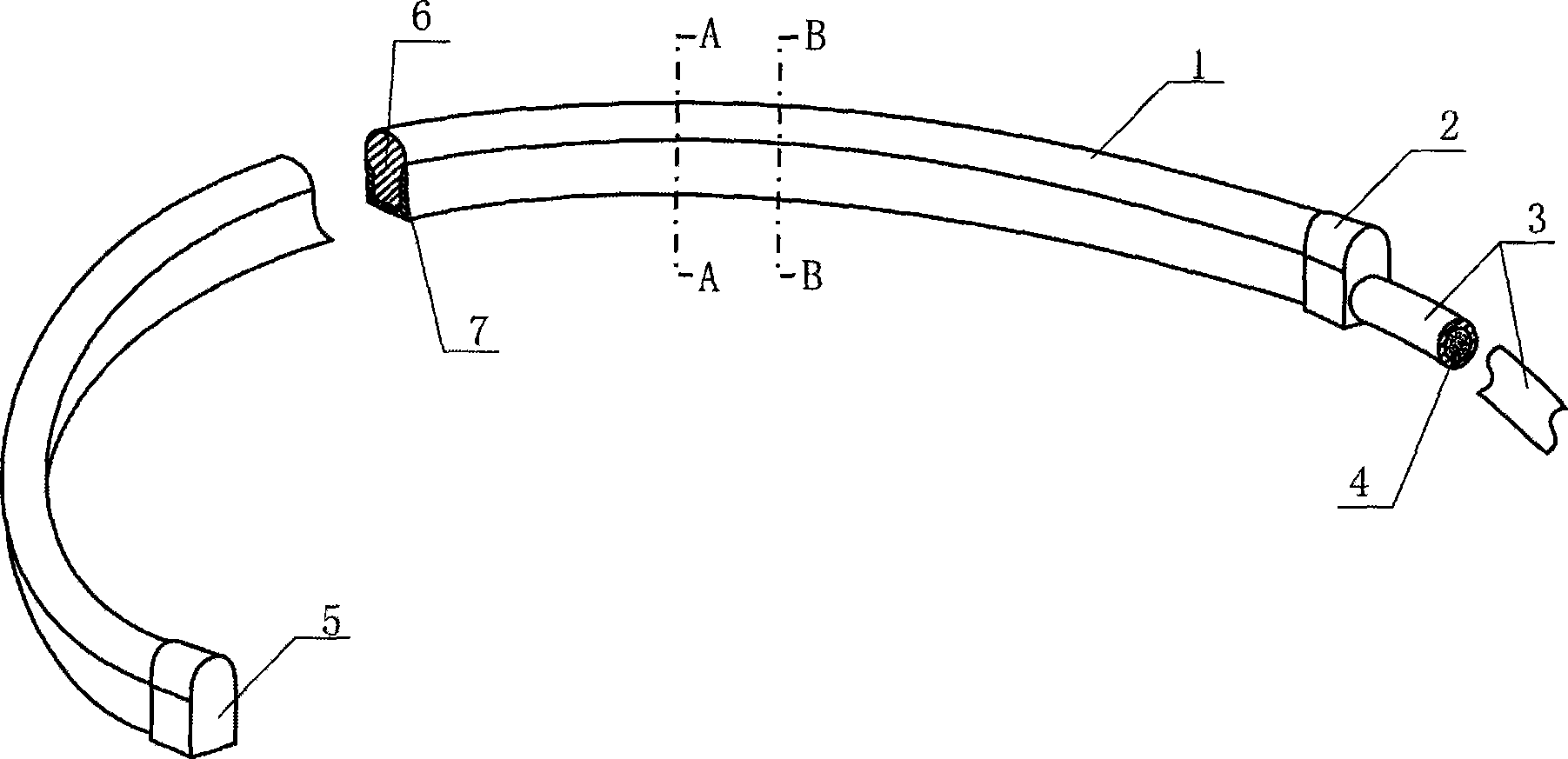

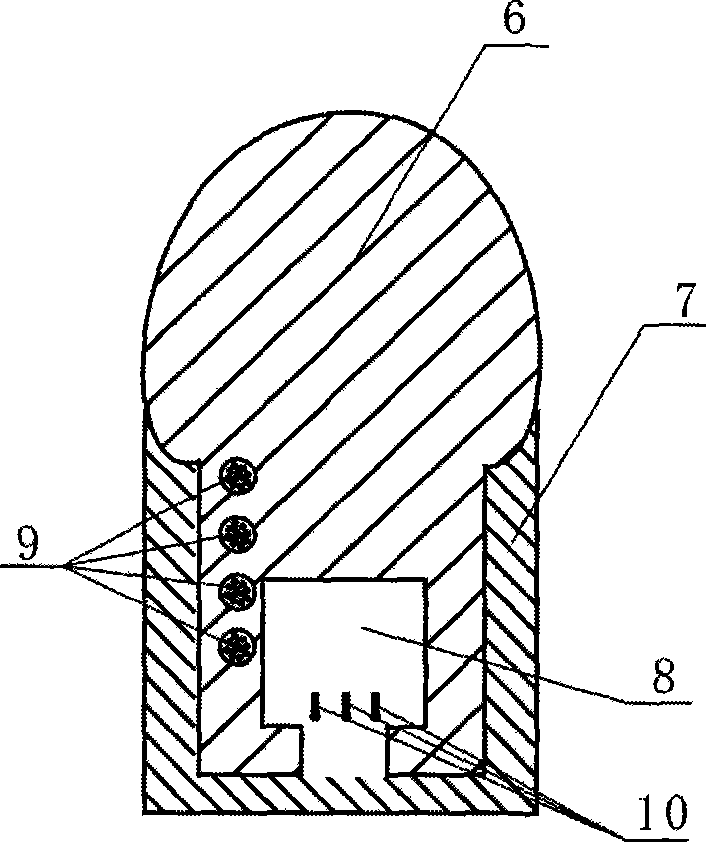

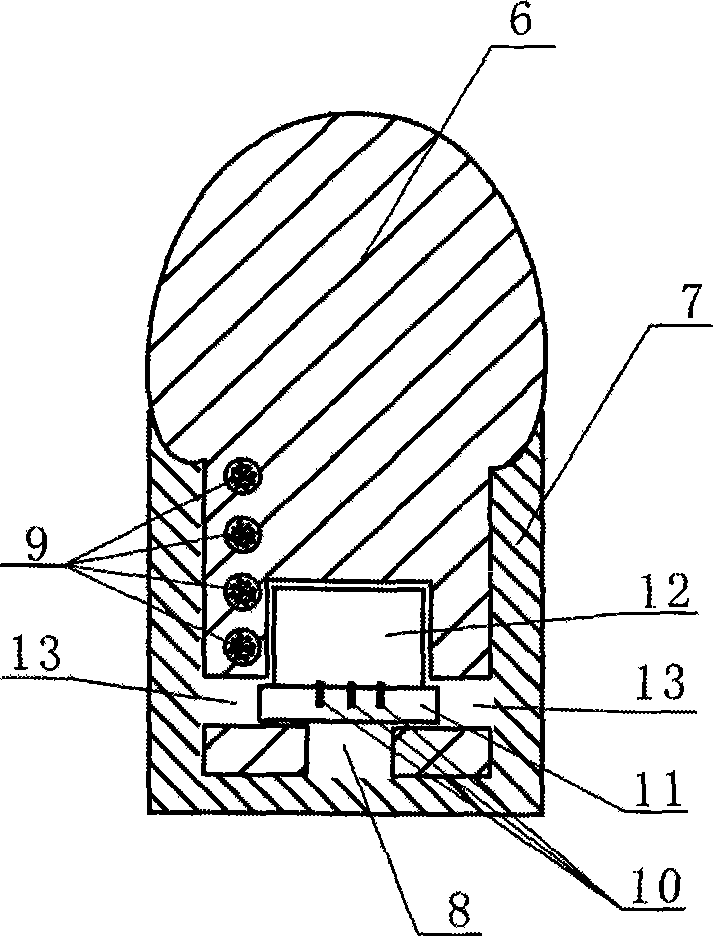

[0028]Below in conjunction with accompanying drawing, the present invention will be further specifically described:

[0029] Such as figure 1 , figure 2 and image 3 as shown, figure 2 It is a cross-sectional view of a part of the lamp tube 1 located between two adjacent diode light emitting units, image 3 It is a cross-sectional view of a part of the lamp tube 1 within the scope of the diode light emitting unit. The present invention includes a core wire 6, a diode light emitting device, a copper strand 9, an opaque coating layer 7, and a DC power supply device. Such as Figure 4 As shown, the figure only shows the structure of one of the core wires 6, combined with figure 2 , image 3 and Figure 4 , the core wire 6 is a translucent diffuser, a groove 8 coaxial with the core wire 6 and equal in length is provided under the core wire 6, the diode light-emitting device is installed in the groove 8, and the light-emitting surface of the diode light-emitting unit is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com