DC motor speed control device and method

A technology of speed control device and DC motor, which is applied in the direction of excitation or armature current control, which can solve problems such as difficult installation, poor speed control performance, and complex structure, so as to save installation process steps and improve static performance and dynamic characteristics. , The effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

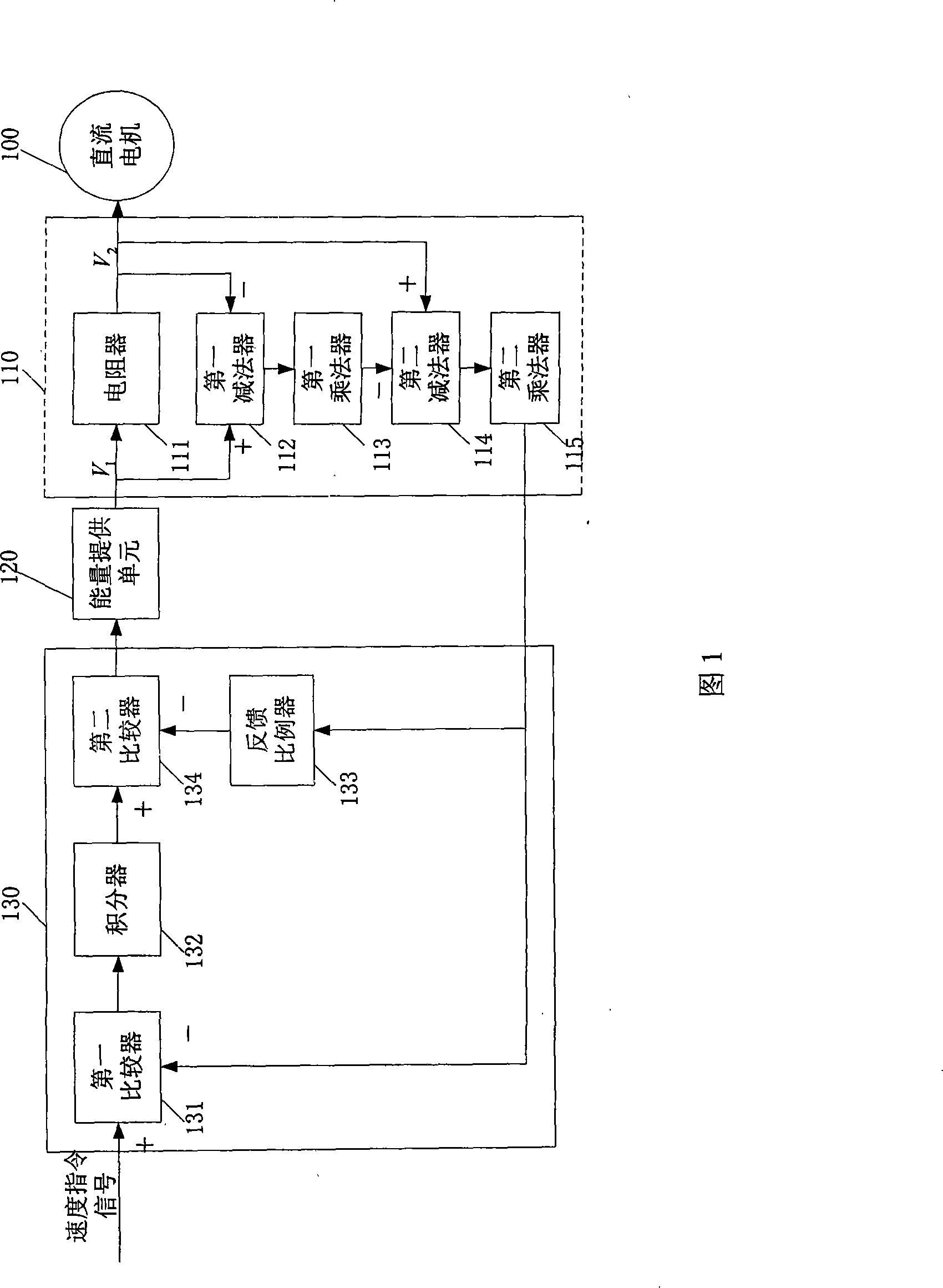

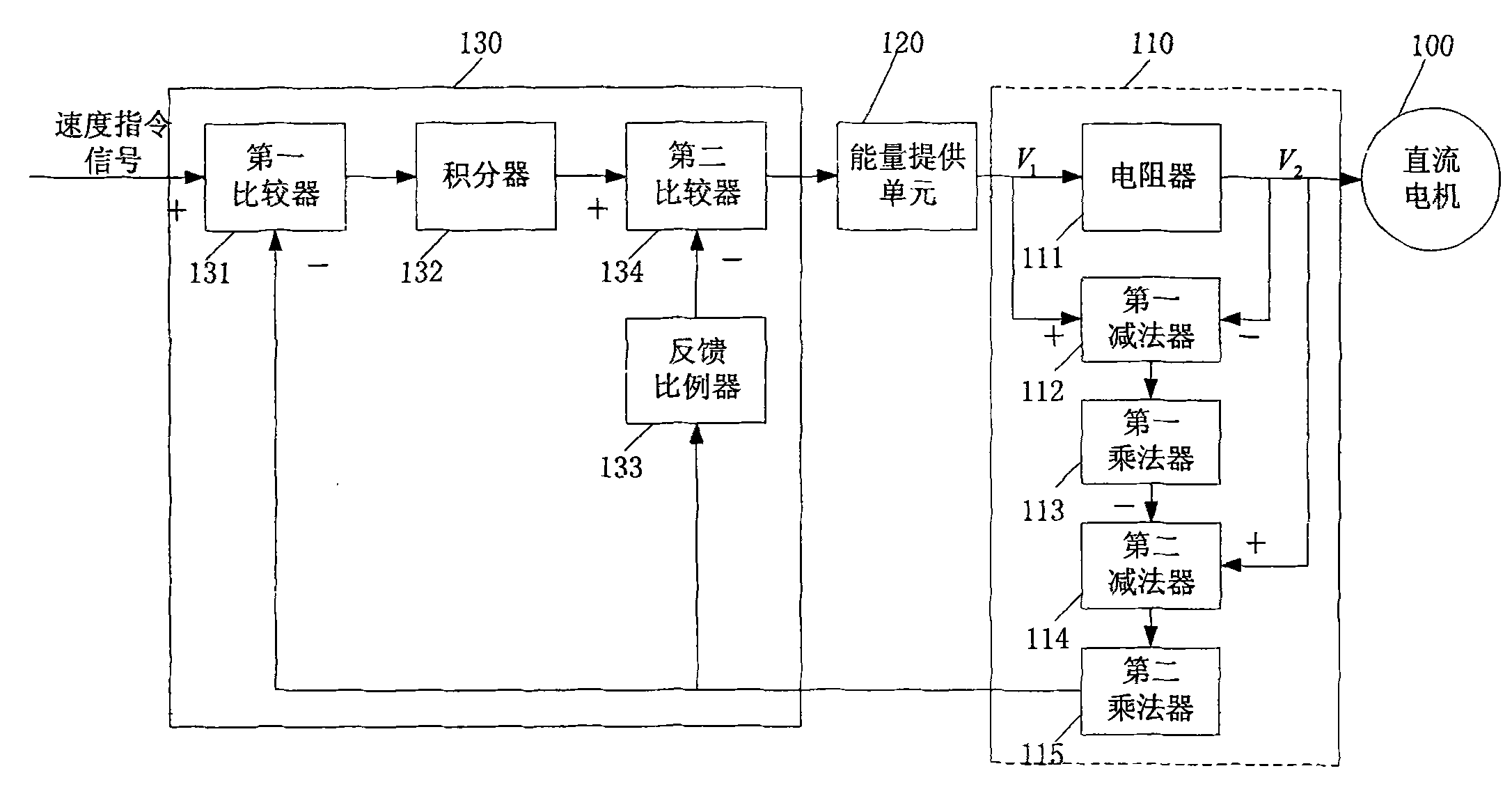

[0020] As shown in Figure 1, the speed determination unit 110 is connected in series in the armature circuit of the DC motor 100, the speed determination unit 110 is connected to the two ends of the resistor 111 by the first subtractor 112, and the resistor 111 is connected to the DC motor 100 , the output of the first subtractor 112 is sequentially connected to the first multiplier 113 , the second subtractor 114 and the second multiplier 115 . Wherein, the voltage signal at both ends of the resistor 111 can be obtained based on the current in the armature winding of the DC motor 100 . The first subtractor 112 is the voltage V across the resistor 111 1 and V 2 Subtract to get the voltage difference signal. The first multiplier 113 multiplies the voltage difference signal by a proportional coefficient, and the proportional coefficient of the multiplier is K a , proportional coefficient K a is determined based on the following formula:

[0021] K a = R m / R

[0022] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com