Low melting point lead-free solder alloy

A technology of lead-free solder alloy and low melting point, which is applied in the field of lead-free solder alloy and can solve problems such as poor reliability of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

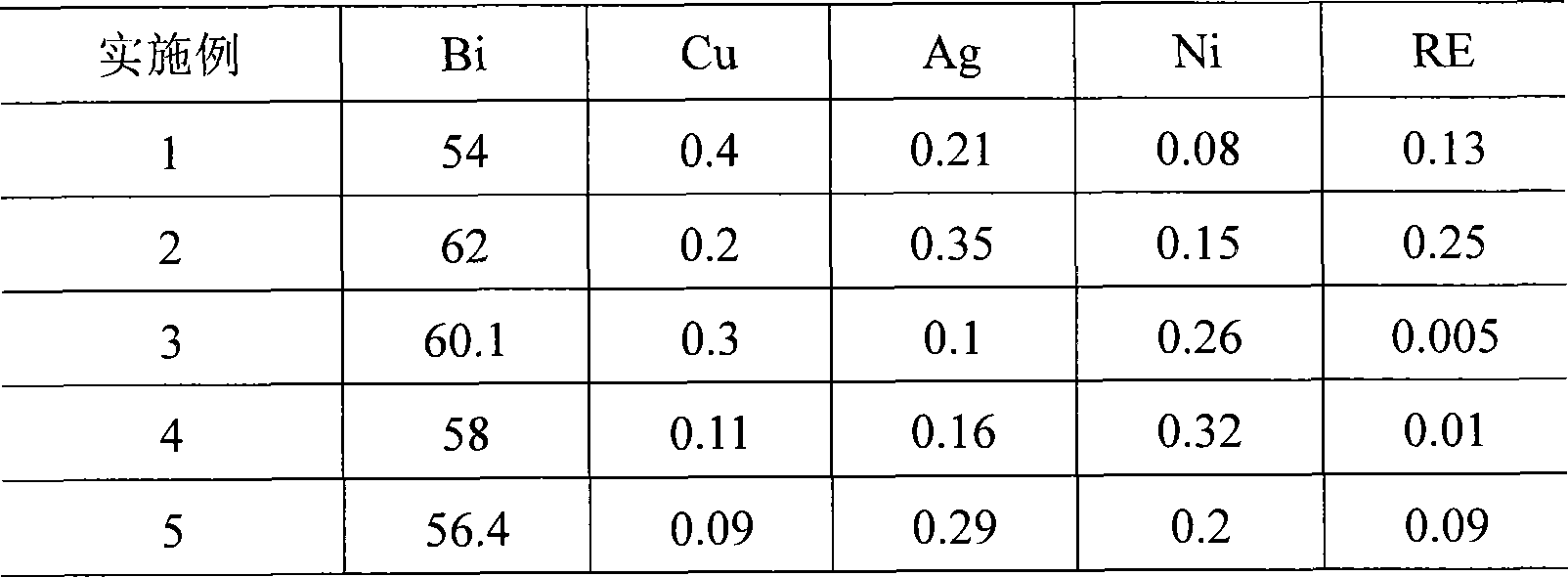

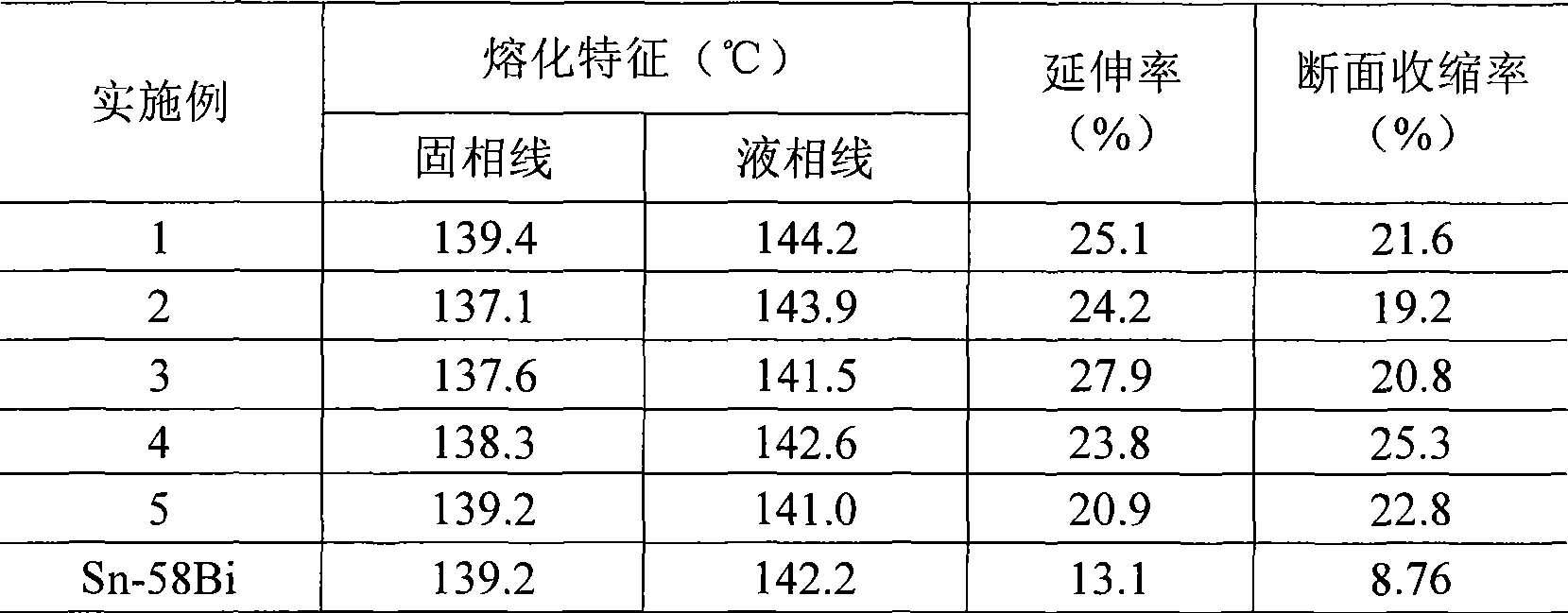

Examples

Embodiment Construction

[0011] In the preparation process of the alloy of the present invention, since the differences in melting points of Sn, Cu, RE, and Ni increase, and RE is easy to burn out, in order to accurately control the alloy composition and ensure the quality of the alloy, various alloys are added in the form of master alloys elements, prepared as follows:

[0012] Sn-Cu master alloy: Add 99.95% refined Sn into the graphite crucible, heat up after melting, and add 99.95% pure Cu to an appropriate temperature range. The mass percentage of refined Sn and pure Cu is prepared at a ratio of 90:10, stirred evenly, left standing, and cast into a Sn-Cu master alloy ingot with a Cu content of 10%.

[0013] Sn-RE master alloy: Add 99.95% refined Sn into the graphite crucible, heat up after melting, and add high-purity RE to an appropriate temperature range. The mass percentage of refined Sn and RE is prepared as 97:3, stirred evenly, left standing, and casted into a Sn-RE master alloy ingot with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com