Continuous vacuum transition chamber with linear vacuum motive seal and X-ray radiation protection function

A protective function and dynamic sealing technology, applied in the field of continuous vacuum transition chamber, can solve the problems of low work efficiency, poor vacuum dynamic sealing effect, difficult X-ray protection, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

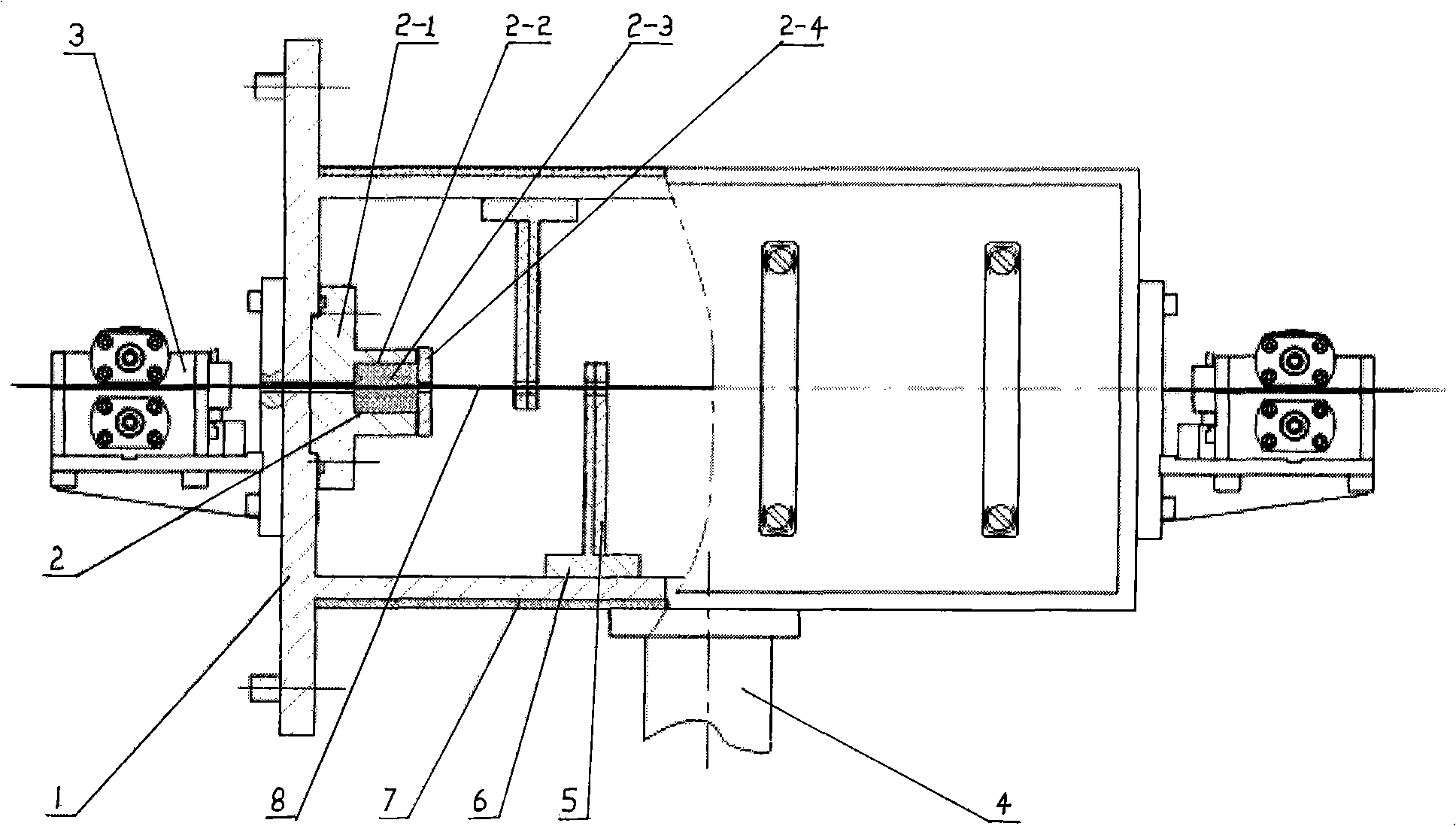

[0012] The continuous vacuum transition chamber of the present invention consists of a transition chamber box body 1, a linear dynamic sealing device 2 in the transition chamber, an adjustable flange sealing frame 2-1, a cover plate 2-2, an upper and lower sealing pressure plate 2-3, and an upper and lower sealing pressure block 2 -4. The guide device at both ends of the box body 3, the vacuum exhaust pipe 4, the lead baffle plate 5, the lead baffle plate bracket 6, and the protective lead 7 outside the transition box. The upper and lower sealing pressure plates 2-3 are made of materials with a small friction coefficient The inner side of the upper and lower sealing pressure plates 2-3 matches the shape of the strip metal 8, the upper and lower sealing pressure plates 2-3 are upper and lower sealing pressure blocks 2-4 made of elastic materials, and the sealing channel is set at more than 2 levels to form a linear The dynamic sealing device 2, X-ray lead baffles 5 with lead pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com