Hollow glass micro bead reinforcement rigid polyvinyl chloride material and preparation method thereof

The technology of hard polyvinyl chloride and glass microbeads is applied in the field of hollow glass microbeads reinforced hard polyvinyl chloride material and its preparation, which can solve the problems of complicated preparation process, unfavorable industrial production and the like, and achieves simple process, low production cost, Improve the effect of application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of Hollow Glass Microspheres Reinforced Rigid Polyvinyl Chloride Material

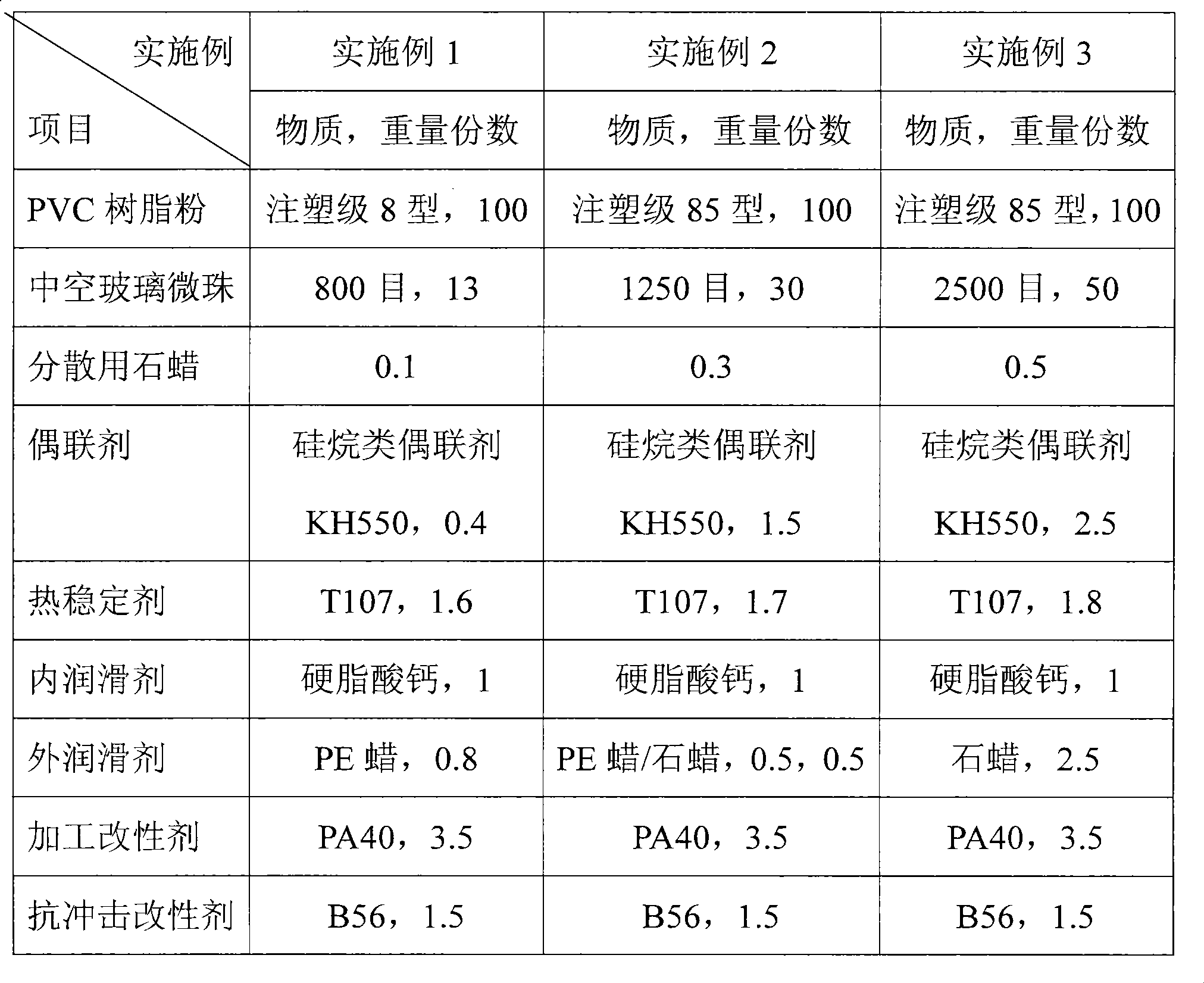

[0034] The hollow glass microsphere reinforced hard polyvinyl chloride material of this example, its components and parts by weight are shown in the part of Example 1 in Table 1.

[0035] The hollow glass microsphere reinforced hard polyvinyl chloride material of the present embodiment, its preparation method comprises the following steps:

[0036] (1) Pre-coupling treatment: first spray the hollow glass microspheres with a coupling agent, and the hollow glass microspheres are 800 mesh;

[0037] (2) Preparation of treatment material: PVC resin powder is added in the hollow glass microspheres after the above-mentioned treatment, and paraffin wax for dispersing is added, and then mixed at a high speed;

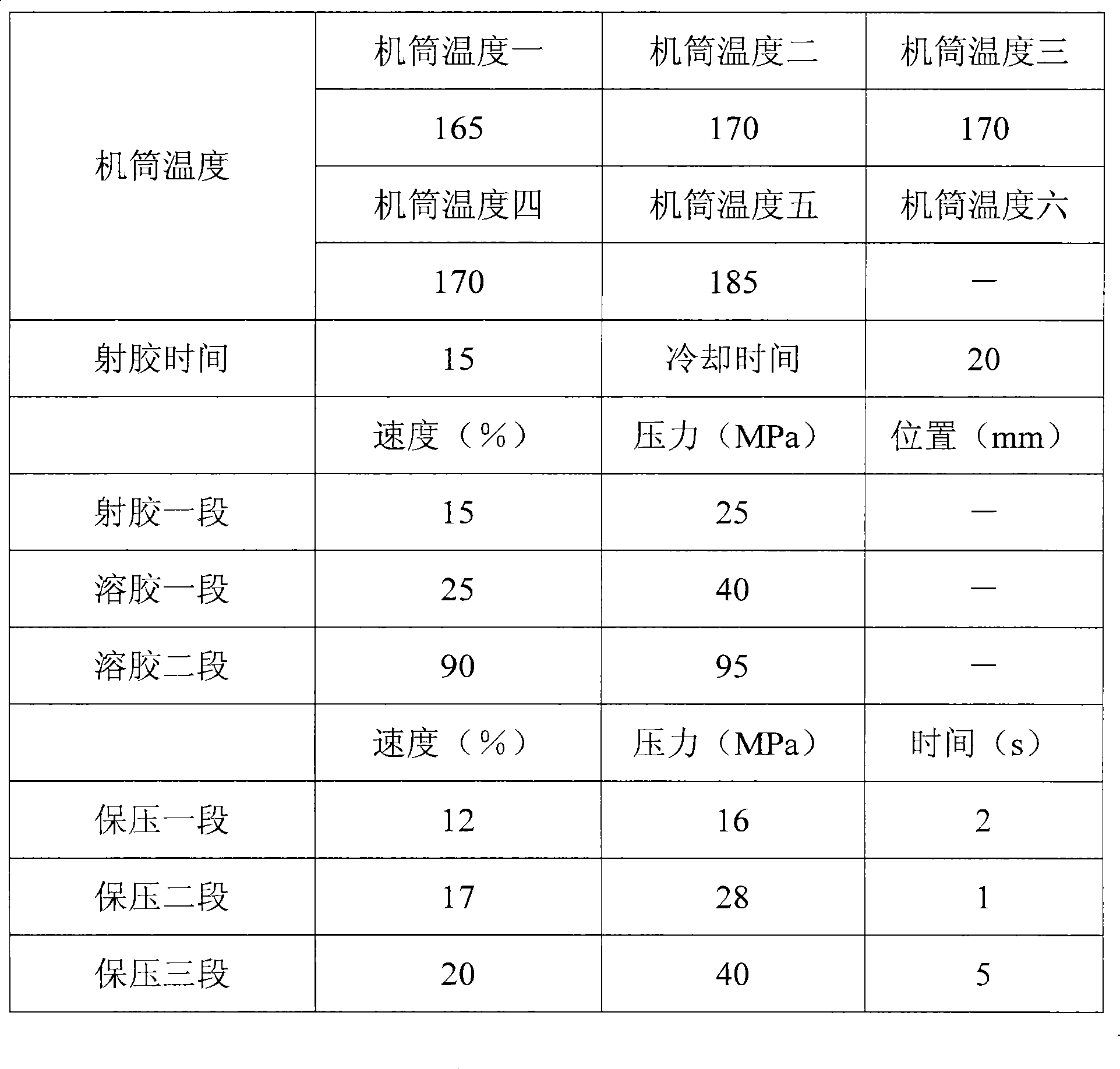

[0038] (3) Prepare mixed ingredients: mix the above-mentioned mixed treatment materials with heat stabilizers, lubricants, processing modifiers, impact modifiers, etc. at hi...

Embodiment 2

[0045] Example 2 Preparation of Hollow Glass Microspheres Reinforced Rigid Polyvinyl Chloride Material

[0046] The hollow glass microsphere reinforced hard polyvinyl chloride material of this embodiment, its components and parts by weight are shown in the part of Example 2 in Table 1.

[0047] The hollow glass microsphere reinforced hard polyvinyl chloride material of the present embodiment, its preparation method comprises the following steps:

[0048] (1) Pre-coupling treatment: first spray the hollow glass microspheres with a coupling agent, and the hollow glass microspheres are 1250 mesh;

[0049] (2) Preparation of treatment material: PVC resin powder is added in the hollow glass microspheres after the above-mentioned treatment, and paraffin wax for dispersing is added, and then mixed at a high speed;

[0050] (3) Prepare mixed ingredients: mix the above-mentioned mixed treatment materials with heat stabilizers, lubricants, processing modifiers, impact modifiers, etc. a...

Embodiment 3

[0055] Example 3 Preparation of Hollow Glass Microspheres Reinforced Rigid Polyvinyl Chloride Material

[0056] The hollow glass microsphere reinforced hard polyvinyl chloride material of this embodiment, its components and parts by weight are shown in the part of Example 3 in Table 1.

[0057] The hollow glass microsphere reinforced hard polyvinyl chloride material of the present embodiment, its preparation method comprises the following steps:

[0058] (1) Pre-coupling treatment: first spray the hollow glass microspheres with a coupling agent, and the hollow glass microspheres are 2500 mesh;

[0059] (2) Preparation of treatment material: PVC resin powder is added in the hollow glass microspheres after the above-mentioned treatment, and paraffin wax for dispersing is added, and then mixed at a high speed;

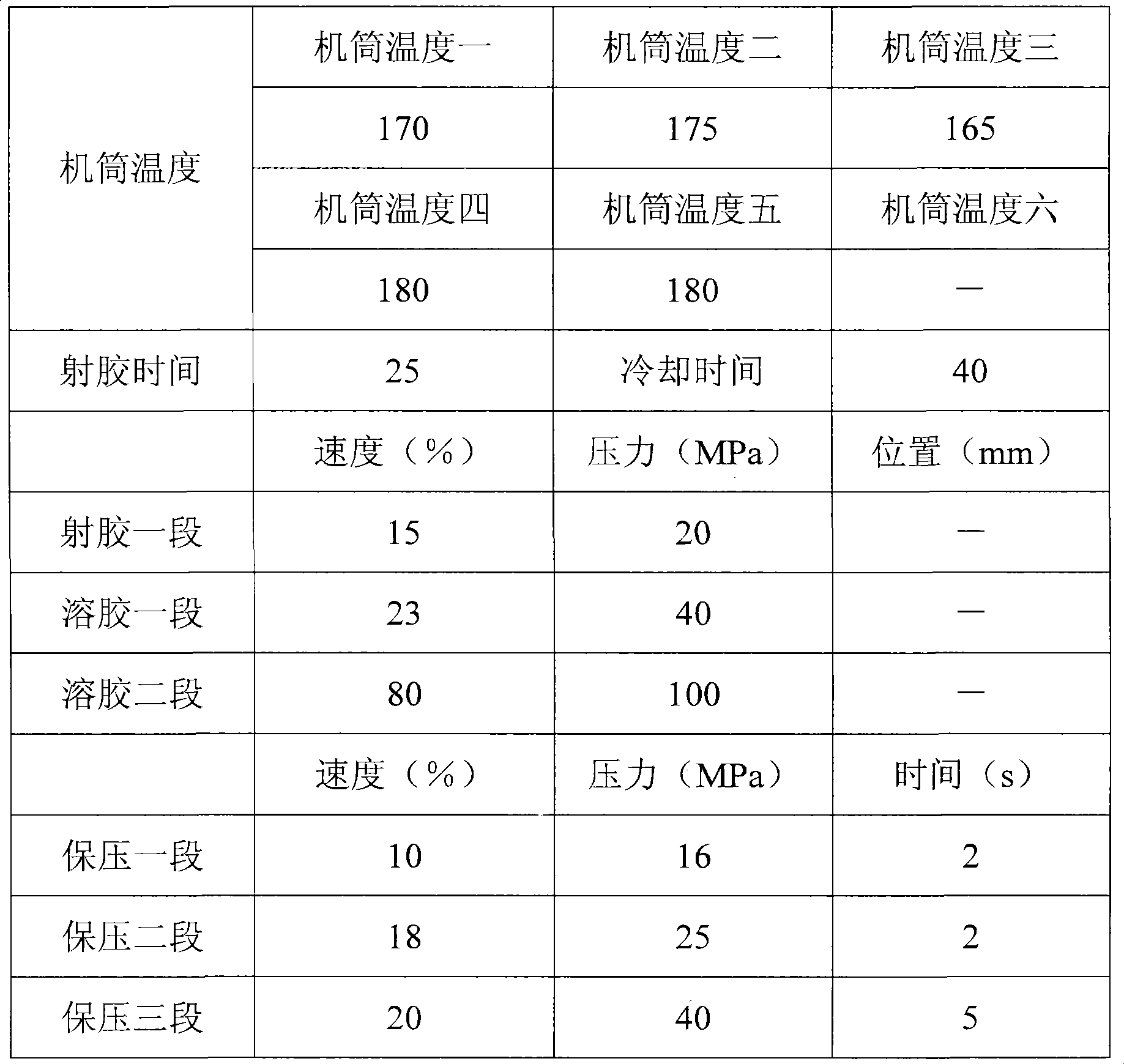

[0060] (3) Prepare mixed ingredients: mix the above-mentioned mixed treatment materials with heat stabilizers, lubricants, processing modifiers, impact modifiers, etc. a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com