Composite blending material for concrete and preparation method thereof

A composite admixture and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of difficult to adapt to the rapid growth of waste incineration fly ash, limited landfill disposal capacity, and high treatment costs. problems, to achieve the effect of being conducive to industrial production and popularization and application, good social and economic effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

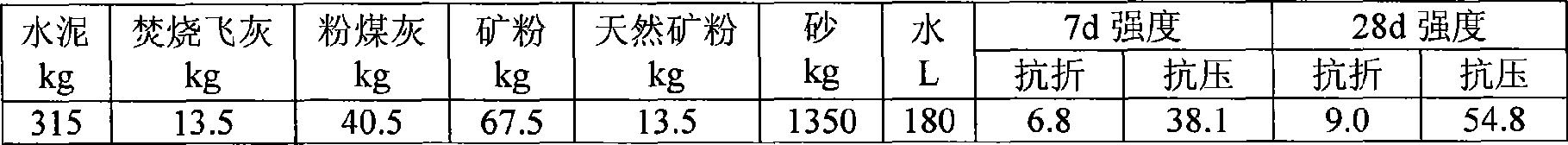

[0029] Embodiment 1: First, take by weighing 13.5kg incineration fly ash, 40.5kg of pulverized fly ash, 67.5kg of slag micropowder and 13.5kg of pulverized natural mineral powder according to the prescribed ratio, and put the above-mentioned batching materials into the mixer , After fully stirring and mixing uniformly, the composite admixture for concrete can be obtained.

[0030] The above-mentioned composite admixtures were formulated into cement mortar and tested for strength.

[0031] Take cement 315kg, the compound admixture 135kg that above-mentioned embodiment makes, total weight 450kg; The ratio between the cement in the cement mortar and the substitute cement composite admixture is 70:30;

[0032] In addition, weigh 1350kg of sand, so that the ratio of glue to sand in the cement mortar sand is glue: sand = 1:3.

[0033] After being prepared into cement mortar, that is, mortar, it is made into a block sample for strength test.

[0034] The ratio of cement mortar and ...

Embodiment 2

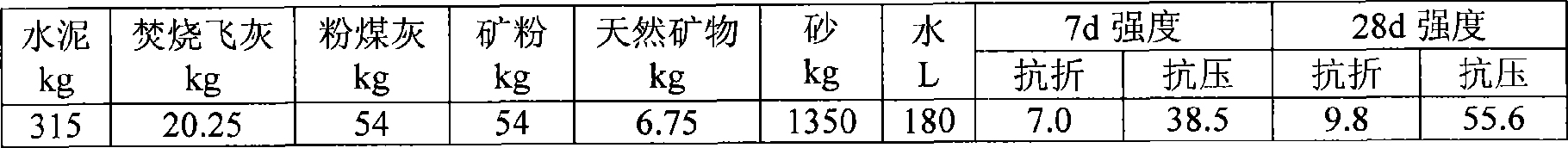

[0037] Embodiment two: first take by weighing 20.25kg incineration fly ash, pulverized fly ash 54kg, slag micropowder 54kg and pulverized natural mineral powder 6.75kg by the proportioning of regulation, above-mentioned batching material is put into mixer, through After fully stirring and mixing uniformly, the composite admixture for concrete can be obtained.

[0038] The above-mentioned composite admixtures were formulated into cement mortar and tested for strength.

[0039] Take cement 315kg, the compound admixture 135kg that above-mentioned embodiment makes, total weight 450kg; The ratio between the cement in the cement mortar and the substitute cement composite admixture is 70:30;

[0040] In addition, weigh 1350kg of sand, so that the ratio of glue to sand in the cement mortar sand is glue: sand = 1:3.

[0041] After being prepared into cement mortar, that is, mortar, it is made into a block sample for strength test.

[0042] The ratio of cement mortar and strength test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com