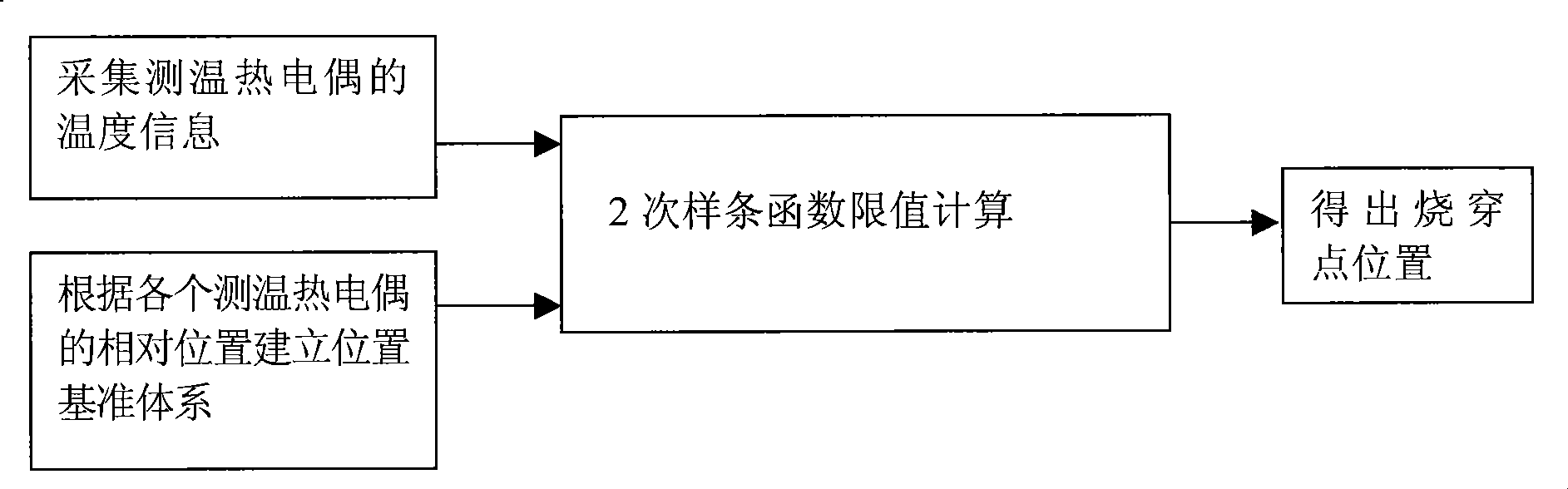

Burning through point localization method suitable for updraft sintering machine and positioning system thereof

A positioning method and technology of a sintering machine, which are applied to thermometers using electrical/magnetic components that are directly sensitive to heat, using electrical devices, using electromagnetic means, etc. Good smelting rate and desulfurization rate, improving smelting quality and saving energy and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

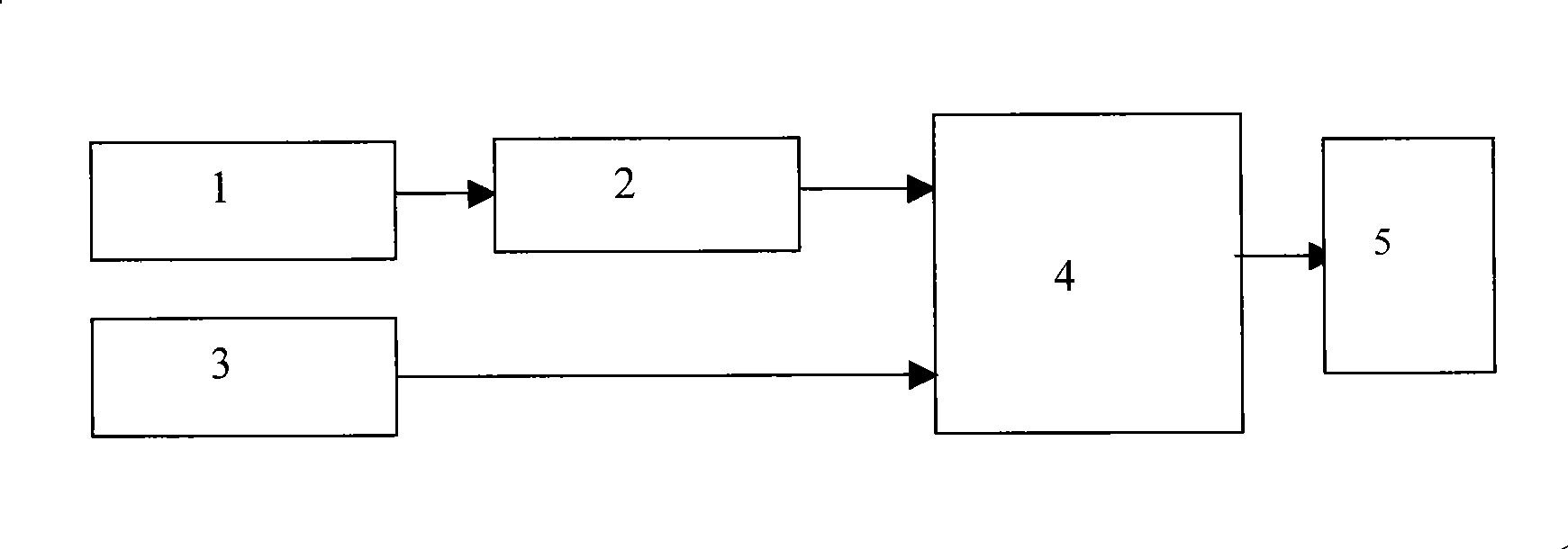

Method used

Image

Examples

Embodiment Construction

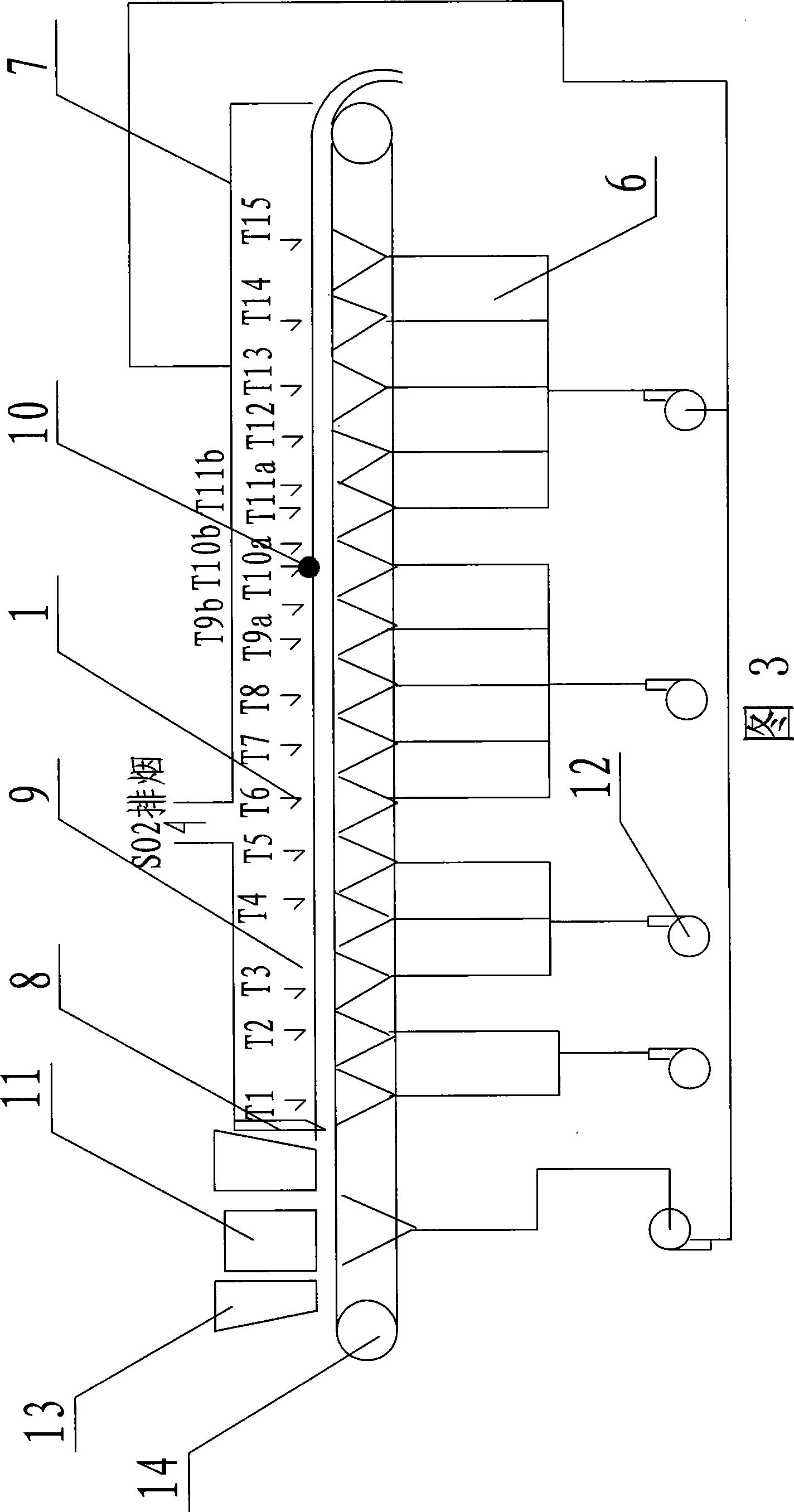

[0035]Refer to Figure 3 for the structure of the blower sintering machine. The temperature measuring thermocouple 1 is installed on the fume hood 7 to realize the function of knowing the sintering temperature of the material layer during the process. During operation, observe which temperature measuring thermocouple has the highest temperature. The burn-through point is in front of or behind it. Since the front and rear temperature measuring thermocouples are 1.5-3m apart, where is the burn-through point? Generally, it is manually operated to achieve the ideal empirical position, and there is no specific positioning. method, the accuracy is not high. And the present invention utilizes the installation position of temperature-measuring thermocouple 1 to set the relative position of standard for each temperature-measuring thermocouple, proposes quadratic spline function method, compares, sorts, calculates with control device 4 and paperless recorder , digital or screen real-time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com