Temperature control device for on-board battery pack

A technology for temperature control devices and battery packs, applied in battery temperature control, temperature control without auxiliary power supply, battery/fuel cell control devices, etc., can solve the problems of poor fuel combustion efficiency and increased fuel consumption, and achieve The effect of increased heat transfer rate and rapid temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

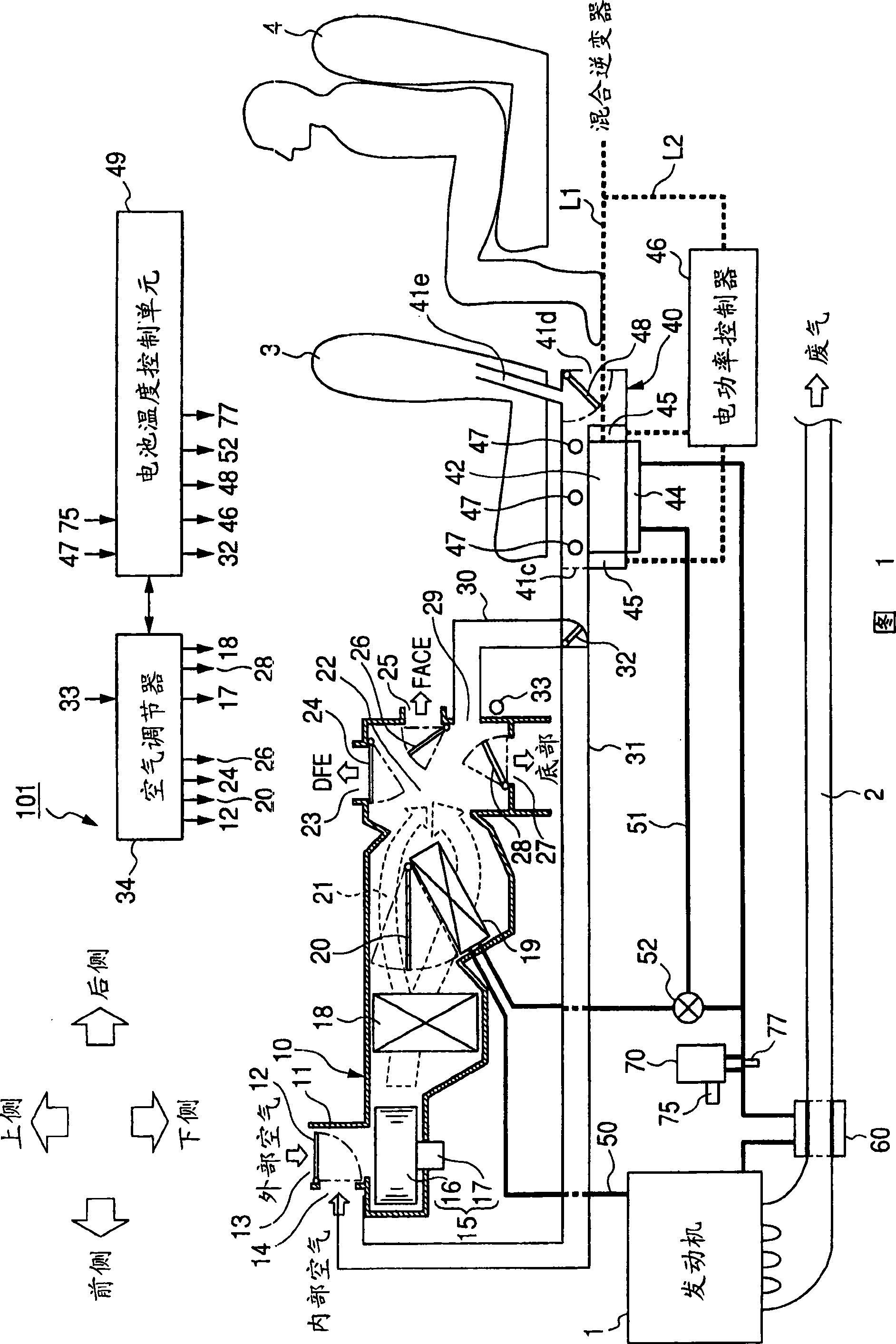

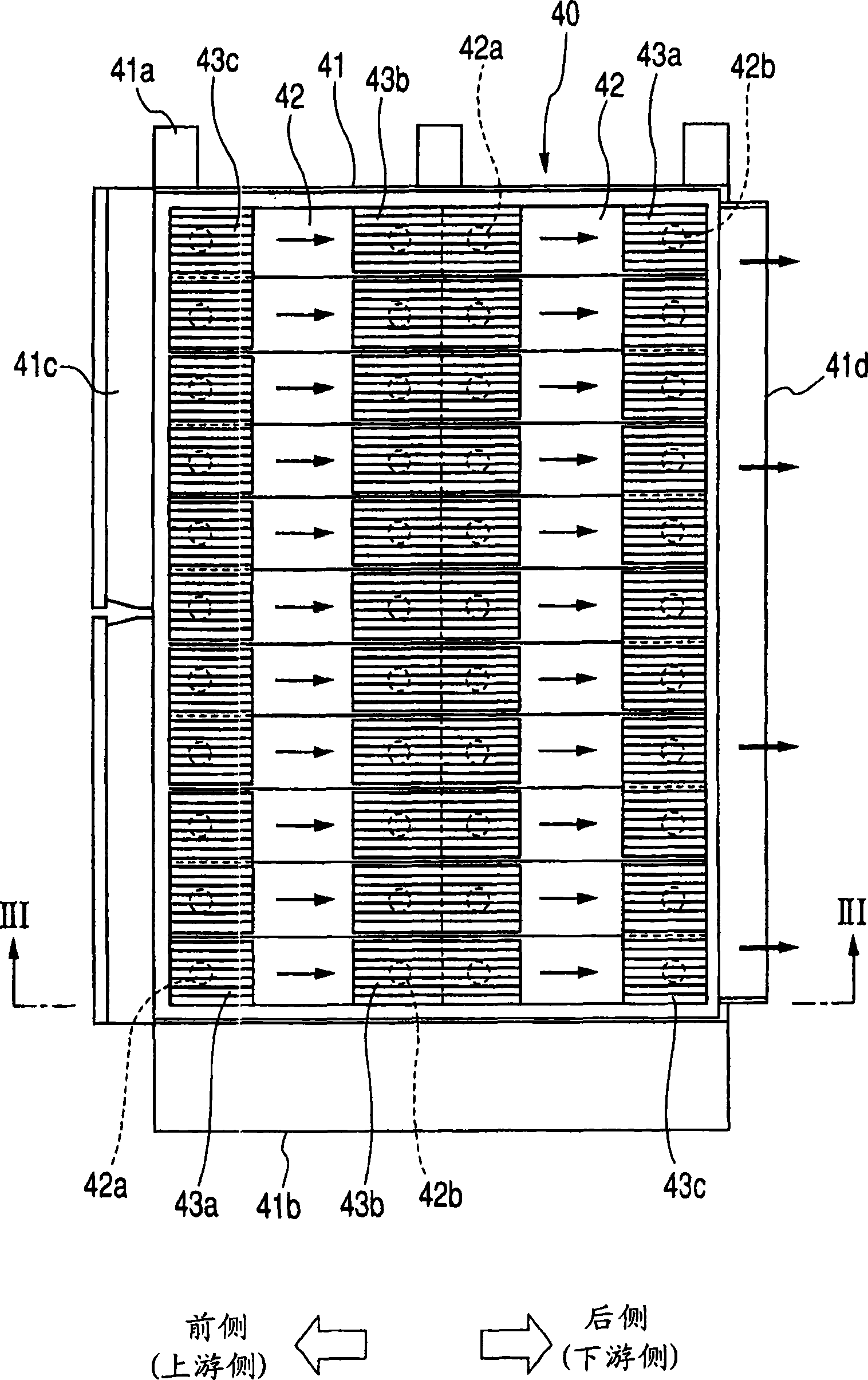

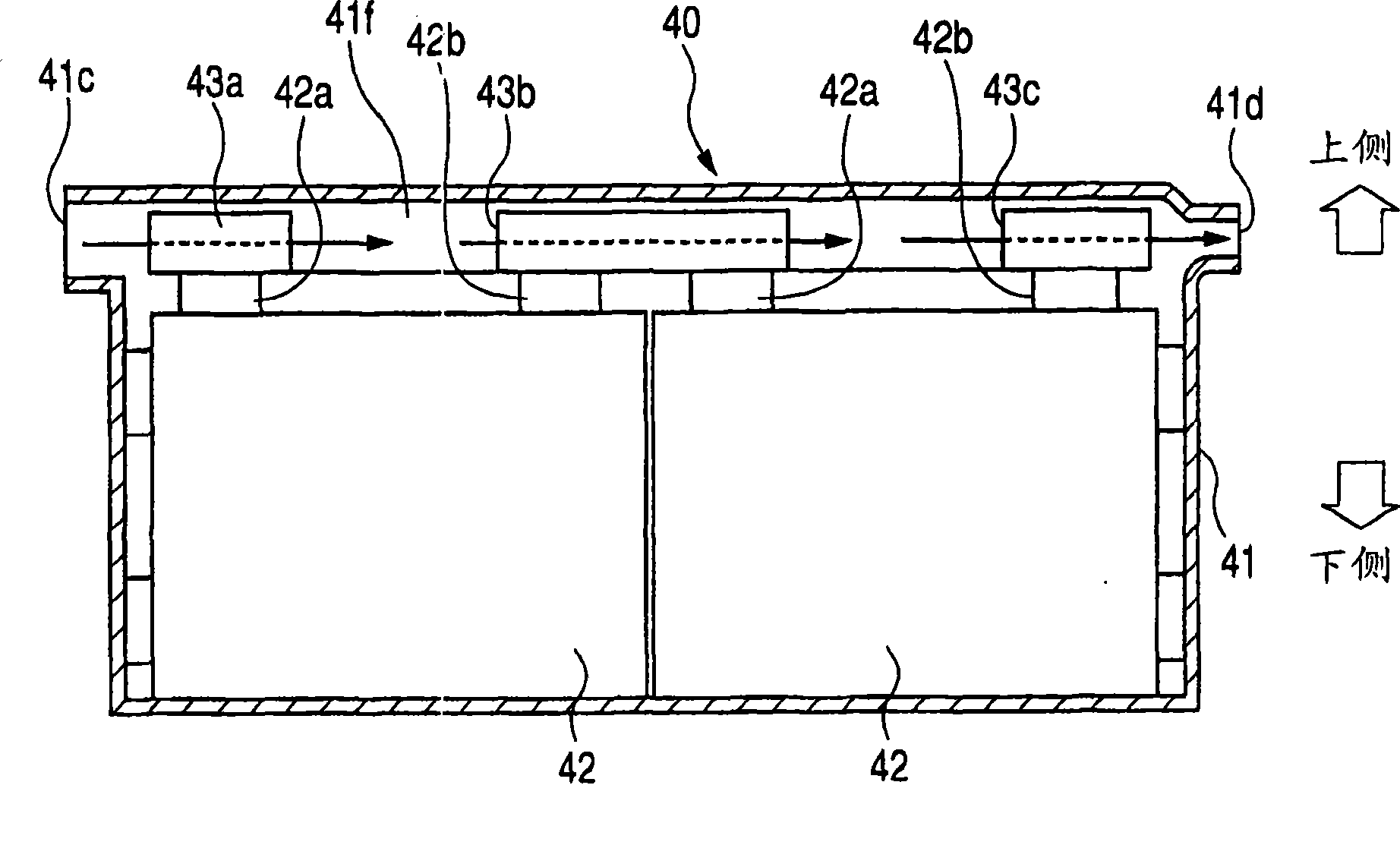

[0030] FIG. 1 is a schematic diagram of a temperature control device for an on-vehicle battery pack according to a first embodiment. The temperature control device 101 shown in FIG. 1 is mounted, for example, on a hybrid vehicle having a water-cooled internal combustion engine 1 and an electric motor (not shown) as a driving power source. The electric motor receives electric power from the on-board battery pack 40 to cooperate with the engine 1 to move the locomotive. The temperature control device 101 is used to heat the battery pack 40 or to cool the battery pack.

[0031] As shown in Figure 1, the temperature control device 101 has an air conditioner 10, an air duct (airduct) 30, and a hot water heater (or fluid heating element) 44, and the air conditioner 10 is used to adjust the temperature of the air to generate a temperature The controlled air blows a part of the controlled air to the compartment, and the remaining part of the controlled air is guided to the battery pa...

Embodiment 2

[0103] FIG. 7 is a schematic diagram of a temperature control device for the battery pack 40 according to the second embodiment.

[0104] As shown in FIG. 7 , the temperature control device 102 has a heat-cooling water circulation system different from that of the device 101 shown in FIG. 1 . Specifically, the circulation system of the control device 102 has a circulation channel 50, a first heat exchanger 60A, a heat storage tank 70, a fluid circulation channel 53 filled with brine, a fluid pump 54, a fluid temperature sensor 55, and a second heat exchanger 60B. , the circulation channel 50 communicates with the engine 1 and the heater core 19 . The first heat exchanger 60A is for recovering the heat of the exhaust gas of the engine 1 flowing through the exhaust pipe 2 and transferring the recovered heat to the cooling water of the channel 50 so that the hot cooling water circulates in the channel 50; the fluid pump 54 Operate under the control of the control unit 49 to circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com