Improving disinfection efficacy of lens care regimen for rigid gas permeable contact lenses

A breathable, lens technology, applied in chemical instruments and methods, detergent compositions, chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

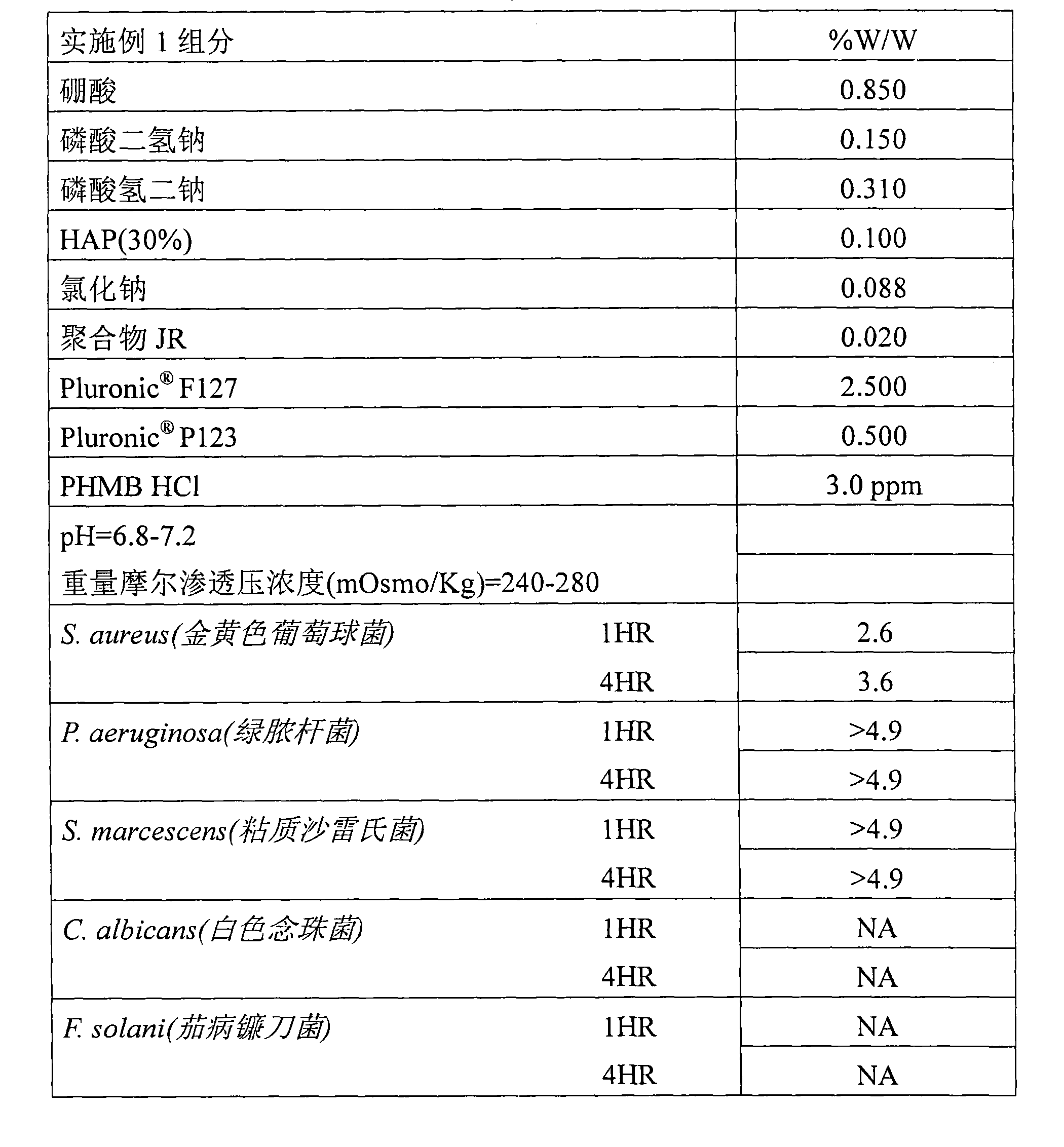

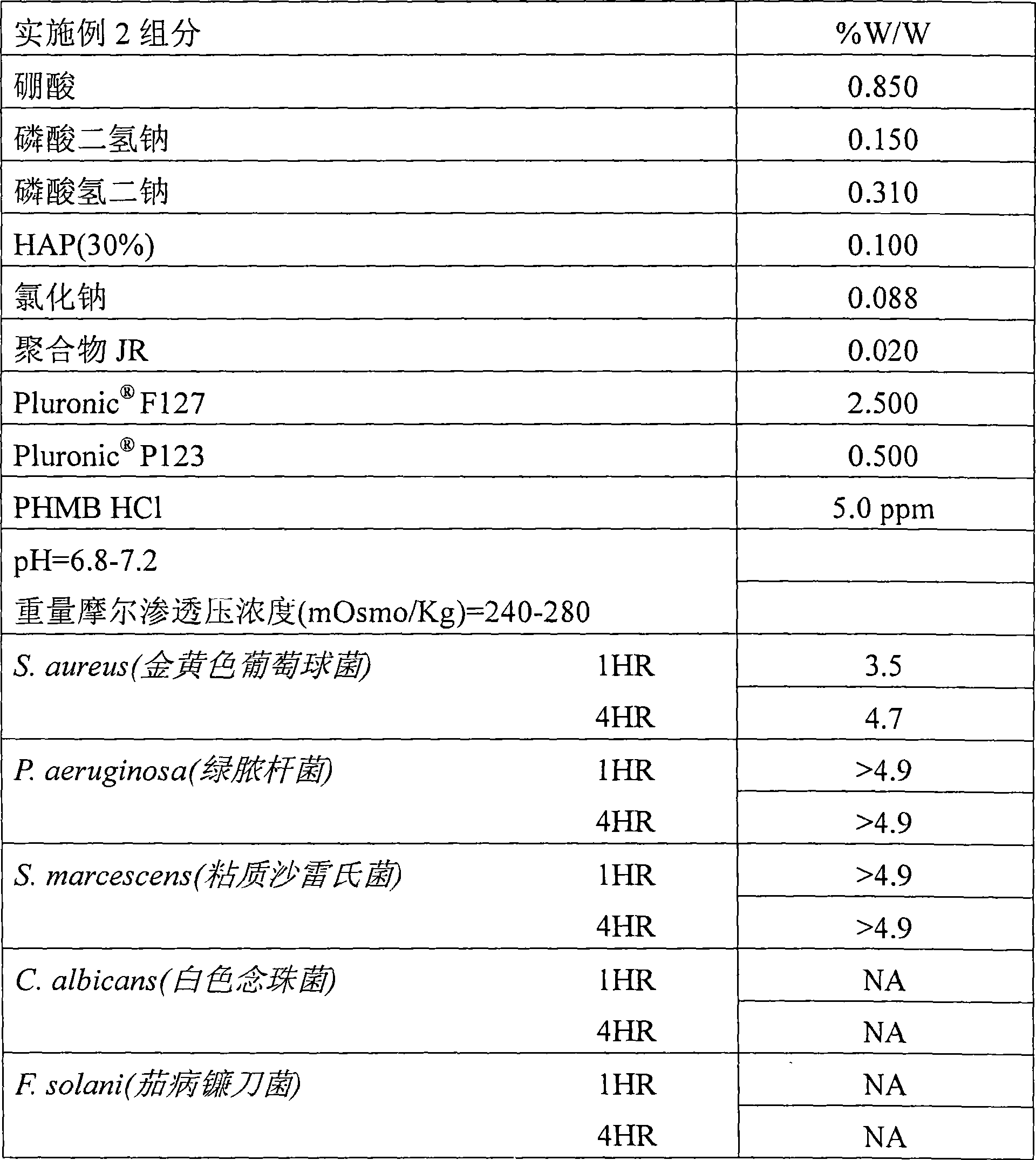

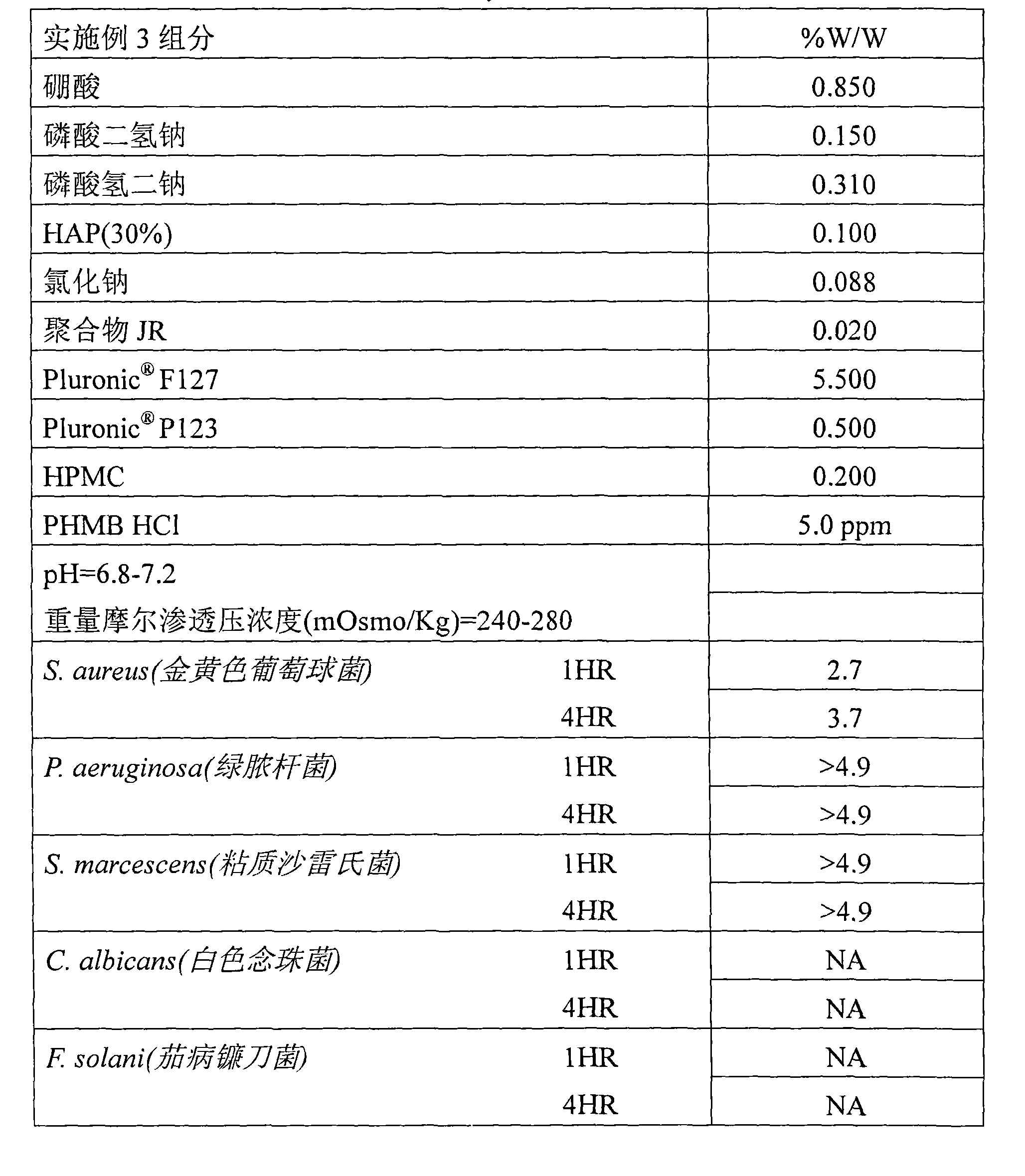

[0061] Examples 1-14 contain PHMB HCl and Composition of P123 biocidal individual test

[0062] Evaluation by Antimicrobial efficacy of solutions prepared with P123 and PHMB HCl for chemical disinfection of contact lenses using 10% organic contaminants. The solution components are listed in Tables 1 to 14 below.

[0063] Microbial challenge inoculum prepared with Pseudomonas aeruginosa (ATCC 9027), Staphylococcus aureus (ATCC 6538), Serratia marcescens (ATCC 13880), Candida albicans (ATCC 10231) and Fusarium solani (ATCC 36031) . Grow test organisms on appropriate agar and harvest the culture using sterile Dulbecco's Phosphate Buffered Saline plus 0.05% w / v Polysorbate 80 (DPBST) or a suitable diluent and transfer to a suitable container middle. The spore suspension was filtered through sterile glass wool to remove mycelial fragments. As appropriate, filter S. marcescens through a 1.2 micron filter to clarify the suspension. After harvesting, the suspension was cen...

Embodiment 15-32

[0097] Embodiment 15-32 adopts PHMB HCl: Alexidine 2HCl and Combination of P123 single test for biocidal

[0098] Experiments were carried out to investigate the use of Microbial killing effect of solutions prepared with P123 and a combination of PHMB HCl and alexidine 2HCl on 10%, 50% and 100% organic pollutants. The test solutions are identified in Tables 15-32 below. The antimicrobial efficacy of each chemical used to disinfect contact lenses was evaluated according to the methods outlined in Examples 1-14.

[0099] Microbial reductions using 10% organic pollutants are calculated at specific time points and recorded in the records listed below in Tables 15-28. Microbial reductions using 100% organic pollutants were calculated at specific time points and recorded in the records listed in Tables 29-30 below. Microbial reductions using 50% organic pollutants were calculated at specific time points and recorded in the records listed in Tables 31 to 32 below.

[010...

Embodiment 33

[0136] Example 33 - Preparation of Formulations

[0137] Table 33 lists the components of the base formulations used in the examples.

[0138] Table 33: Base formulations

[0139]

[0140] Table 34 lists the actual surfactant concentrations for Formulations I-IV. All formulations were prepared by mixing respective amounts of base formulation, surfactant and water. The formulation is then filtered.

[0141] Table 34: Composition of Formulations I-IV

[0142]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com