Improved powdered coke scraper conveyor

A technology of scraper machine and powder coke, which is applied in the direction of clockwork mechanism, coking oven, hoisting device, etc., can solve the problems of low efficiency, environmental pollution, easy blockage of the coke discharge channel of the coke washing tank, etc., and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

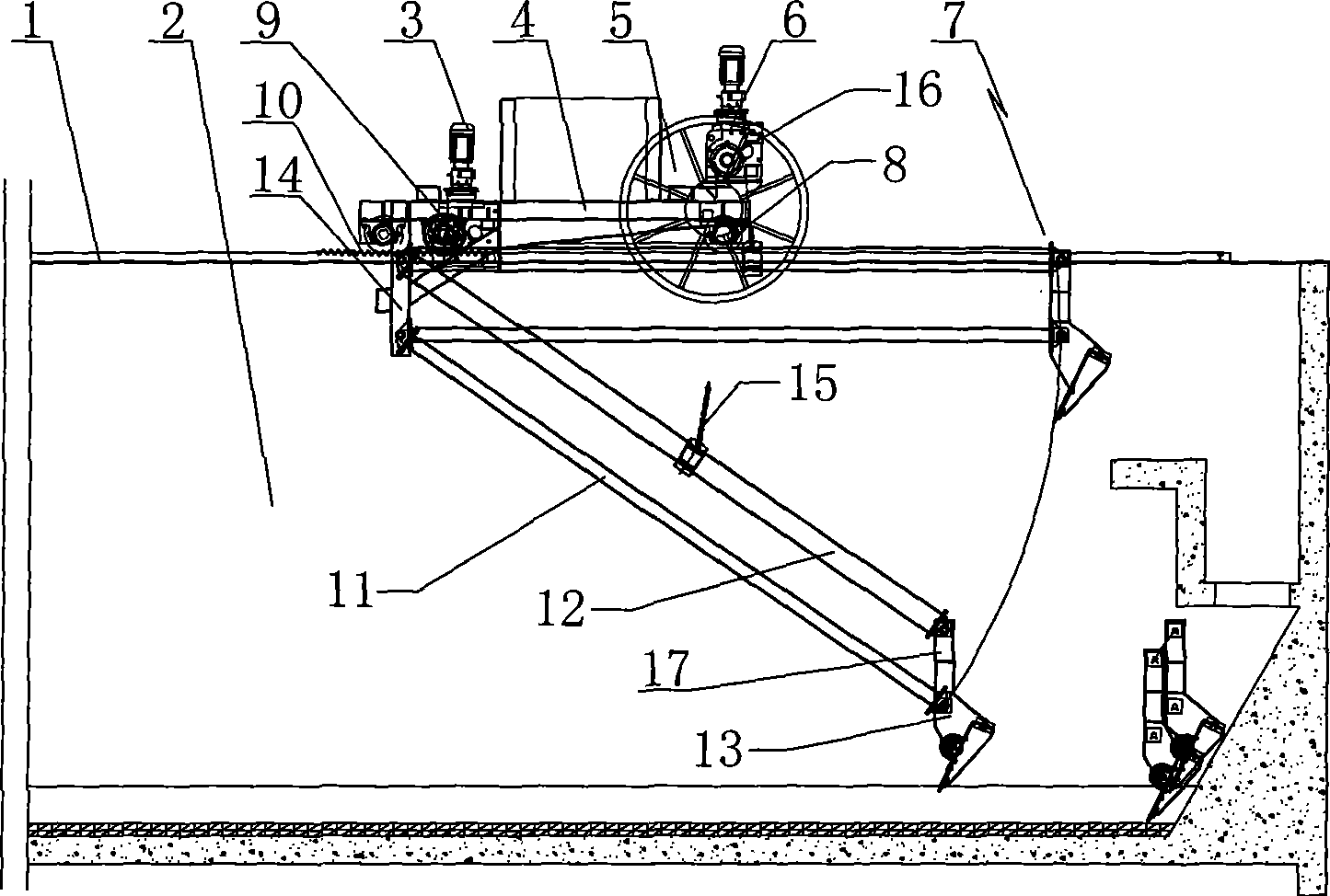

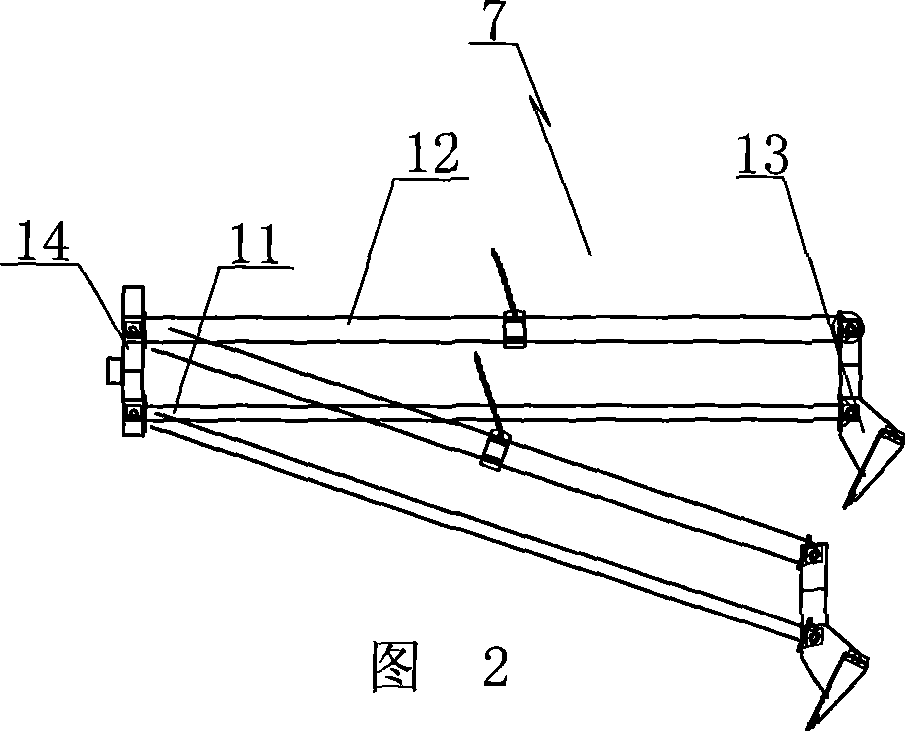

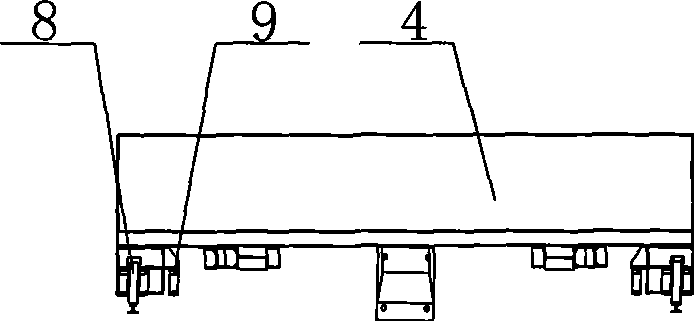

[0012] See figure 1 , the present invention includes a mechanical part and an automatic control system. The mechanical part includes a transmission device, a travel transmission mechanism, a hoisting mechanism 7, and a running track 1. The automatic control system and the mechanical part are connected by PLC electric control. The running track 1 is installed above the powder coke pool 2; see image 3 , Figure 4 , the transmission device includes a gear 9 and a rack 10, the gear 9 is installed on the bottom of both ends of the traveling cart 4, the rack 10 is installed on the running track 1, the gear 9 is meshed with the rack 10, and the gear 9 is connected to the shaft of the traveling transmission mechanism , the bottom of the two ends of the walking cart 4 is equipped with a bearing mechanism; the bearing mechanism includes four bearing rollers 8, the bearing rollers 8 are installed on the bottoms of both sides of the walking cart 4 two ends, and the bearing rollers 8 rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com