Electric driving fully variable valve actuator for air-powered engine

A pneumatic engine, electric drive technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem that the rotary valve intake device of pneumatic engine cannot be realized, reduce throttling loss, overcome high opening and closing frequency , the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

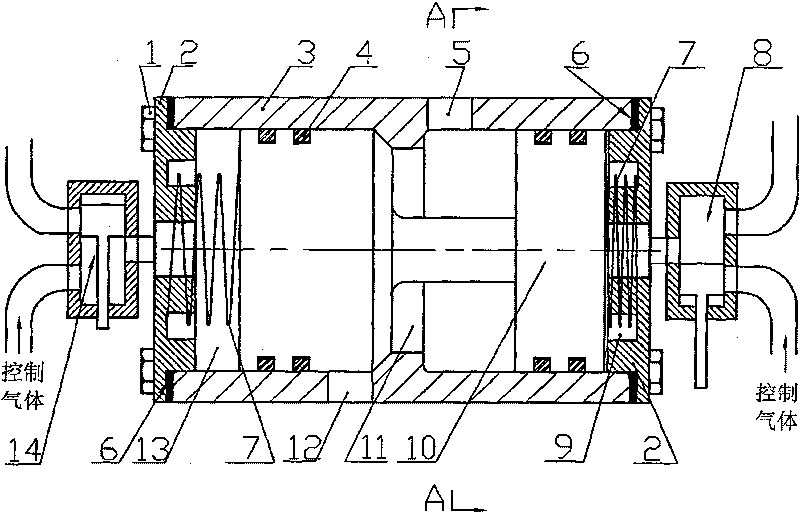

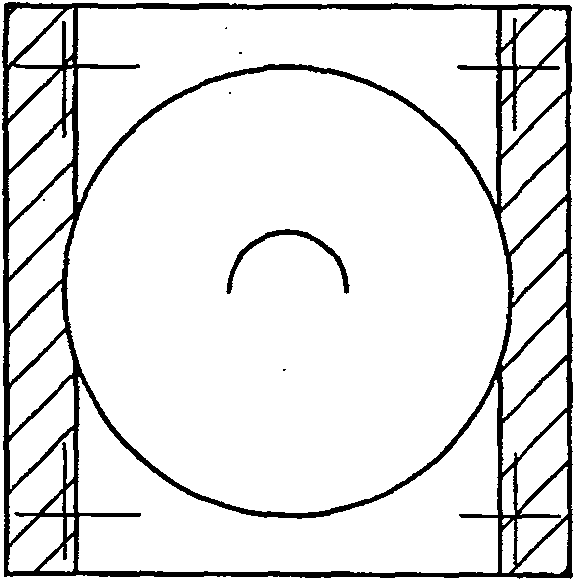

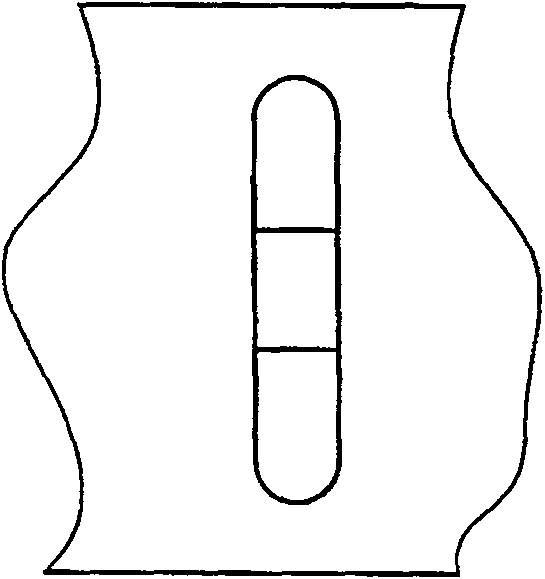

[0021] In this embodiment, the electric drive of the pneumatic engine fully variable valve mechanism is as follows: figure 1 As shown, on both sides of the cuboid-shaped valve body 3, there are narrow and long waist-shaped hole-shaped air inlets 5 and air outlets 12; the valve core 10 is installed in the inner cavity of the valve body 3 and can move back and forth left and right, with two cylinders The two ends of the valve core 10 divide the inside of the valve body 3 into three chambers, the left chamber 13, the middle chamber 11 and the right chamber 9. Several sealing rings 4 are installed on the two ends of the valve core 10 to complete the sealing between the left chamber 13 and the middle chamber 11 and the right chamber 9 and the middle chamber 11; the inner wall of the valve body 3 is in the middle There is an annular boss at the position of the chamber 11;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com