Production technique of polymers coatings robber gloves for medical use

A polymer coating and rubber glove technology, applied in the field of gloves, can solve problems such as waste of energy and labor, backward technology, environmental pollution, etc., and achieve the effects of improving product performance, saving artificial energy, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

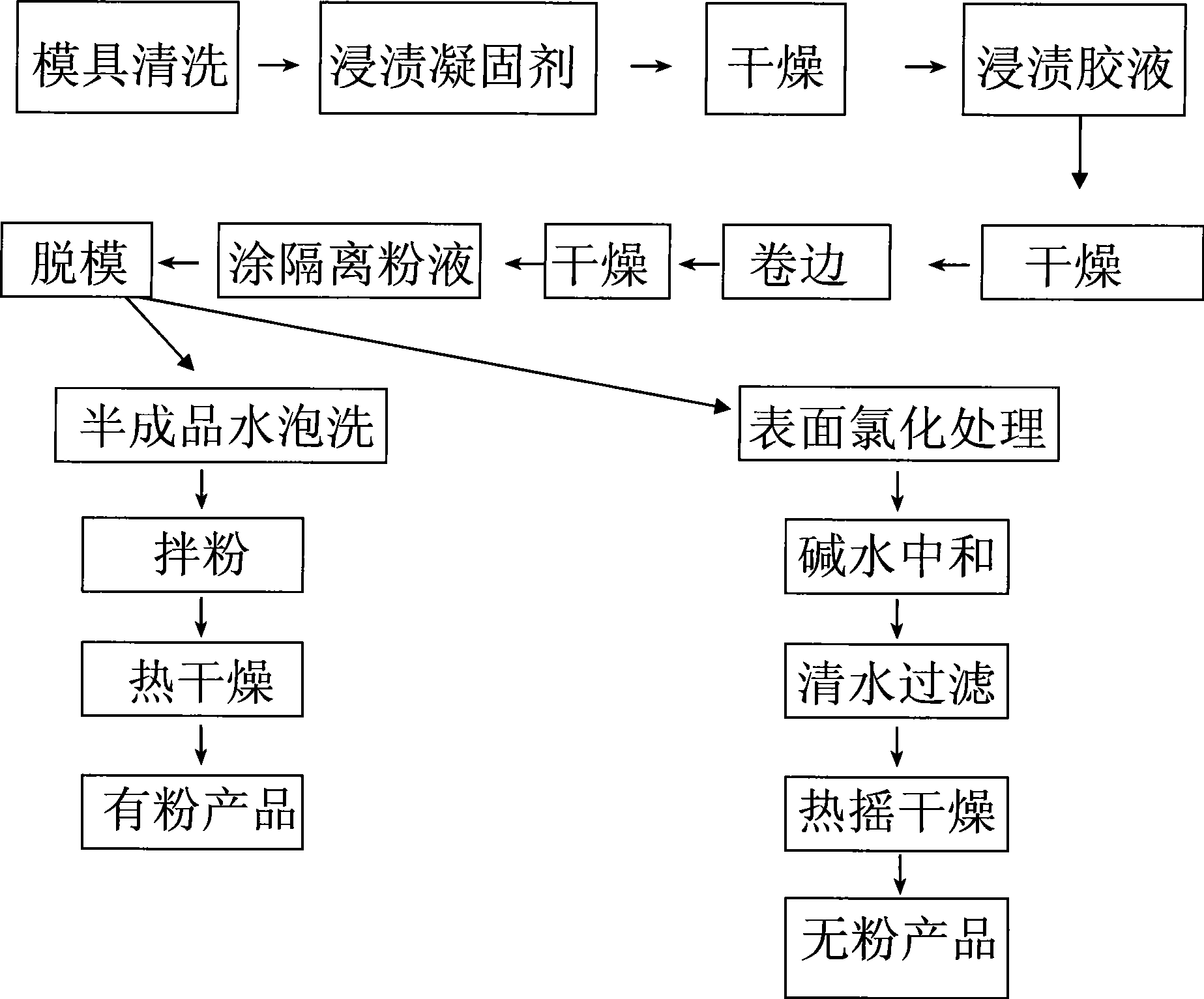

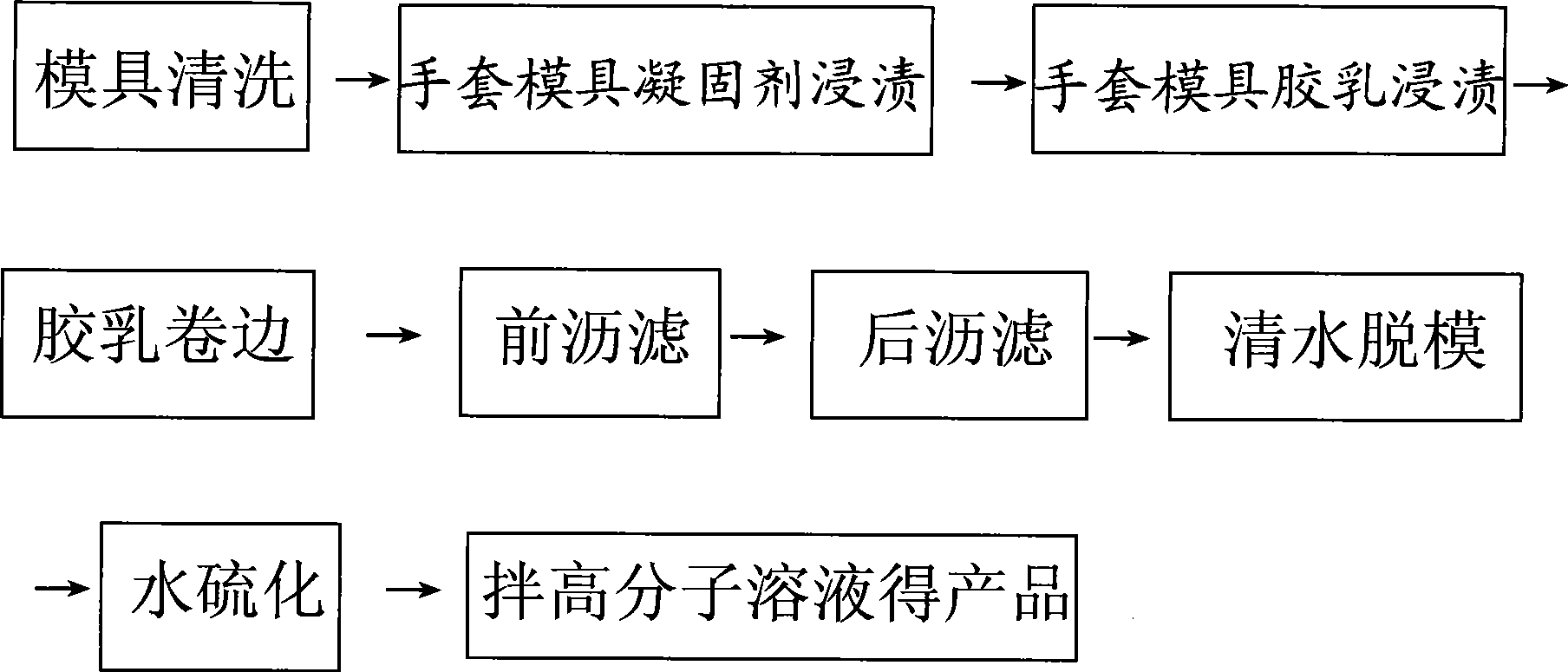

Method used

Image

Examples

Embodiment 1

[0015] A production process of polymer-coated medical rubber gloves, the production steps are: mold cleaning: dipping and pickling the glove mold with hydrochloric acid with a mass concentration of 5% for 10 seconds, and washing the glove mold after pickling with clean water at room temperature , and then rinsed with hot water at 80°C; glove mold coagulant dipping: after the mold is cleaned, it is immersed in a 55°C coagulant, and the time for the glove mold to be immersed in the coagulant is 1 minute; Drying under the same conditions for 3 minutes; dipping the glove mold latex: dip the glove mold dried in the previous step into latex, the latex temperature is 40°C, and the dipping time is 1 minute; after the glove mold is dipped in latex, dry it at 110°C for 3 minutes; Latex crimping: After the glove mold is dried in the previous step, the latex on the wrist part of the glove mold is crimped by the crimping device, and the crimping time is 8 seconds; pre-leaching: the glove mo...

Embodiment 2

[0017] A production process of polymer-coated medical rubber gloves, the production steps are: mold cleaning: use hydrochloric acid with a mass concentration of 5% to dip and pickle the glove mold for 12 seconds, and rinse the glove mold after pickling with clean water at room temperature , and then rinsed with hot water at 85°C; glove mold coagulant dipping: After the mold is cleaned, it is immersed in a 60°C coagulant, and the time for the glove mold to be immersed in the coagulant is 1.5 minutes; Drying under the same conditions for 4 minutes; dipping the glove mold latex: dip the glove mold dried in the previous step into latex, the latex temperature is 45°C, and the dipping time is 1.5 minutes; after the glove mold is dipped in latex, dry it at 115°C for 4 minutes; Latex crimping: After the glove mold is dried in the previous step, the latex on the wrist part of the glove mold is crimped by the crimping device, and the crimping time is 9 seconds; pre-leaching: the glove mo...

Embodiment 3

[0019] A production process of polymer-coated medical rubber gloves, the production steps are: mold cleaning: dipping and pickling the glove mold with hydrochloric acid with a mass concentration of 5% for 15 seconds, and washing the glove mold after pickling with clean water at room temperature , and then rinsed with hot water at 90°C; dipping the glove mold with coagulant: after the mold is cleaned, it is immersed in a 65°C coagulant, and the glove mold is dipped in the coagulant for 2 minutes; Drying under the same conditions for 5 minutes; dipping the glove mold latex: dip the glove mold dried in the previous step into latex, the latex temperature is 50°C, and the dipping time is 2 minutes; after the glove mold is dipped in latex, dry it at 120°C for 5 minutes; Latex crimping: After the glove mold is dried in the previous step, the latex on the wrist part of the glove mold is crimped by the crimping device, and the crimping time is 10 seconds; pre-leaching: the glove mold af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com