Upright post type LED heat radiator

A LED heat sink and column technology, which is applied in the direction of electric solid-state devices, semiconductor devices, lighting and heating equipment, etc., can solve the problems of poor matching of LED heat dissipation structure, high cost of heat pipe technology, and easy dust accumulation on heat sink, so as to reduce the temperature , compact structure, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

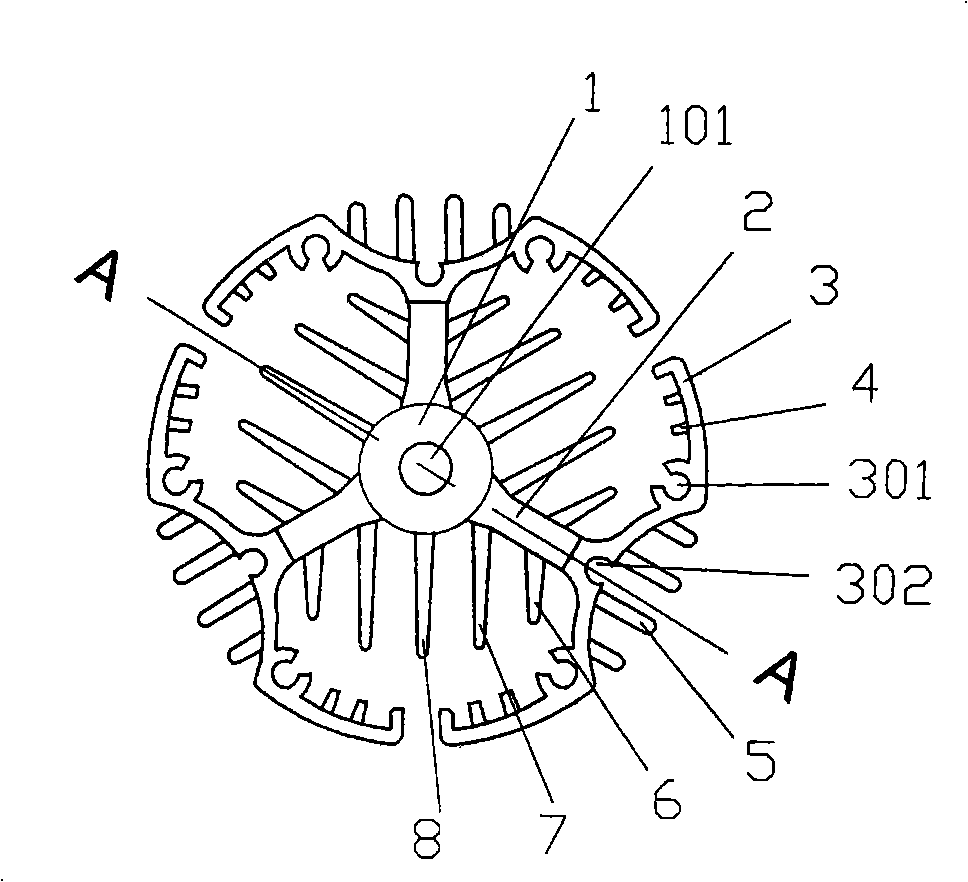

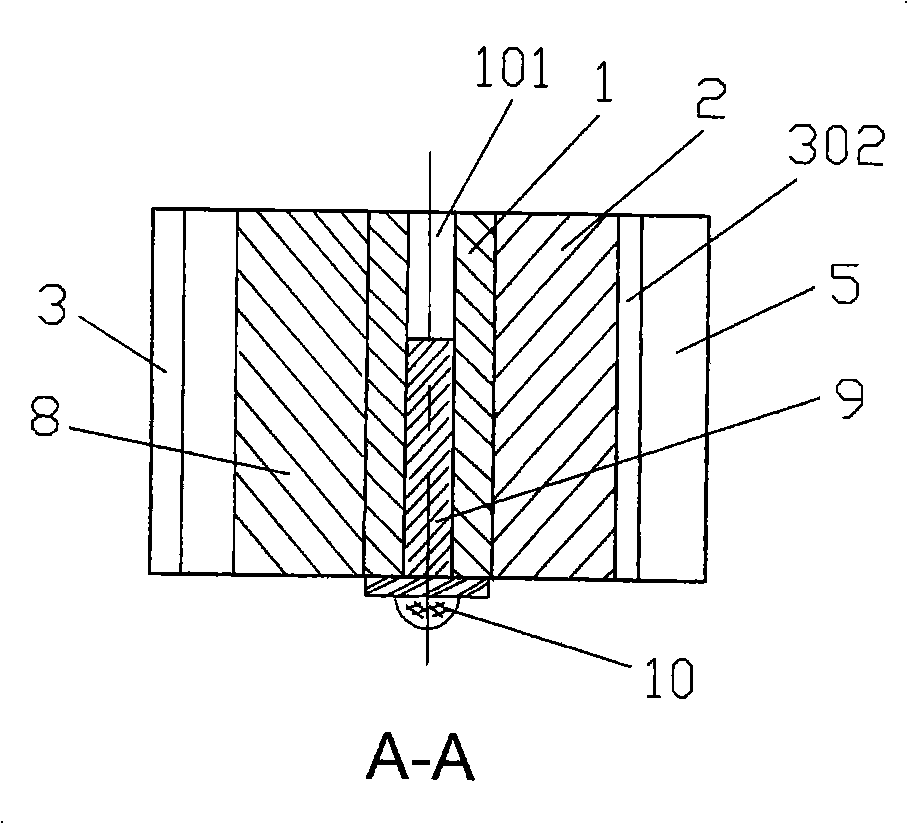

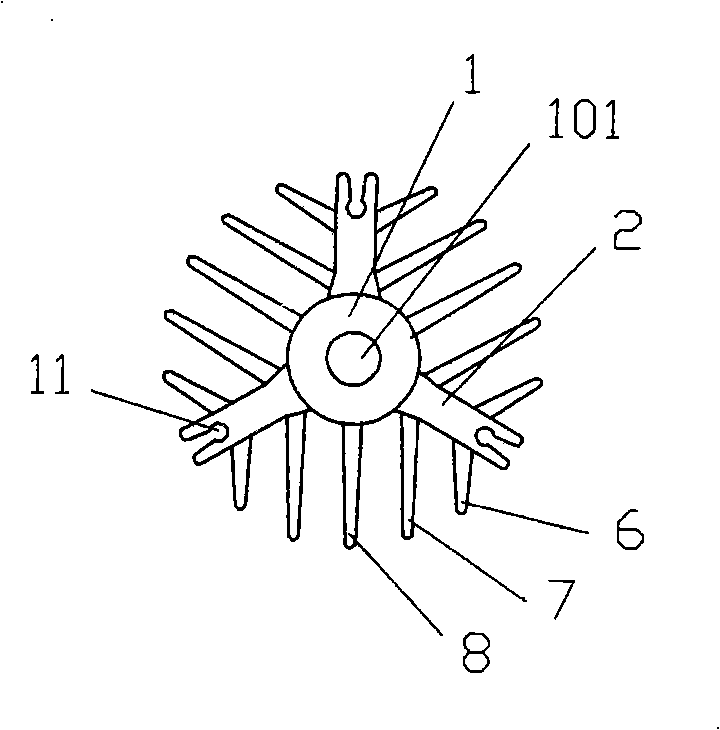

[0015] Depend on Figure 1 ~ Figure 3 As shown, the present invention includes a column-type heat conductor 1, a heat transfer sheet 2, a heat dissipation housing 3 and a high-power LED10, and a column-shaped hole 101 is opened in the column-type heat conductor 1. In order to quickly reduce the temperature of the high-power LED10, the A thermal conductor 9 is inserted into one side of the column-shaped hole 101 , and a high-power LED 10 is fixed on the end faces of the column-shaped thermal conductor 1 and the thermal conductor 9 .

[0016] The shape of the so-called heat conductor 9 is an aluminum sheet, an aluminum rod, a copper sheet, a copper rod, a copper tube with one side closed, and a heat pipe. Because of the power of the high-power LED 10, its calorific value is different, so one of the above forms can be selected according to the structure of the lamp and the power of the LED used. Generally, when the power of the LED lamp is relatively high, the copper material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com