Bamboo wood beating and fiber opening machine

A fiber machine and bamboo technology, used in wood processing, mechanical equipment, sugarcane machining, etc., can solve the problems of fiber breakage and unsatisfactory effect, and achieve the effect of reducing damage, facilitating subsequent finishing, and reducing fiber cleaning equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

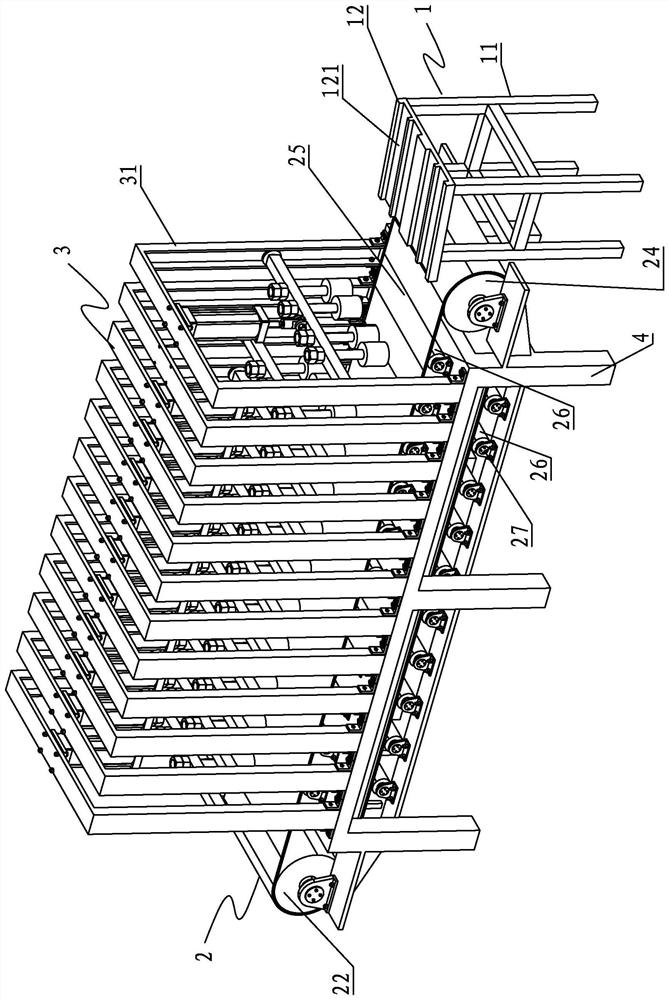

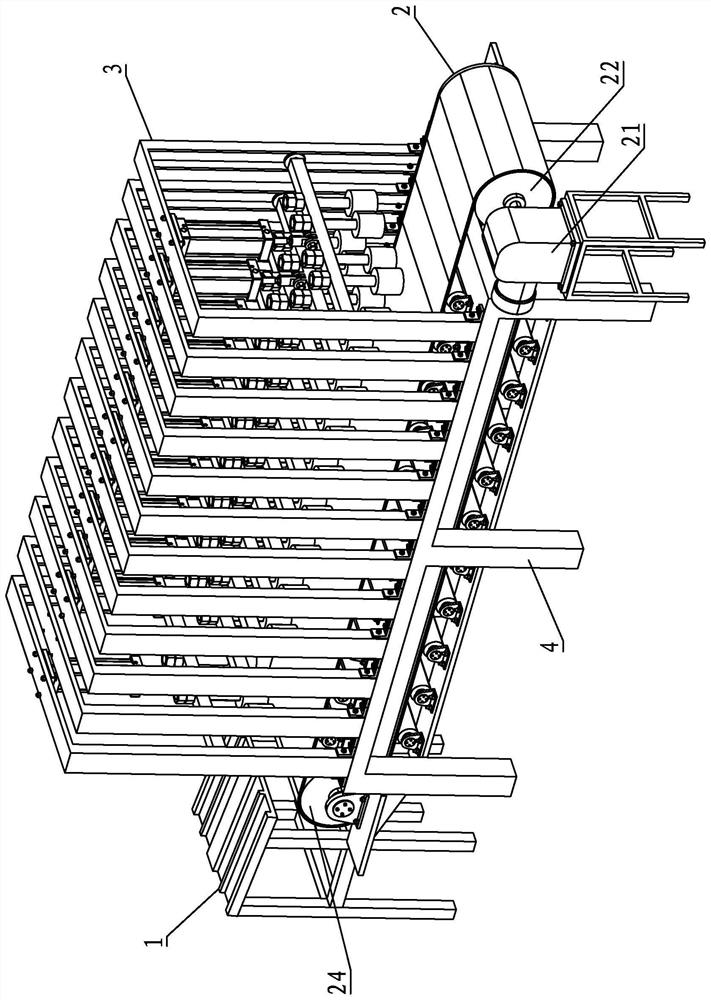

[0038] A bamboo splitting machine is composed of a feeding part 1, a transmission device 2, a beating device 3, and a frame 4, such as figure 1 , figure 2 shown. The feeding part 1 is composed of a feeding frame 11 and a feeding guide plate 12 , and a plurality of parallel guiding grooves 121 are opened on the feeding guide plate 12 . The height of the feeding rack 11 is adapted to the conveyor belt, the number of the guide grooves 121 is even, the position corresponds to the hammer 36 described below, and the width is smaller than the diameter of the hammer.

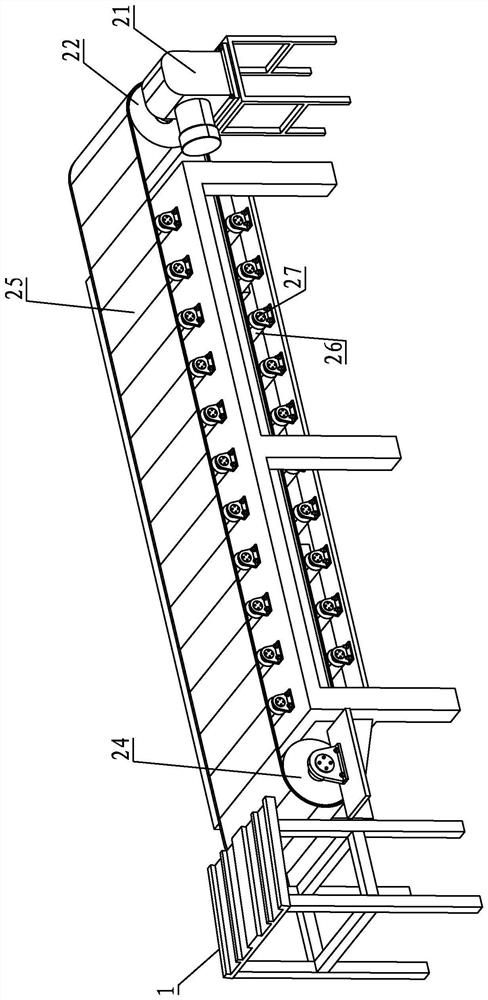

[0039] Bamboo chip transfer device 2 such as image 3 , Figure 4 As shown, the chain plate conveyor belt is driven by the motor through the chain drive, so that the bamboo pieces move continuously. The deceleration motor 21 drives the driving sprockets 22 on both sides of the chain plate 25 to rotate through the coupling, and the driving chain wheel 22 drives the driven chain wheel 24 to move through the chain 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com