A type glue and method for mending chromium plate white defect by using the same

A technology for repairing glue and white defects is applied in the field of chrome plate repair glue and the field of using the chrome plate repair glue to repair white defects of chrome plate, which can solve the problem that the metal repair solution is not resistant to cleaning by weak alkaline cleaning solution, and the white defect of glass substrate cannot be repaired. The ink cannot repair the problems such as dents and broken lines, so as to reduce the difficulty of repairing, reduce the cost and ensure the adhesion.

Active Publication Date: 2011-10-05

深圳清溢光电股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a chrome plate repair glue. The technical problems to be solved are: the ink cannot repair the depression and disconnection, the metal repair liquid is not resistant to weak alkali cleaning liquid after repair, and the glass substrate cannot be repaired by CVD repair. The problem caused by white defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0024]

[0025]

Embodiment 2

[0027]

Embodiment 3

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

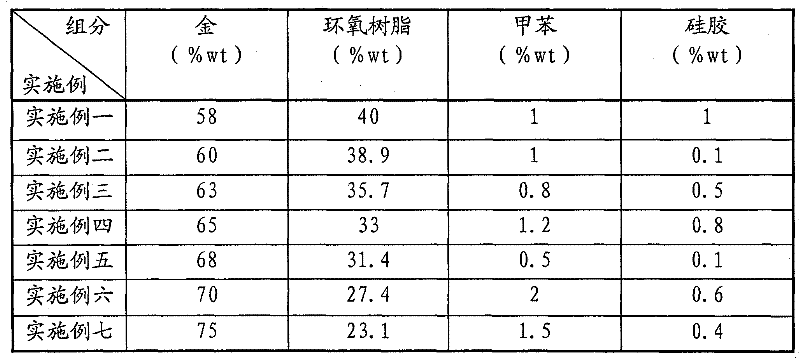

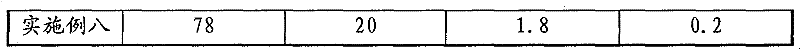

The present invention relates to chromium plate repair sheets which comprises the following raw materials according to the parts by weight: 58-78wt% of a metal nano photoresistive material, 20-40wt% of a curing agent, 0.5%-2wt% of a diluent, and 0.1%-1wt% of a silica gel, the metal nano photoresistive material is any one of powdered gold, silver, nickel, tin or aluminum oxide, the curing agent is epoxy resin or phenolic resin, the diluent is any one of toluene, xylene, trimethylbenzene, turpentine or camphorated oil, and the glass promoter is silica gel. The invention further provides a method for repairing chromium plate white defects by the Chromium plate repair sheets. The provided Chromium plate repair sheets and the method for repairing the chromium plate white defects by the Chromium plate repair sheets solve the problems that printing ink can not repair dent and disconnection, and the chromium plate does not withstand cleaning by weakly alkaline cleaning liquids after being repaired by metal repair solutions, and the white defects caused by a glass substrate can not be repaired by CVD repair; and the glue guarantees the adhesive force of the repaired chromium plate.

Description

technical field [0001] The invention belongs to the technical field of chrome plate defect repairing, and in particular relates to a chrome plate repair adhesive and a method for repairing chrome plate white defects by using the chrome plate repair adhesive. Background technique [0002] The chrome plate is a kind of photomask, also known as a photomask, which is a pattern transfer tool used in the microelectronics manufacturing process. It is made of quartz glass or soda, and the pattern designed by the computer is exposed, Developing, etching and other processes are transferred to the light-blocking material on the surface of the chrome plate to form a new pattern, which is then used in the mass-replication production process of electronic parts. At present, white defects often occur in the production process of chrome plates. The white defects are also called pinhole defects in the industry. They refer to the influence of certain factors during the production and use of c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F1/08G03F1/00G03F1/72

Inventor 王金木

Owner 深圳清溢光电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com