Method for production of chlorogenic acid-containing material

A manufacturing method and technology of chlorogenic acid, applied in the preparation of organic compounds, medical preparations containing active ingredients, preparation of carboxylic acid esters, etc., can solve the problems of limited application to various foods and cosmetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-

[0093] Embodiment 1-(1) and (2)

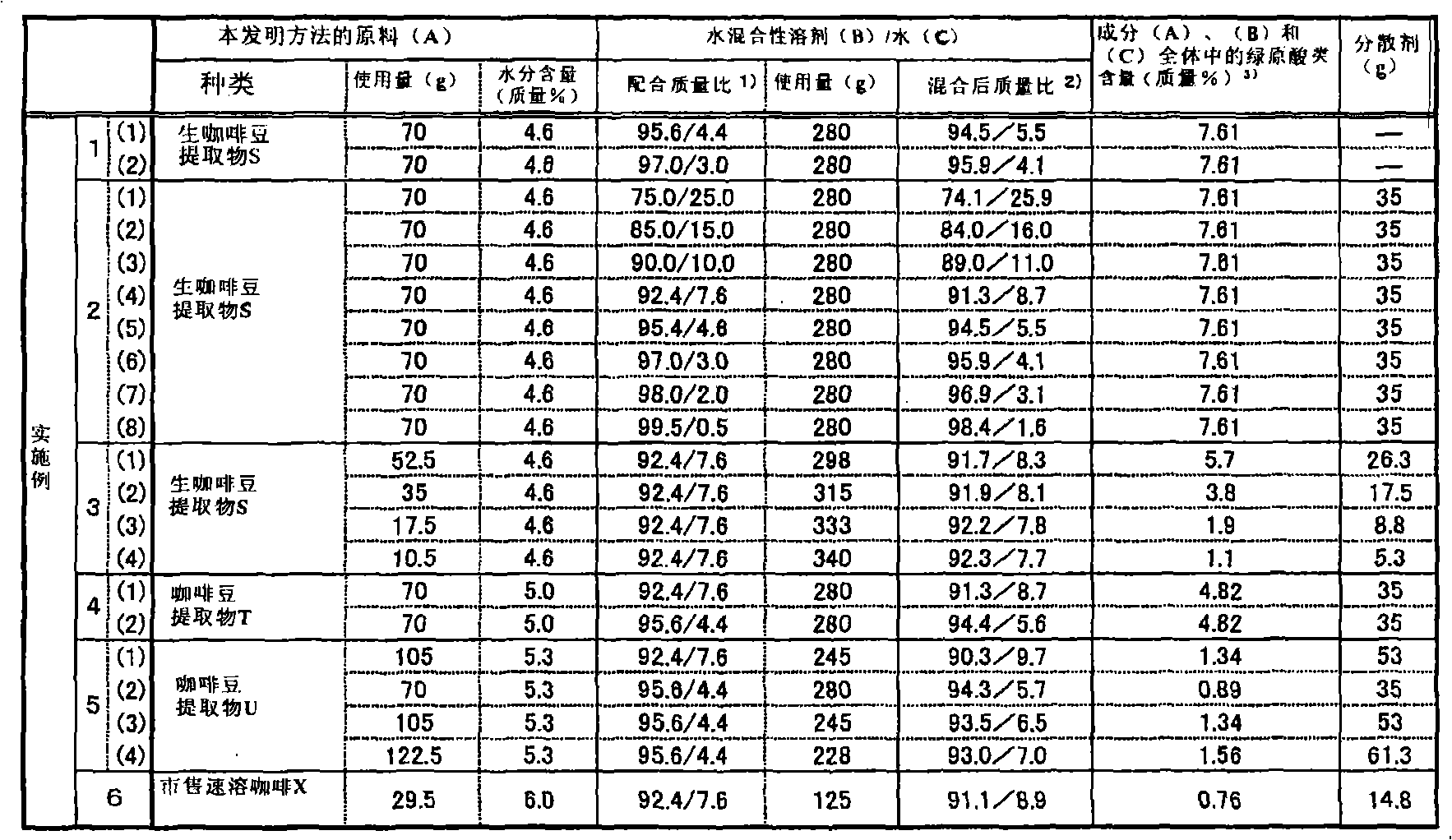

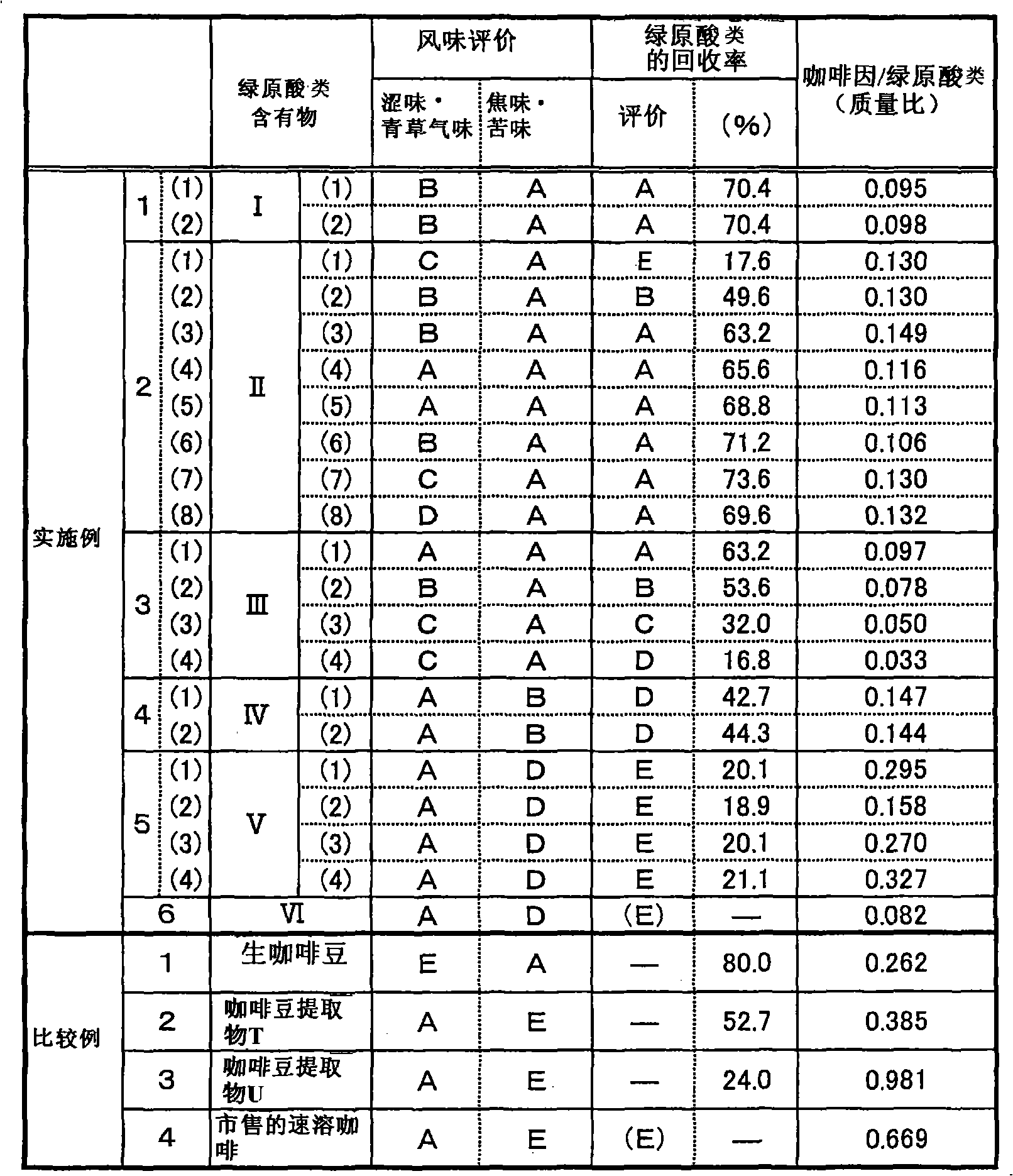

[0094] Mix 70 g of green coffee bean extract S70 g and 280 g of a mixed solvent of ethanol and water (ethanol / water mass ratio shown in Table 1), shake at 60° C. (or 50° C.) for 3 hours to contact, pass through a suction filter (nutsche ) filtration (using No. 2 filter paper) to remove the liquid portion, and the solid portion was washed with 280 g of 99.5% ethanol while directly sucking the filter. This solid part is dissolved in the mixed solvent (ethanol / water mass ratio=30 / 70) 300g of ethanol and water, after carrying out suction filter again (using No. 2 filter paper), wash filter cake with same solvent 300g, thereby recover Soluble components. The recovered fraction was concentrated with an evaporator until the dry solid content was 55% to obtain chlorogenic acid-containing substances I-(1) and (2) obtained by the method of the present invention.

Embodiment 2-

[0095] Embodiment 2-(1)~(8)

[0096] Mix 70 g of green coffee bean extract S, 280 g of a mixed solvent of ethanol and water (mass ratio of ethanol / water shown in Table 1), and 35 g of a dispersant (Silika 100F-A), and shake at 60° C. for 3 hours to make it After contacting, the liquid part was removed by suction filter filtration (using No. 2 filter paper), and the solid part was washed with 280 g of 99.5% ethanol while directly sucking the suction filter. This solid part is dissolved in the mixed solvent (the mass ratio of ethanol / water=30 / 70) 300g of ethanol and water, after filtering with suction filter again (using No. 2 filter paper), wash filter cake with same solvent 300g, thereby Recover the soluble components. The recovered fraction was concentrated with an evaporator to a dry solid content of 55% to obtain chlorogenic acid-containing substances II-(1) to (8) produced by the method of the present invention.

Embodiment 3-

[0097] Embodiment 3-(1)~(4)

[0098] The mixed solvent (mass ratio of ethanol / water shown in Table 1) of the green coffee bean extract S of the amount shown in Table 1, the ethanol of the amount shown in Table 1 and water, and the dispersant of the amount shown in Table 1 ( Silika100F-A) were mixed, shaken at 60°C for 3 hours to bring them into contact, filtered through a suction filter (using No. 99.5% ethanol was used to wash the solid portion of the filter cake. This solid part is dissolved in the mixed solvent (the mass ratio of ethanol / water=30 / 70) 300g of ethanol and water, after filtering with suction filter again (using No. 2 filter paper), wash filter cake with same solvent 300g, thereby Recover the soluble components. The recovered fraction was concentrated with an evaporator to a dry solid content of 55% to obtain chlorogenic acid-containing substances III-(1) to (4) by the method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com