Organic thin-film transistor and method for controlling surface energy of polymer material layer

A technology of polymer materials and organic thin films, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems that plastic substrates cannot withstand high temperatures and are not suitable for plastic substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

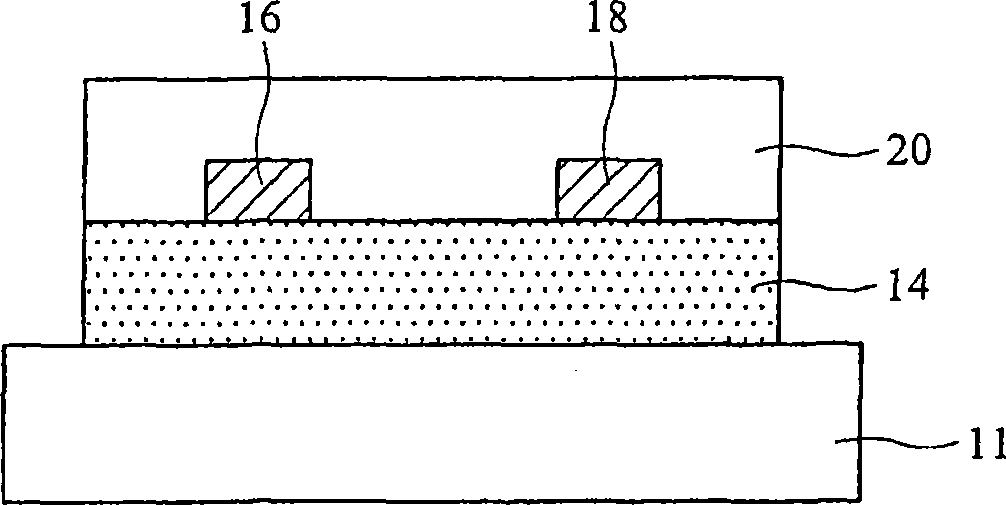

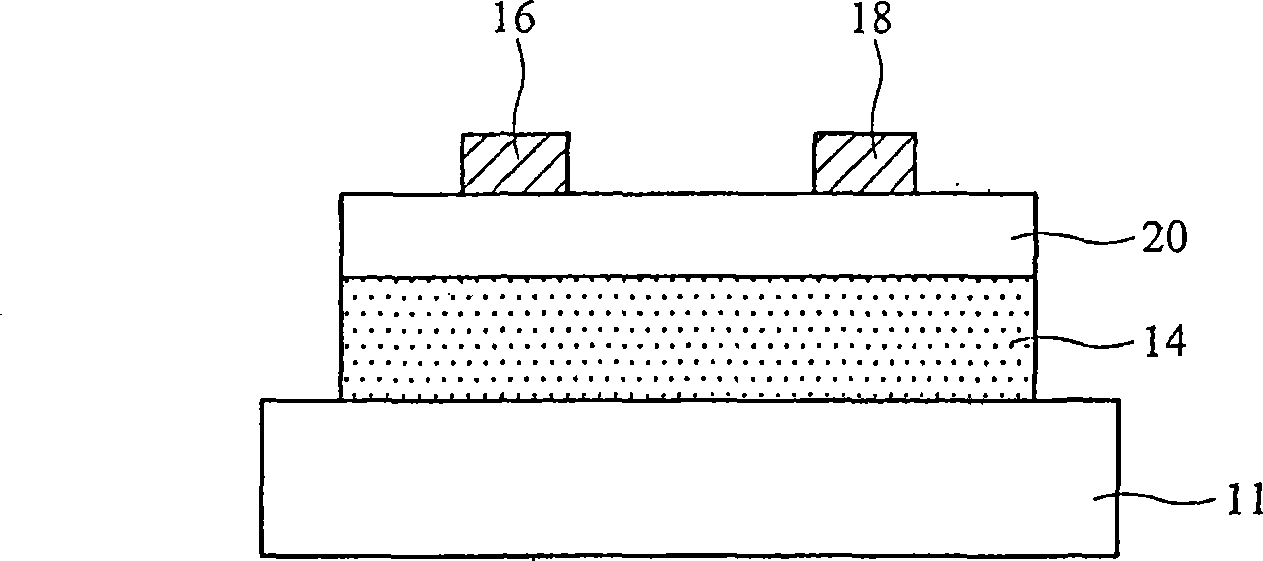

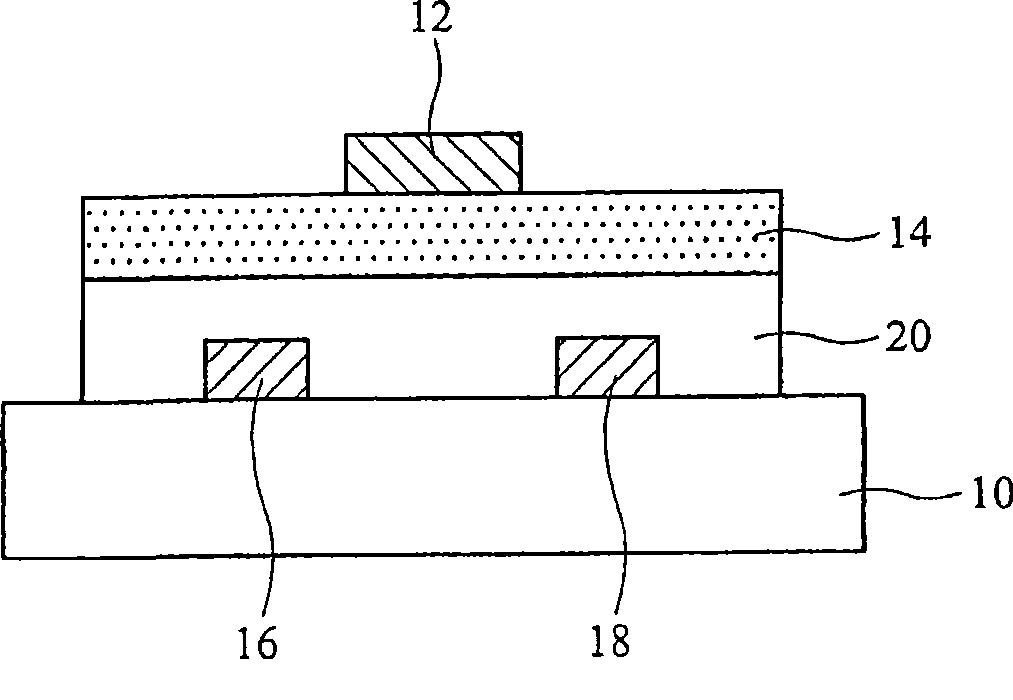

Image

Examples

Embodiment 1~2

[0059] The composition of the dielectric layer material formula solution is: 10wt% PVP+5wt%PMF+3wt%PAG+82wt%PGMEA

[0060] Get polymer PVP (molecular weight Mw is 20000, produced by Aldrich company) 0.1g, crosslinking agent PMF (molecular weight Mw is 500, produced by Aldrich company) 0.05g and photoacid generator (PAG) (4-[(2-hydroxy deca Tetraalkyl) oxygen] phenyl) phenyliodonium-hexafluoroantimonate ((4-[(2-Hydroxytetradecyl)oxy]phenyl)phenyliodonium hexafluoroantimomnate) 0.03g (produced by Aldrich Company), use PGMEA (produced by Tedia Company) As a solvent, it is prepared into a formula solution containing 10wt% PVP, 5wt% PMF and 3wt% PAG.

[0061] Film preparation: after filtering the above formulation solution with a 0.2 μm filter, the solution was coated on a silicon wafer (wafer) by spin coating (rotation speed 1000 rpm, time 30 sec). After the coated film was irradiated with 365nm UV light for 1 minute, the film of Example 1 was baked at 100°C for 5 minutes, and th...

Embodiment 3~7

[0070] The composition of the dielectric layer material formula solution is: 11wt% PVP+4wt%PMF+2wt%PAG+83wt%PGMEA

[0071] Get the polymer PVP0.11g identical with embodiment 1, cross-linking agent PMF0.04g and photoacid generator (PAG) 0.03g, use PGMEA as solvent and be formulated into containing 11wt%PVP, 4wt%PMF and 2wt%PAG Formula solution. A thin film was prepared in the same manner as in Example 1, and irradiated with 254nm UV light for 10 minutes. The baking temperature / time and PGMEA test results are listed in Table 2.

[0072] Surface energy test: The surface energy of the films of Examples 3 to 7 was measured by contact angle measurement (using a FACE contact angle meter, Kyowa Kaimenkagaku Co.), using distilled water and diiodomethane CH 2 I 2 (di-iodomethane) is used as a detection liquid, and the surface energy is calculated by measuring the contact angle of distilled water and diiodomethane on the film surface.

[0073] The PGMEA test and the surface energy tes...

Embodiment 8~10

[0078] The materials used in Examples 8-10 are the same as those in Example 1, and the composition of its formulation solution is listed in Table 3 below. The formulation solution of Examples 8-10 is made into a film in the same film preparation mode as in Example 1. The baking temperature is 120° C., and the baking time is 30 minutes. Next, the films of Examples 8-10 were subjected to PGMEA test and surface energy test, and the results are listed in Table 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com