Surfacing method of alloy steel gear-wheel gear-ring transition layer

A technology of gear ring gear and alloy steel, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of poor weldability, high tendency of cold cracking, high carbon equivalent of alloy steel, etc., to achieve enhanced weldability, Avoid the effect of cold cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

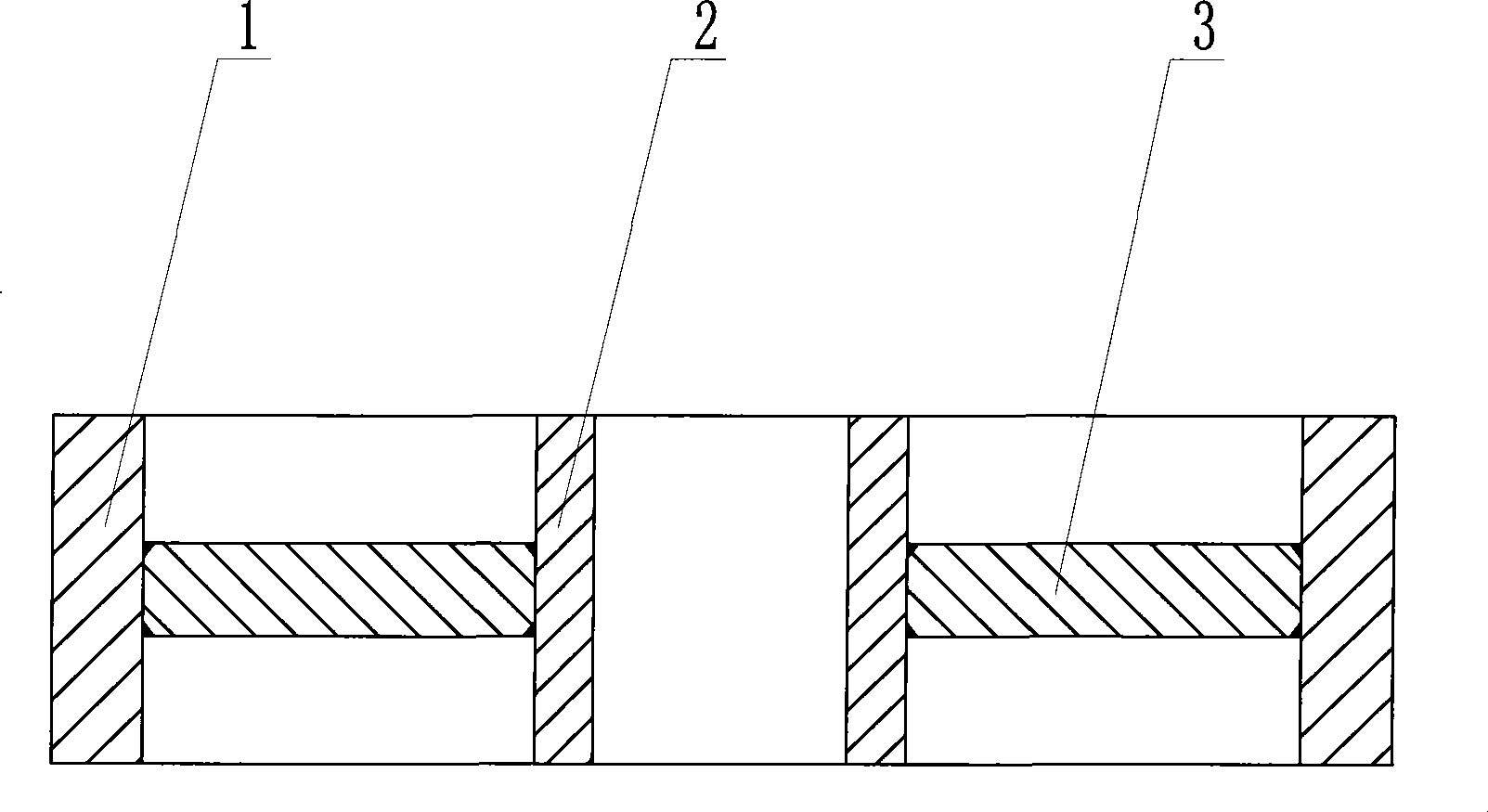

[0018] The surfacing welding method of the transition layer of the alloy steel gear ring gear of the present invention is to weld a transition layer on the alloy steel gear ring gear under high temperature conditions, and then weld the web plate to the transition layer when the temperature returns to normal , so that the alloy steel gear ring has good weldability, thereby avoiding cracks in the welding process, the present invention includes the following specific steps:

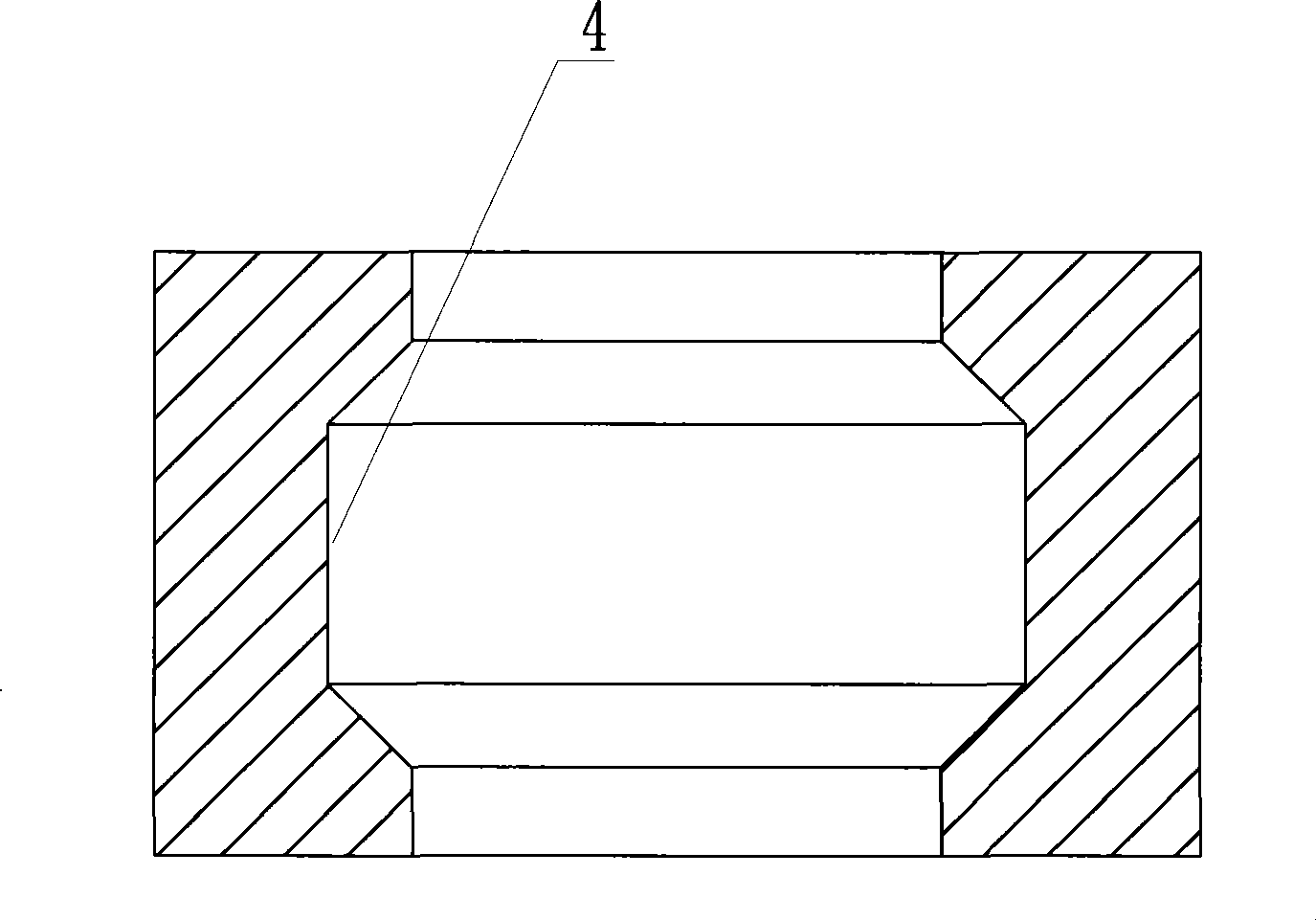

[0019] The first step is to process the transition layer groove: such as figure 2 As shown, the machining method is used to process the transition layer groove 4 in the alloy steel gear ring 1, and then the groove 4 is cleaned.

[0020] The second step, preheating and heat preservation: put the alloy steel gear ring into the far-infrared furnace for preheating, the preheating temperature is 325°C-375°C, and keep it warm for 4 hours.

[0021] The third step, surfacing transition layer: take the alloy steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com