Semi-sandwich alum-chromium olefin polymerizing catalyst, preparation and uses thereof

A polymerization catalyst, core chromocene olefin technology, applied in the field of semi-sandwich chromocene olefin polymerization catalyst and its preparation, can solve the problems of high production cost and easy poisoning, and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

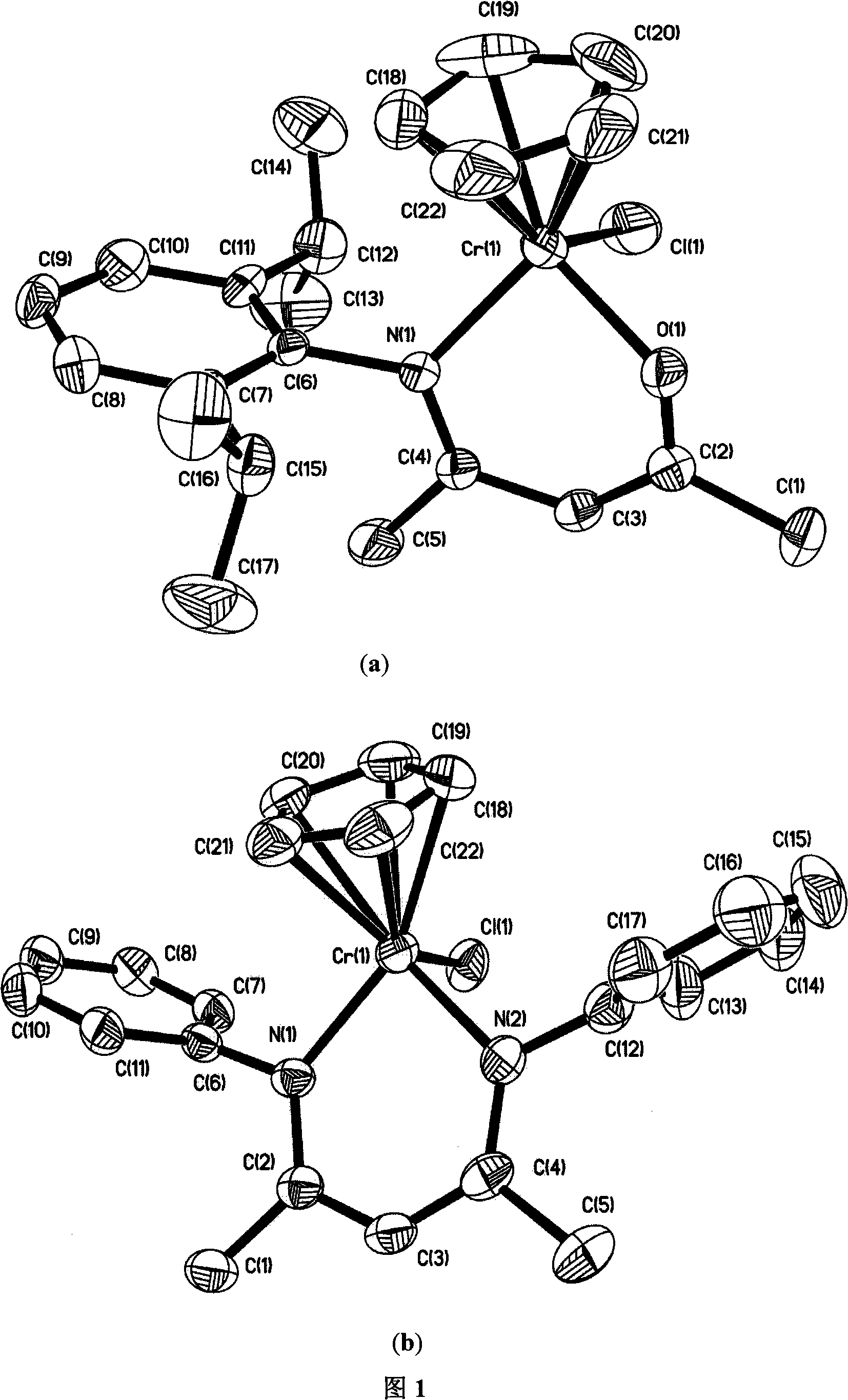

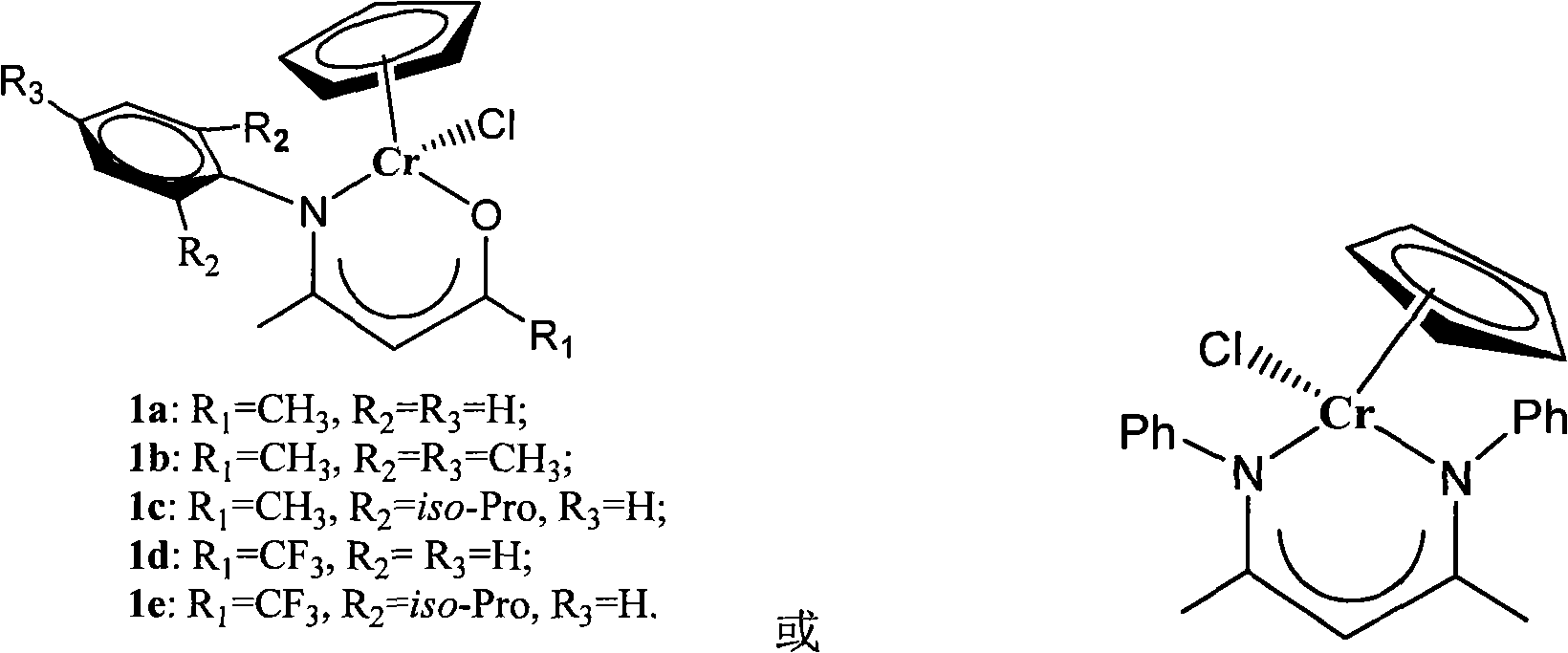

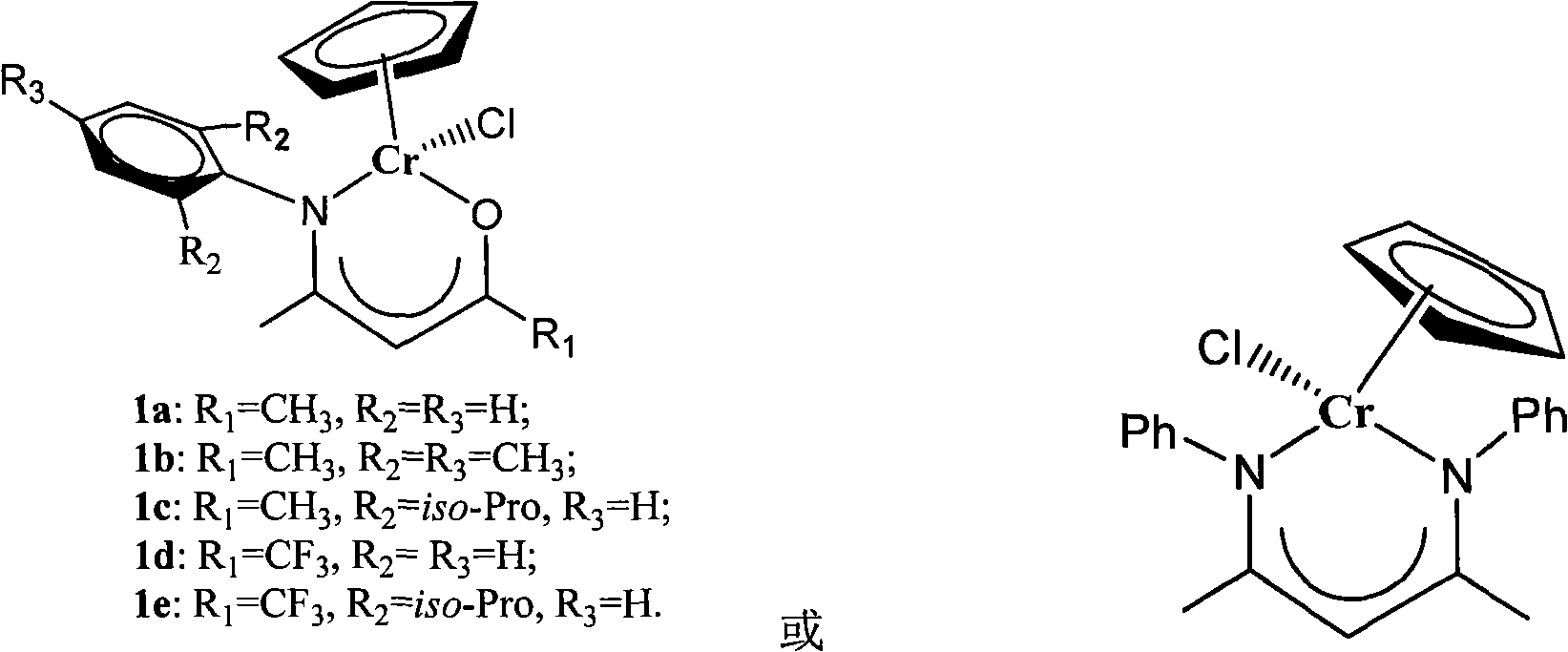

[0018] Embodiment 1: the preparation of semi-sandwich chromocene olefin polymerization catalyst 1a:

[0019] Under the protection of anhydrous, oxygen-free and nitrogen, add 0.10 mmol of n-butyllithium to the tetrahydrofuran or toluene solution containing 0.10 mmol of β-monoketimine ligand L1 at -78 ° C, and gradually raise to room temperature , and stirred for 6 hours. At -78°C, the obtained lithium salt was transferred to 0.10 mmol of dichlorocyclopentadiene chromium tetrahydrofuran tetrahydrofuran solution (the ratio of the amount of the two substances was 1:1), and after stirring at room temperature for 12 hours, the Dry solvent, add 10ml of dichloromethane, centrifugal filter to remove inorganic salts, concentrate the filtrate to 3ml, add 10ml of n-hexane, freeze at low temperature, precipitate crystals, filter, wash with n-hexane, and vacuum dry to obtain the corresponding blue-green semi-sandwich chromocene olefin Polymerization Catalyst 1a. Yield 48%.

[0020] Eleme...

Embodiment 2

[0021] Embodiment 2: the preparation of semi-sandwich chromocene olefin polymerization catalyst 1b:

[0022] Under the protection of anhydrous, oxygen-free and nitrogen, add 0.34mmol of n-butyllithium to the tetrahydrofuran or toluene solution containing 0.34mmol of β-monoketimine ligand L2 at -78°C, and gradually raise to room temperature , and stirred for 6 hours. At -78°C, the obtained lithium salt was transferred to a tetrahydrofuran solution of 0.34 mmol dichlorocyclopentadiene chromium tetrahydrofuran (the ratio of the amount of the two substances was 1:1), and after stirring at room temperature for 12 hours, Drain the solvent, add 15ml of dichloromethane, remove inorganic salts by centrifugal filtration, concentrate the filtrate to 5ml, add 20ml of n-hexane, freeze at low temperature, precipitate crystals, filter, wash with n-hexane, and dry in vacuum to obtain the corresponding blue-green semi-sandwich chromocene Olefin Polymerization Catalyst 1b. Yield 46%.

[0023...

Embodiment 3

[0024] Embodiment 3: the preparation of semi-sandwich chromocene olefin polymerization catalyst 1c:

[0025] Under the protection of anhydrous, oxygen-free and nitrogen, add 10mmol of n-butyllithium to the tetrahydrofuran or toluene solution containing 10mmol of β-monoketimine ligand L3 at -78°C, gradually rise to room temperature, and stir 6 hours. At -78°C, the obtained lithium salt was transferred to a tetrahydrofuran solution of 10 mmol of dichlorocyclopentadiene chromium tetrahydrofuran (the ratio of the amount of the two substances was 1:1), and after stirring at room temperature for 12 hours, the Dry solvent, add 20ml of dichloromethane, centrifugal filter to remove inorganic salts, concentrate the filtrate to 5ml, add 25ml of n-hexane, freeze at low temperature, precipitate crystals, filter, wash with n-hexane, and dry in vacuum to obtain the corresponding blue-green semi-sandwiched chromocene olefin Polymerization Catalyst 1c. Yield 51%.

[0026] Elemental Analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com