Rotary tillage broadcast sowing combined drill for wheat

A seeder, wheat technology, applied in seeder parts, fertilizers and seeding equipment, agricultural machinery and implements, etc., can solve the problems of drought death, low operation efficiency, inability to guarantee effective seeding rate and germination rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

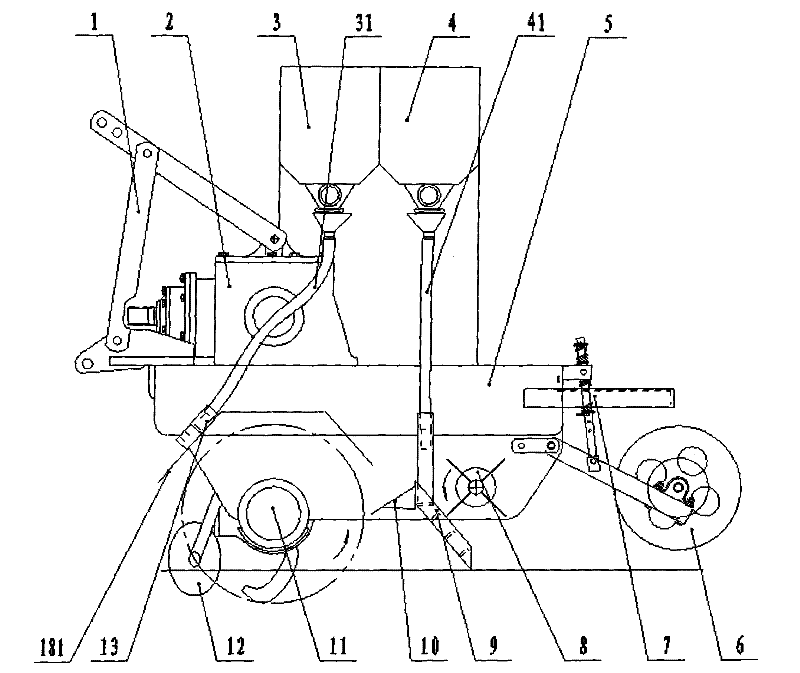

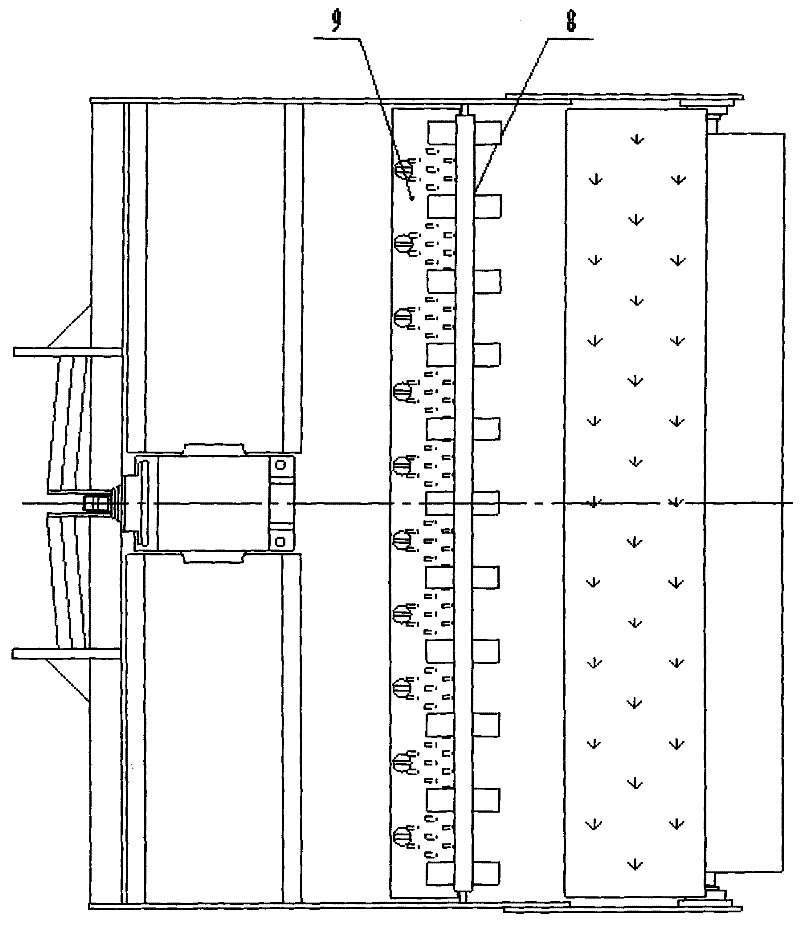

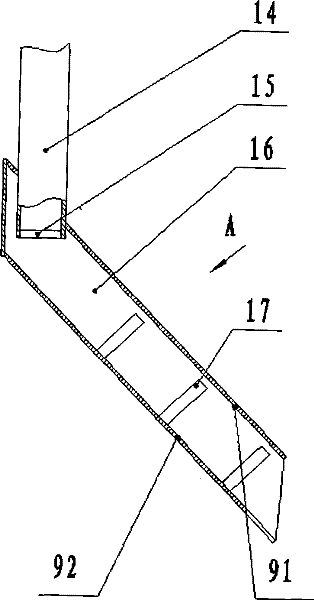

[0013] see Figure 1 to Figure 5 : this wheat rotary tillage sowing united seeder comprises frame 5 and suspension frame 1, gear box 2, rotary tillage mechanism 11, seeding device 4 (containing seed box and seeding device and transmission mechanism, with prior art) and Its seed delivery pipe 41, and seed delivery pipe 41 has 4, and lateral interval is arranged, and below seed delivery pipe 41 all is connected with soil layer lower seed lateral even spreading device 9 (connected at the lower end of drop seed pipe 14), soil layer The lower seed horizontal spreading device 9 is located at the back of the cutter shaft of the rotary tillage mechanism 11. The structure of the seed horizontal uniform spreading device 9 under the soil layer is as follows: a box-type seed horizontal uniform dispersion cover 91 is provided. Sub-rod 15 (can be shapes such as cylinder or prism shape), the seed outlet of box-type seed laterally evenly scattered outer cover 91 lower ends is positioned at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com