Nailing gun

A nailing gun and nailing technology, which is applied in the field of nailing guns, can solve the problems of inability to hit continuously, the structure is not compact, and the efficiency of pushing nails is low, and achieves the effect of outstanding substantive characteristics, compact structure, and continuous and efficient hitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

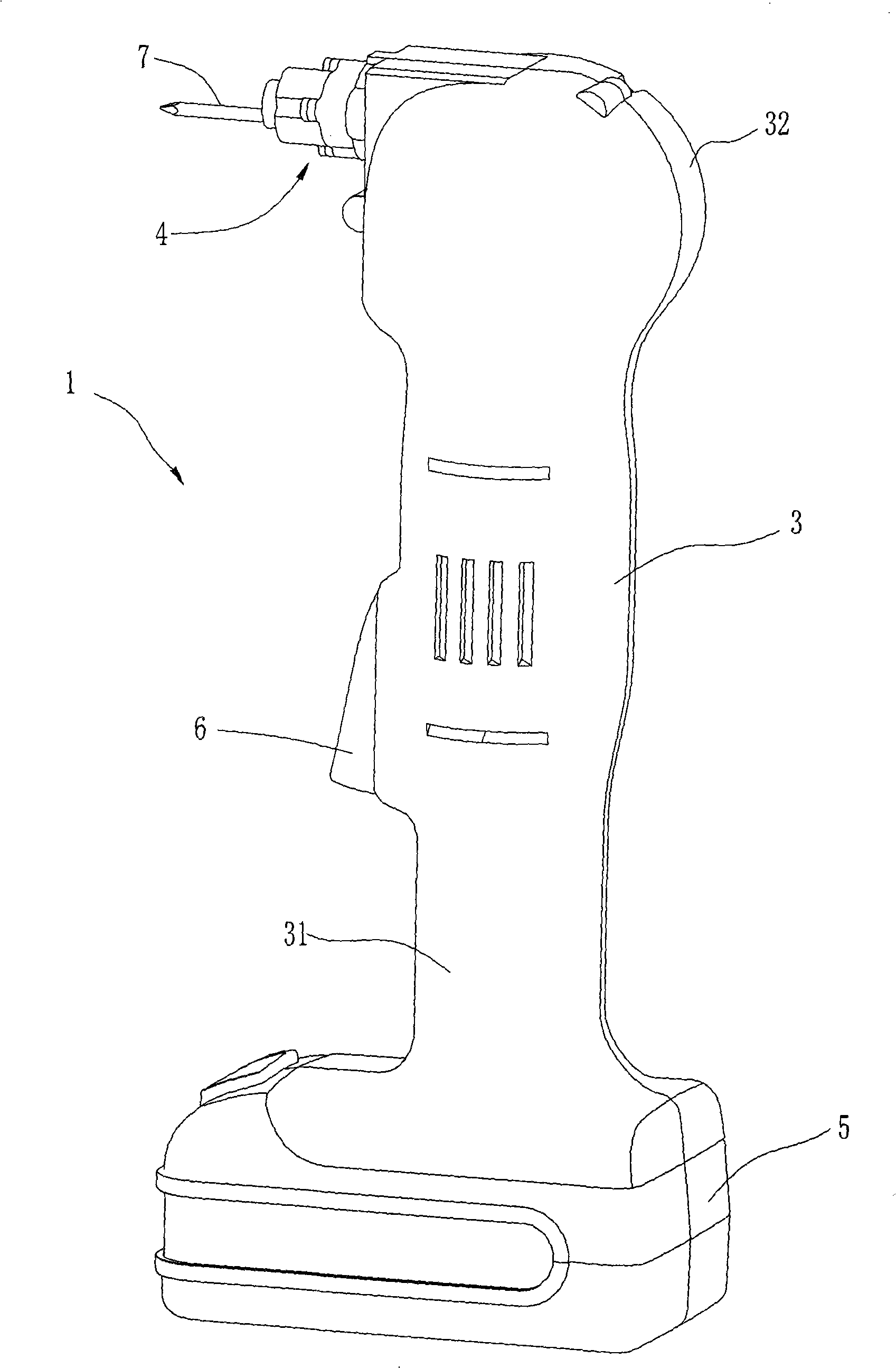

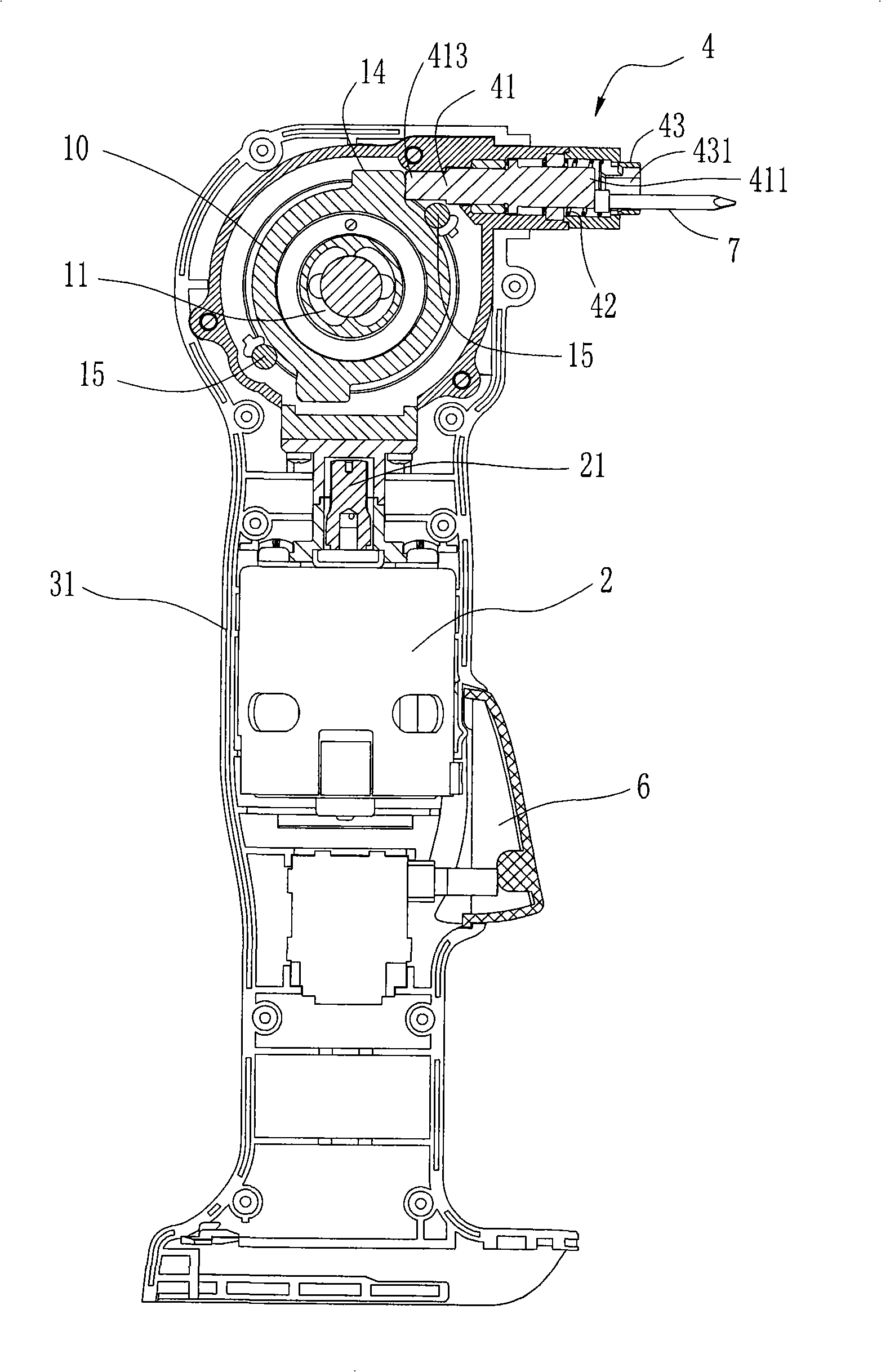

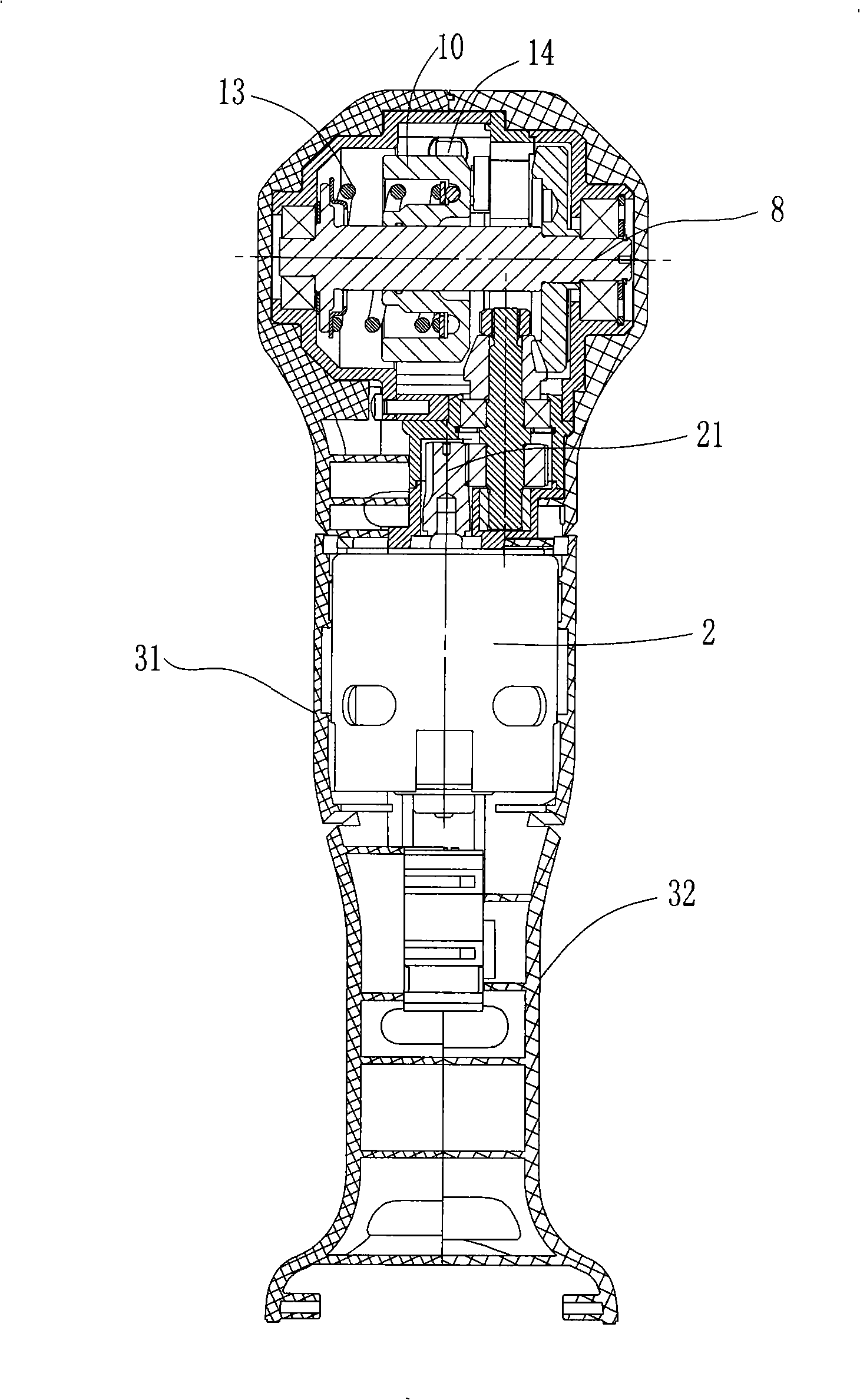

[0025] Such as figure 1 with figure 2 As shown, the nailing gun 1 of this embodiment includes a casing 3 containing the motor 2 and a gun nozzle part 4. The casing 3 is formed by combining two halves of the casing 31, 32 to form an accommodating space. The main part of the casing 3 forms an elongated handle, the upper part of the main part has a hole, and at least a part of the muzzle part 4 protrudes from the hole.

[0026] In this embodiment, the nailer 1 includes a battery pack 5 for powering the motor 2 . However, the power supply mode of the nailing gun disclosed in the present invention is not limited thereto, and AC power can also be used for power supply. The switch 6 is installed on the casing 3 and is connected with the motor control circuit for controlling the start and stop of the motor 2 . The gun nozzle part 4 comprises a nailing rod 41 that can push away the nail 7, and the nail driving rod 41 is substantially perpendicular to the longitudinal direction of t...

Embodiment approach 2

[0036] The nailing gun of present embodiment two is as Figure 8 , Figure 9 with Figure 10 As shown, although the appearance is obviously different from that of Embodiment 1, the casing 30 after removing the battery pack is T-shaped, and the motor 20 is not vertically placed on the handle, but horizontally placed on the gun mouth portion at the front end of the casing 30 40, but its internal transmission mechanism and striking working principle are basically the same, so I won’t repeat them here.

[0037] Except that there are differences in the shapes of individual parts, the significant difference between the second embodiment and the first embodiment in the transmission mechanism and striking principle is that there is no stop pin in the nailing gun of the present embodiment. In actual operation, during the process of driving the nail into a relatively hard object, or the nail has been completely driven into the object, the driving rod may be subjected to a large impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com