Large-sized flange molding equipment and molding technique

A large-scale flange and forming equipment technology, applied in the direction of metal processing equipment, etc., can solve the problems of long processing time, difficult operation of equipment, poor quality of finished products, etc., and achieve the effect of high processing efficiency, easy maintenance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Now in conjunction with accompanying drawing, the present invention is described in further detail:

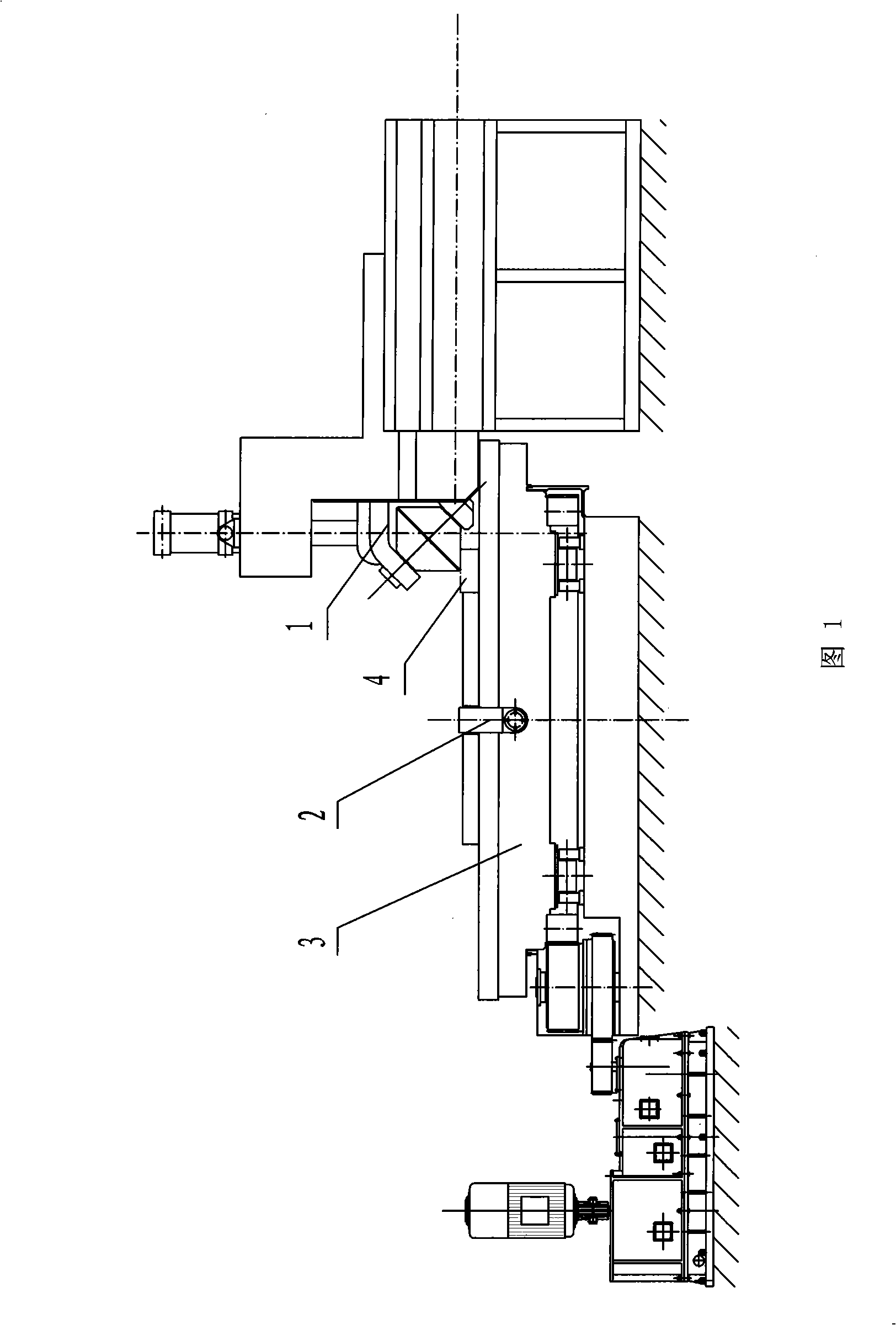

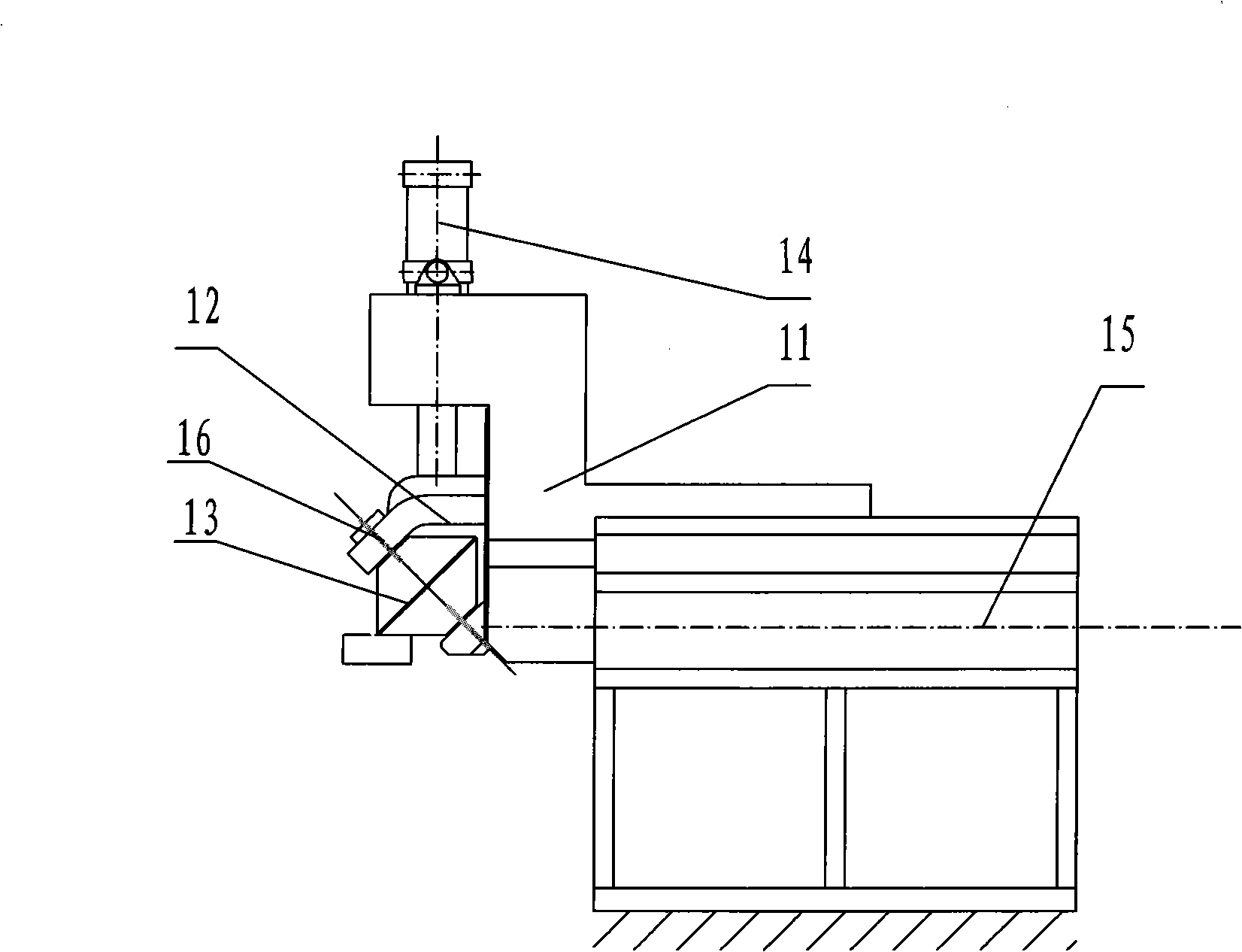

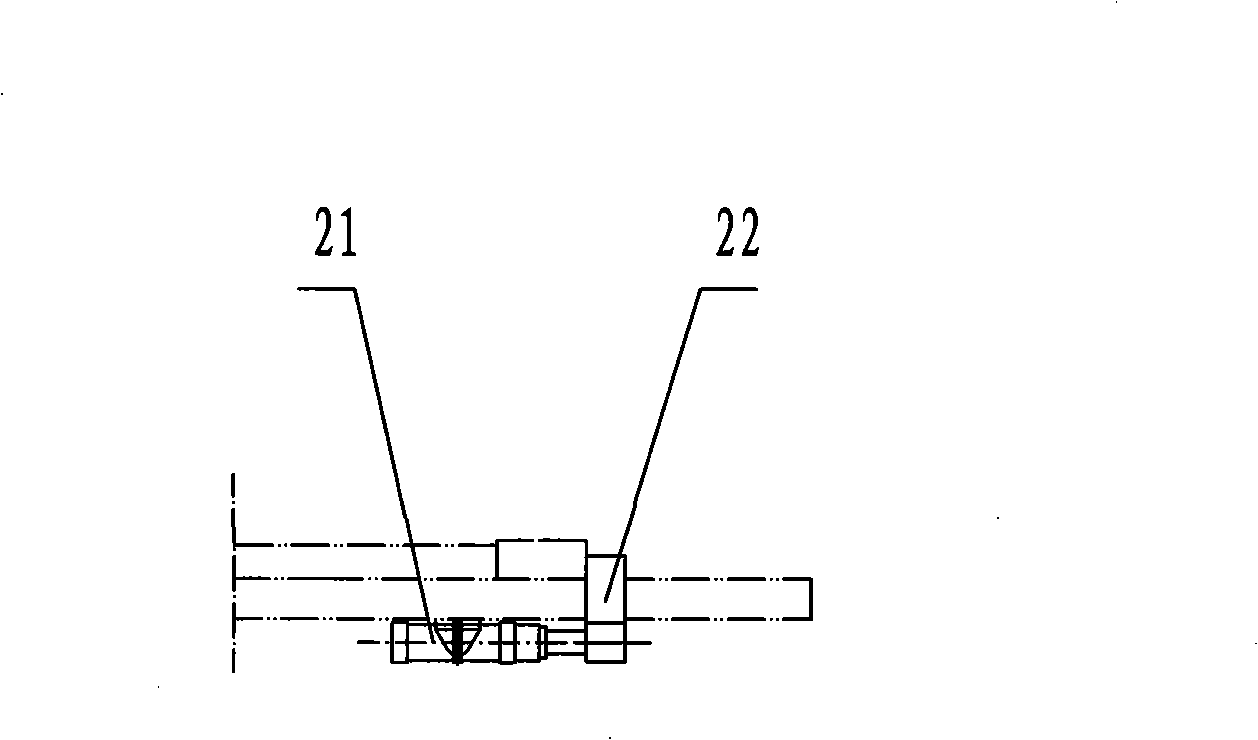

[0050] Described large-scale flange forming equipment, as shown in Figure 1, comprises material-pressing device 1, clamping device 2 and rotary device 3, and described material-pressing device 1 comprises mobile frame 11, slide block 12, pressure roller 13 and Lifting hydraulic cylinder 14, the clamping device 2 includes a clamping hydraulic cylinder 21 and a clamping block 22, and the turning device 3 includes a motor 31, a reducer 32, a turning platform 34 and idlers 33;

[0051] The pressing device 1, such as figure 2 As shown, the mobile frame 11 includes a guide rail 15, and the mobile frame 11 moves laterally along the guide rail 15 to the side of the rotary platform 34 under the action of the hydraulic cylinder; the lifting hydraulic cylinder 14 is fixedly installed on the mobile frame 11, The slide block 12 is fixedly coupled with the piston rod of the lifting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap