Extraction method of heavy fraction of ft synthetic product from slurry bed reactor

A Fischer-Tropsch synthesis and slurry bed technology, applied in chemical instruments and methods, hydrocarbon production from carbon oxides, chemical/physical processes, etc., can solve problems such as forced shutdown and excessive pressure drop of the device, and reduce the difficulty , low density, prolonging the effect of operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The Fischer-Tropsch synthesis Fe-Cu-K catalyst prepared by the method disclosed in US5324335 was used for testing. In the slurry phase of the slurry bed reactor, the concentration of the catalyst is 30wt%, the particle size distribution range is 40-200μm, and the production capacity of the heavy fraction of the Fischer-Tropsch synthesis product is 30 tons / hour.

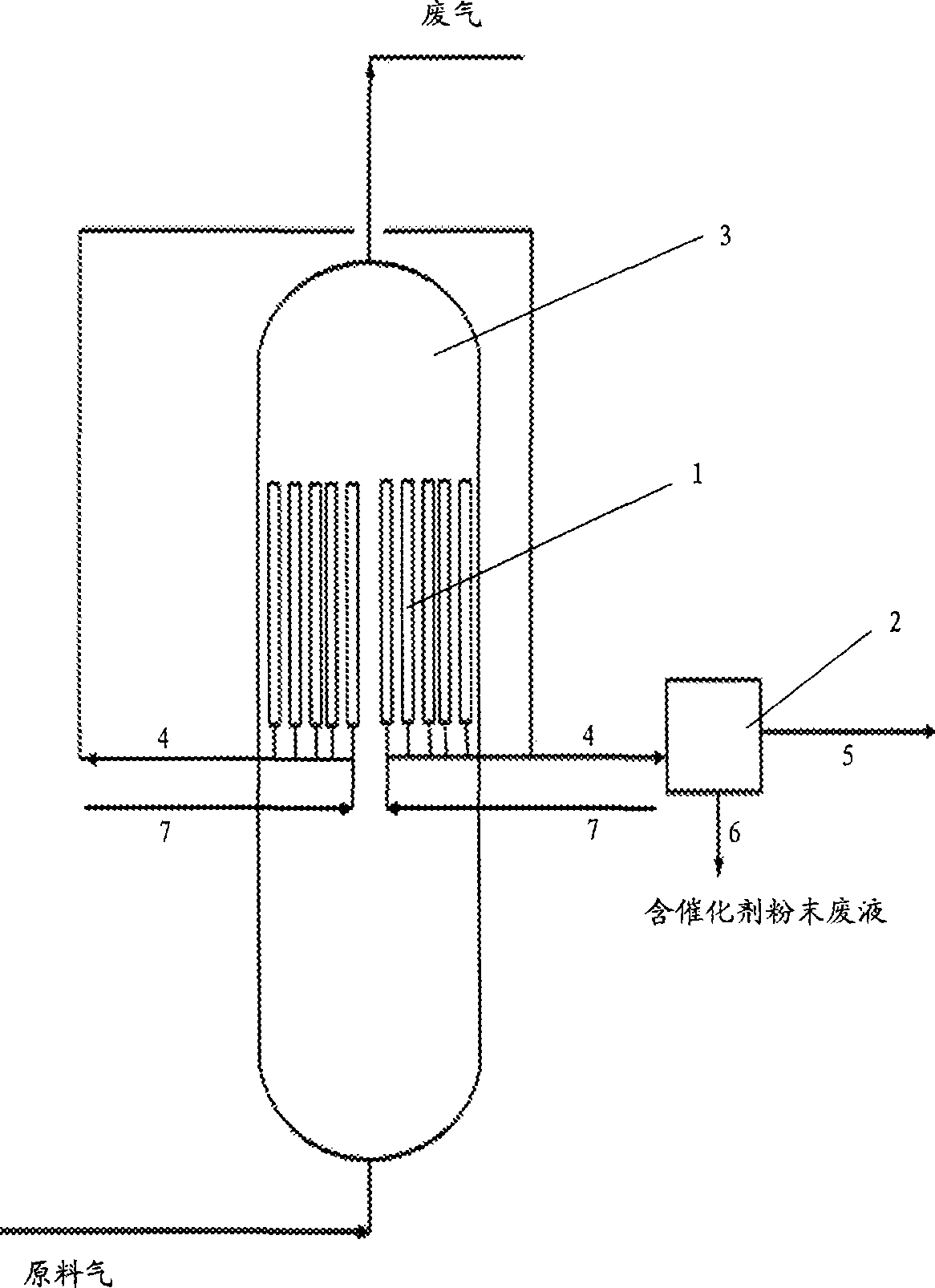

[0027] Such as figure 2 As shown, the SL50*800 asymmetric metal sintered filter rod 1 produced by Beijing Antai Technology Co., Ltd. is installed in the slurry bed reactor used. A total of 40 groups of filter rods are arranged, and each group is composed of 10 parallel filter rods, and the filter rods are evenly arranged in the radial direction of the reactor. The filtration precision of the filter rod is 25 μm.

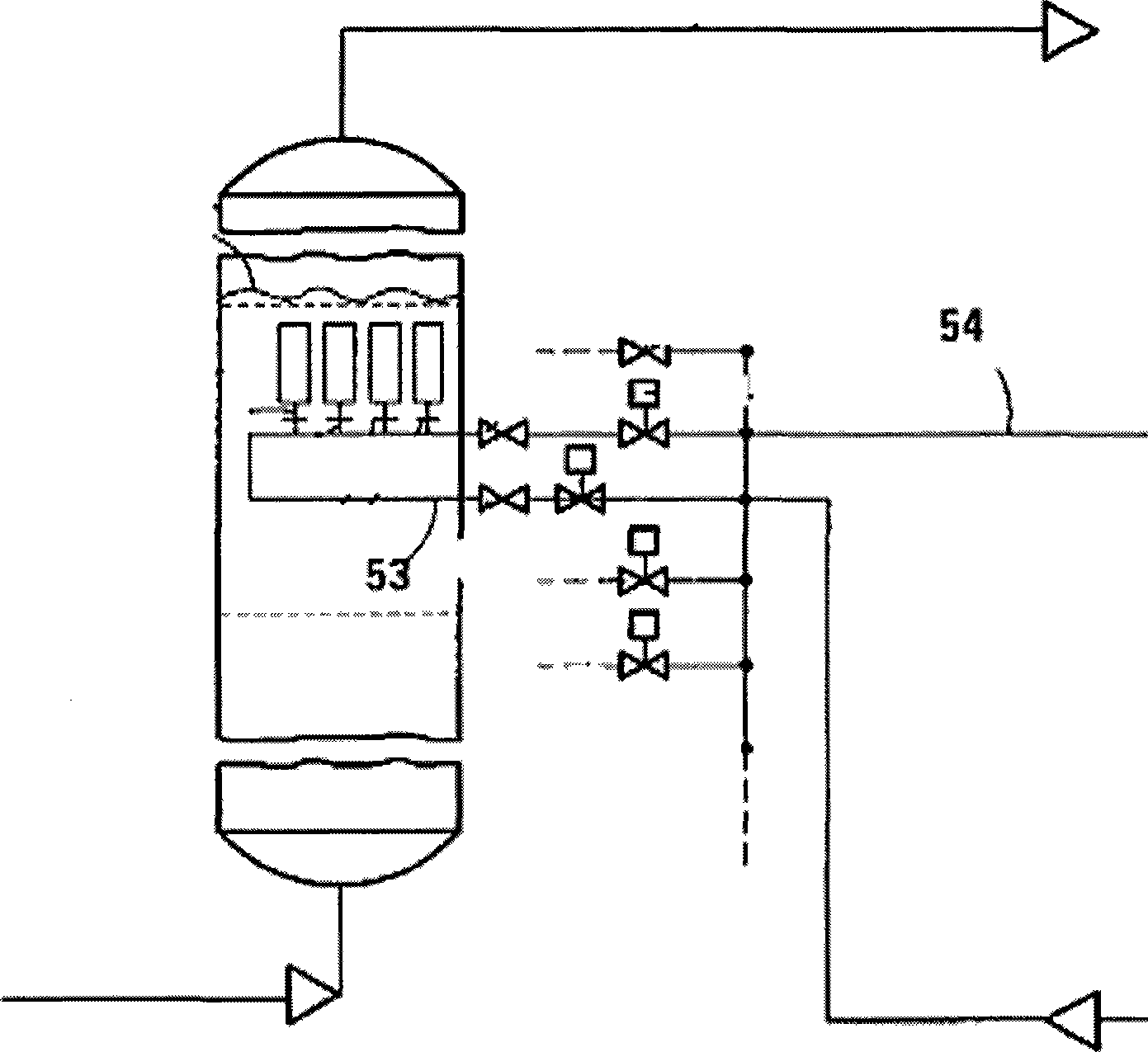

[0028] The device for fine filtration (secondary filtration) of the heavy fraction of the Fischer-Tropsch synthesis product is an automatic backwash filter system with a filtration precision of 0.2...

Embodiment 2

[0032] The Fischer-Tropsch synthesis Fe-based catalyst prepared by the method disclosed in CN1233463 was used for testing. In the slurry phase of the slurry bed reactor, the concentration of the catalyst is 30wt%, the particle size distribution range is 40-200μm, and the production capacity of the heavy fraction of the Fischer-Tropsch synthesis product is 30 tons / hour.

[0033] Such as figure 2 As shown, the SL50*800 asymmetric metal sintered filter rod 1 produced by Beijing Antai Technology Co., Ltd. is installed in the slurry bed reactor used. The filter rods are arranged in 35 groups, each group is composed of 10 parallel filter rods, and the filter rods are evenly arranged in the radial direction of the reactor. The filtration accuracy of the filter rod is 35 μm.

[0034] The device for performing fine filtration treatment (secondary filtration) on the heavy fraction of the Fischer-Tropsch synthesis product is an automatic backwash filter 2 with a filtration precision o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com