Supercharging mode-variable turbocharging system with turbo in the middle part

A turbocharging system and turbine technology, applied in gas turbine devices, engine components, machines/engines, etc., can solve the problems of low turbine efficiency, failure to form, and large exhaust interference, etc., to achieve excellent performance, reasonable design, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

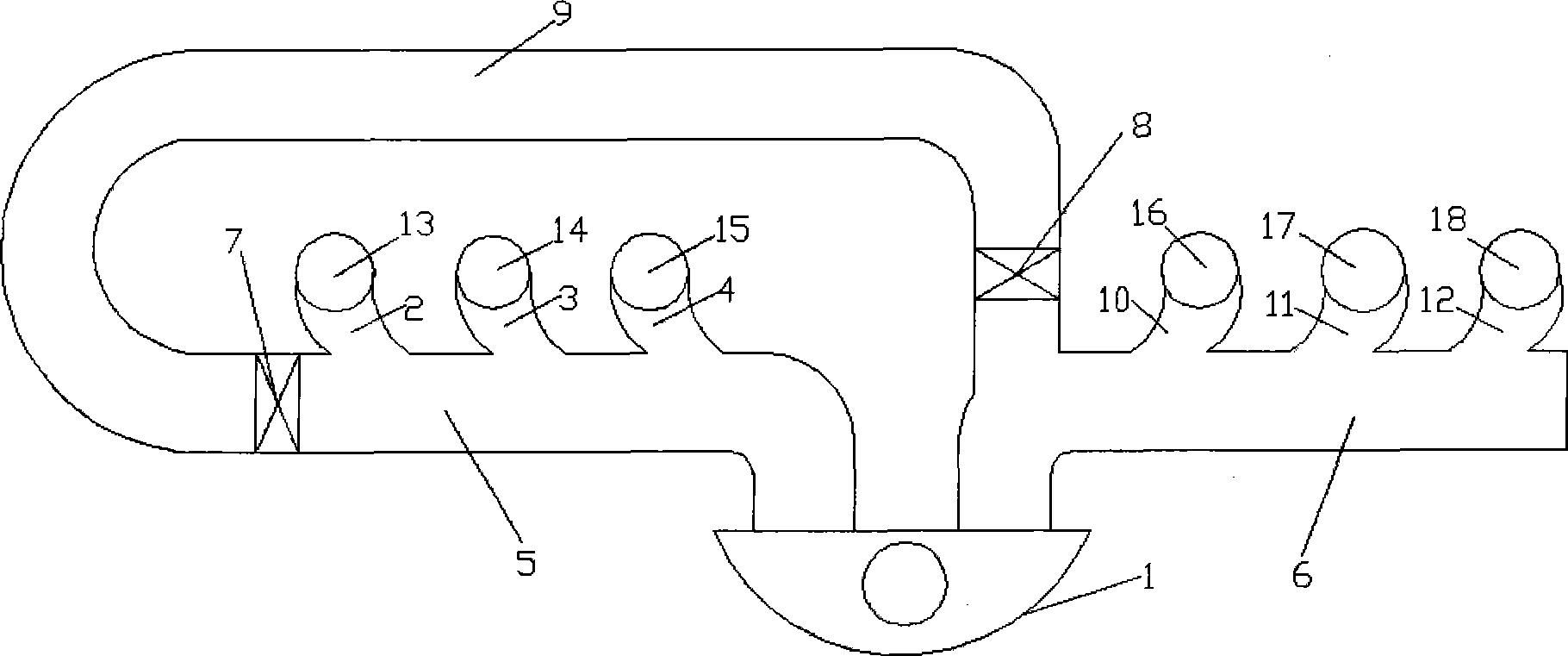

[0009] Such as figure 1 As shown, the present invention comprises a first cylinder 13, a second cylinder 14, a third cylinder 15, a fourth cylinder 16, a fifth cylinder 17, a sixth cylinder 18, a first exhaust branch pipe 2, a second exhaust branch pipe 3, The third exhaust branch pipe 4, the fourth exhaust branch pipe 10, the fifth exhaust branch pipe 11, the sixth exhaust branch pipe 12, the first exhaust pipe 5, the second exhaust pipe 6, the turbine 1, the first valve 7, The second valve 8 and the connecting pipe 9, the first cylinder 13, the second cylinder 14, and the third cylinder 15 respectively pass through the first exhaust branch pipe 2, the second exhaust branch pipe 3, the third exhaust branch pipe 4 and the first exhaust branch pipe. The pipes 5 are connected, and the fourth cylinder 16, the fifth cylinder 17, and the sixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com