Method for preserving carotenoid in garden stuff juice using superhigh pressure technology

An ultra-high pressure technology and carotene technology are applied in the processing field of ultra-high pressure preservation of functional components in fruit and vegetable juices, and can solve the problems of improper processing methods, low carotenoid content, and reduced biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

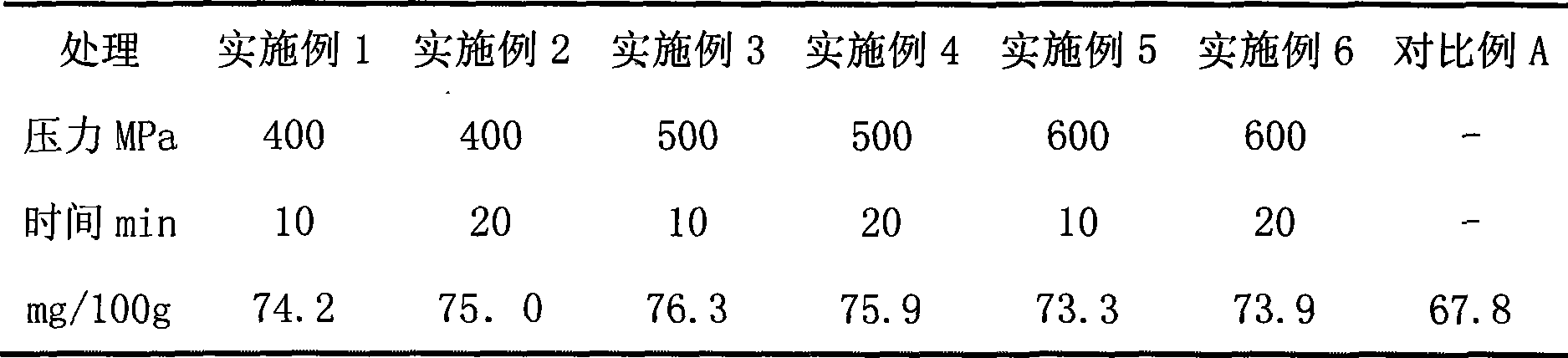

[0016] The raw materials for preparing carrot juice include: carrots, citric acid, Vc, honey, syrup, deionized water, etc. The process method is as follows: select fresh orange-red carrots with darker color, wash and peel, slice (3-5mm), and then pre-preserve the carrot slices in 0.5% citric acid and 0.5% Vc compound blanching liquid at about 95°C. Boil for 1 min, and cool quickly with cold water, then add deionized water to make a slurry with a material-to-liquid ratio of 1:1, grind the colloid to a fine, slag-free and particle-free homogenate of about 200 mesh, and then adjust the obtained carrot juice to pH4 .0, add syrup or honey to adjust the soluble solids content to 10%, homogenize at 35MPa pressure, and then vacuum degas at 40°C and 450mmHg for 1min. Keep it under 400MPa ultra-high pressure and normal temperature for 10 minutes, and carry out aseptic filling. Then, the carotenoid content in carrots was measured, and the measurement results are listed in Table 1.

Embodiment 2

[0018] The ultra-high pressure carrot juice process is the same as in Example 1. Ultra-high pressure treatment: keep the pressure at 400MPa for 20 minutes at room temperature, and carry out aseptic filling. Then, the carotenoid content in carrots was measured, and the measurement results are listed in Table 1.

Embodiment 3

[0020] The ultra-high pressure carrot juice process is the same as in Example 1. Ultra-high pressure treatment: keep the pressure at 500MPa for 10 minutes at room temperature, and carry out aseptic filling. Then, the carotenoid content in carrots was measured, and the measurement results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com