Magnesium metal reduction apparatus

A metal magnesium and magnesium reduction tank technology, applied in the field of thermal magnesium reduction devices, can solve the problems of difficulty in pollutant discharge, short service life of magnesium reduction tanks, insufficient material reduction, etc., so as to save daily maintenance work and maintenance. People and costs, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

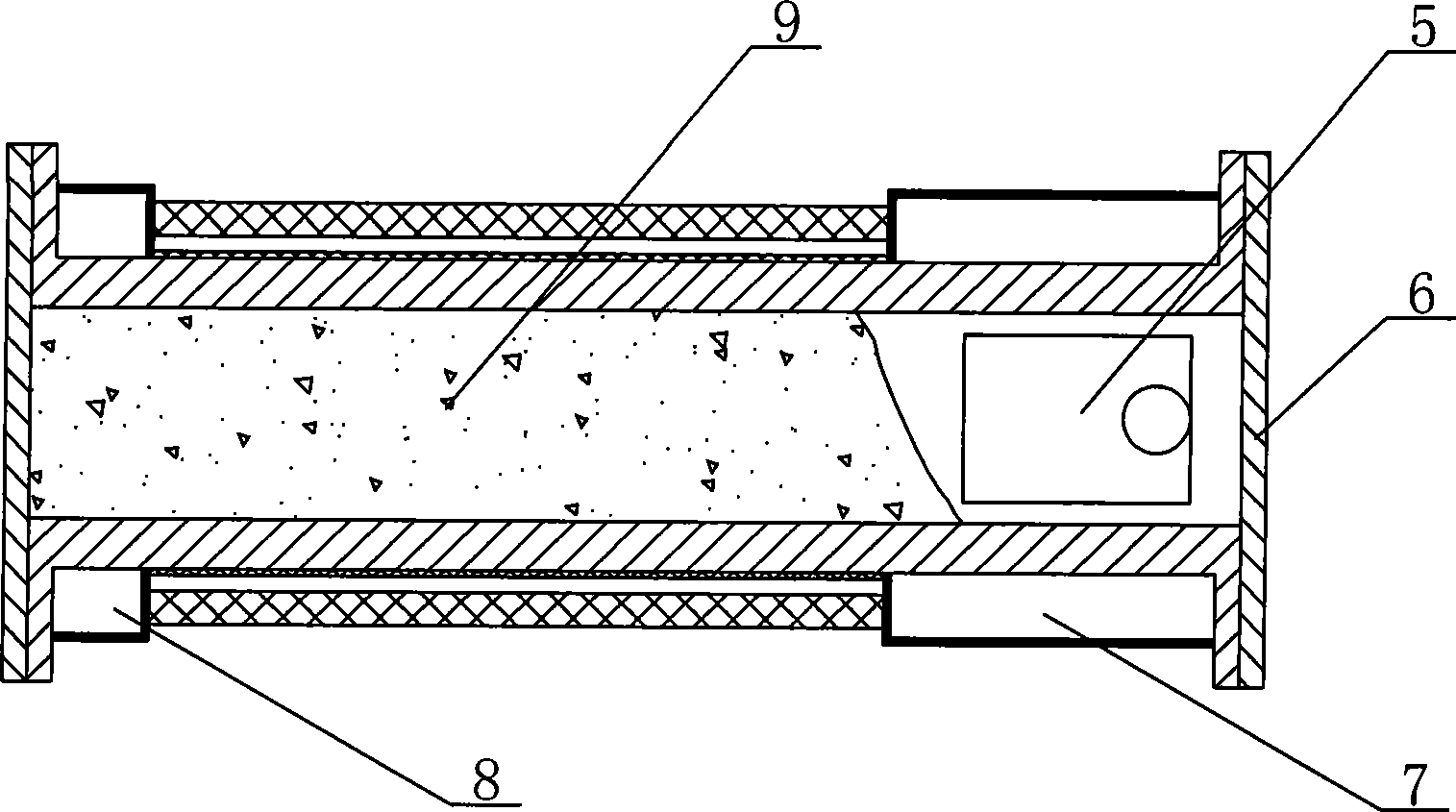

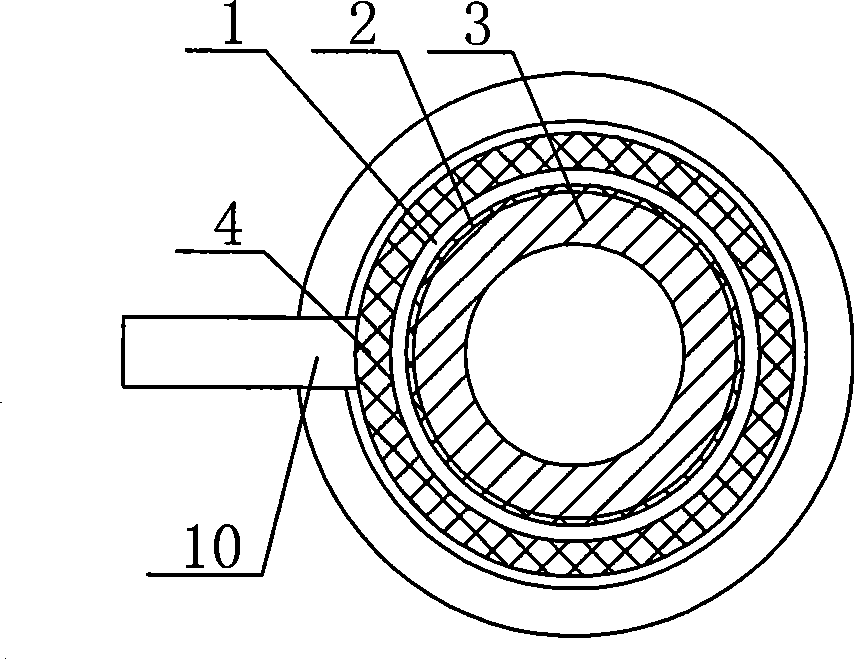

[0032] Such as figure 1 , figure 2 As shown, a metal magnesium reduction device of the present invention is implemented in the following way: on the outer surface of the tank body 3 of the magnesium reduction tank, an insulating protective layer 2 with high temperature resistance and good thermal conductivity is laid, and the outer peripheral surface of the insulating protective layer 2 is installed Magnesium reduction electric heater 1 is arranged to supply the heat required for metal magnesium reduction in the tank. The magnesium reduction electric heater 1 is provided with a rigid composite shell 4 outside, and its function is to insulate, keep warm and protect the magnesium reduction electric heater from being damaged by external force. The steam-like magnesium metal after reduction is condensed and crystallized on the crystallizer 5 to form a primary product of magnesium metal. The canning of the reduced material 9 and the slag discharge operation are carried out after...

Embodiment 2

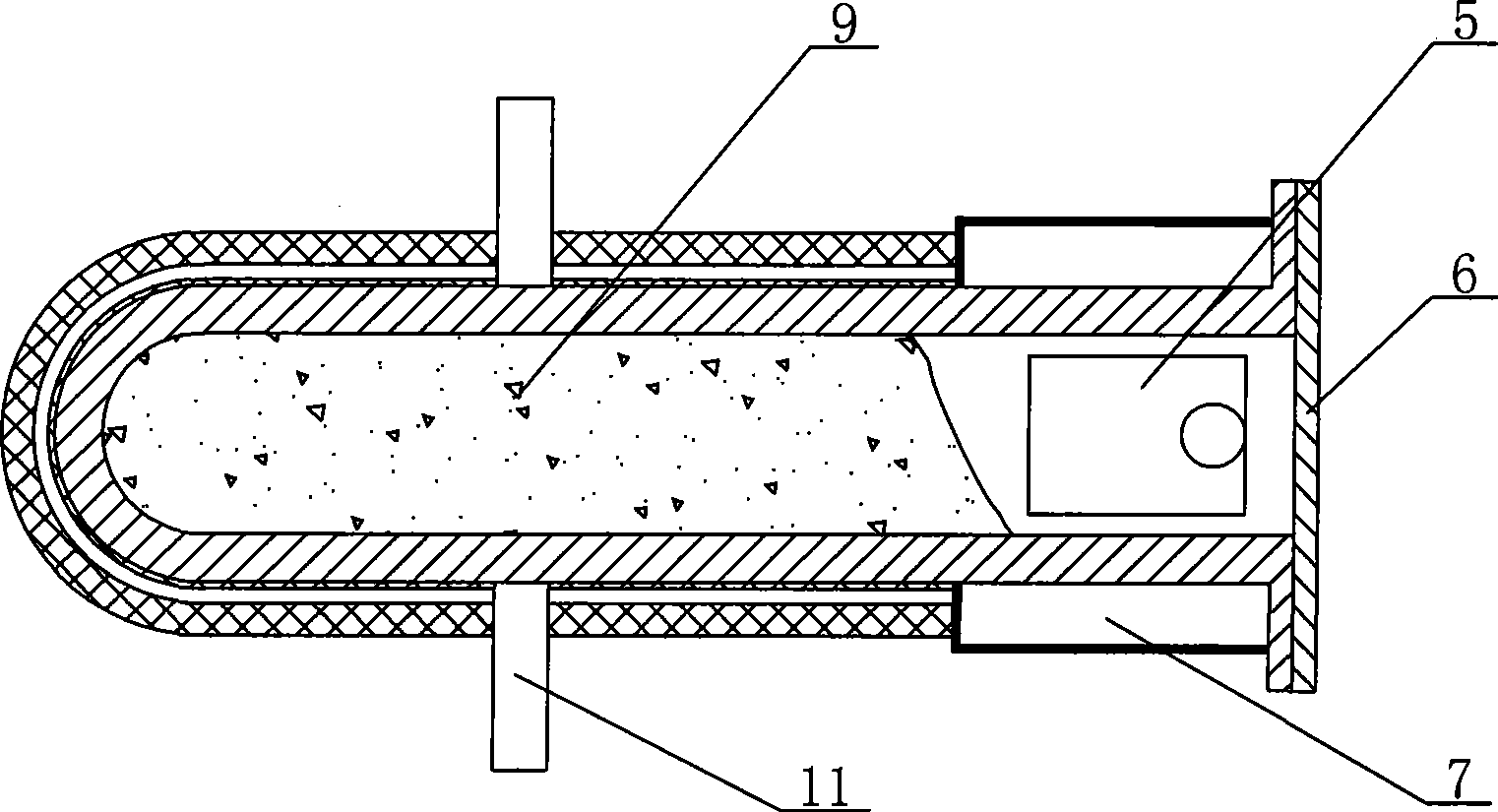

[0034] Such as image 3 with Figure 4 As shown, the charging port and the slag outlet are opened on the same side of the tank body 3 of the magnesium reduction tank. The rear part of the tank body 3 of the magnesium reduction tank is a "U"-shaped structure. Connected, the overturning shaft 11 is connected with the overturning mechanism that drives it to rotate, and the overturning shaft 11 is driven by the overturning mechanism to rotate the metal magnesium reduction device to a suitable operating angle. Other structures are the same as in Embodiment 1.

[0035] The present invention is an independent single metal magnesium reduction device that can be moved in multiple ways, and one or more single metal magnesium reduction devices can be combined in various ways according to the process requirements of the vacuum unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com