Halogen-free flame retardant PC/ABS alloy and preparation method thereof

A technology of alloy and flame retardant, which is applied in the field of halogen-free flame-retardant PC/ABS alloy and its preparation, can solve the problem of low mechanical properties and achieve the effect of excellent mechanical properties and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

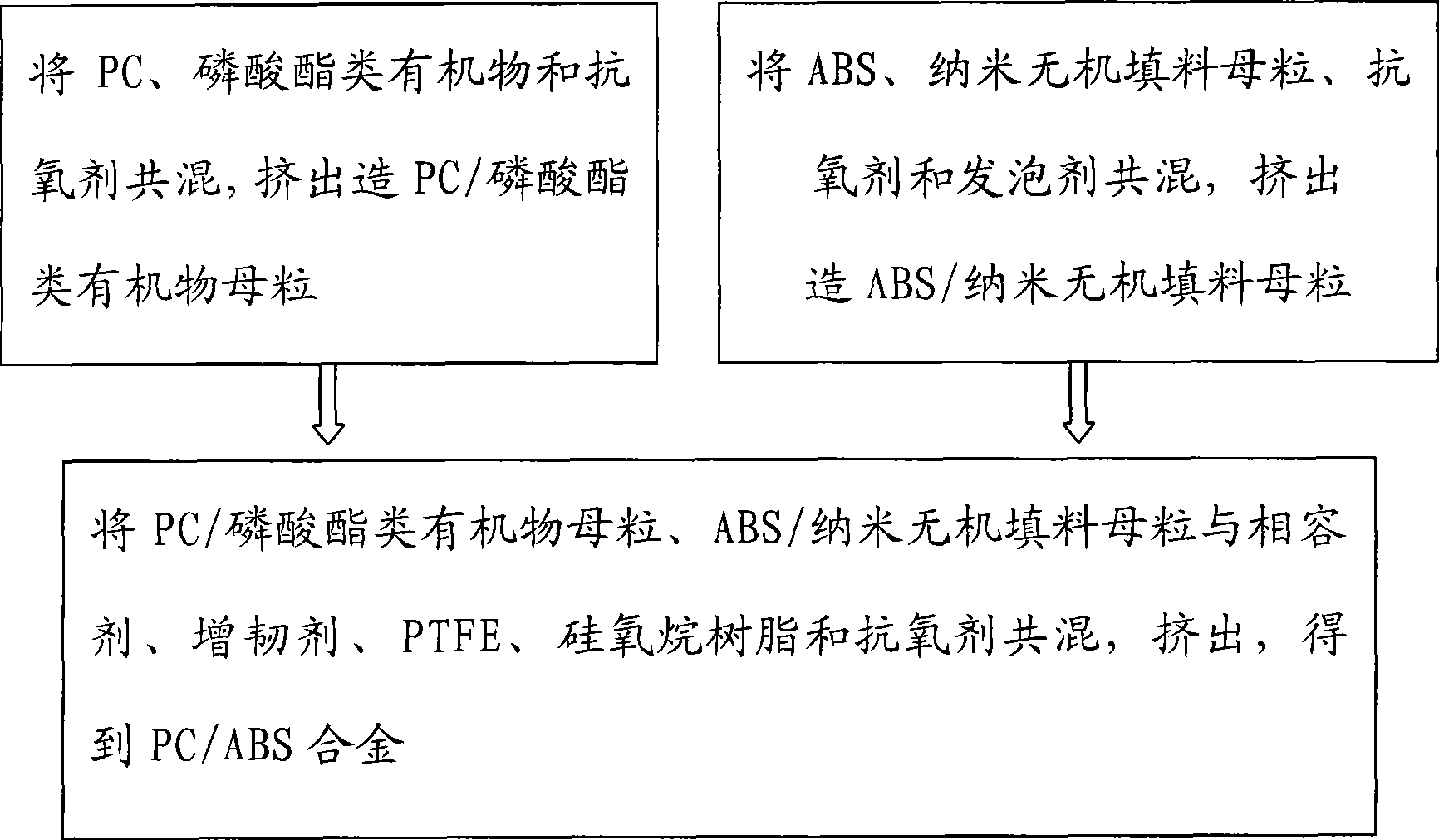

Method used

Image

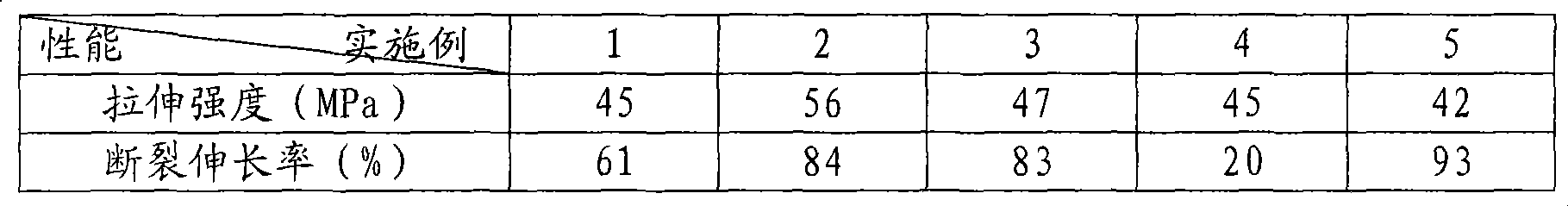

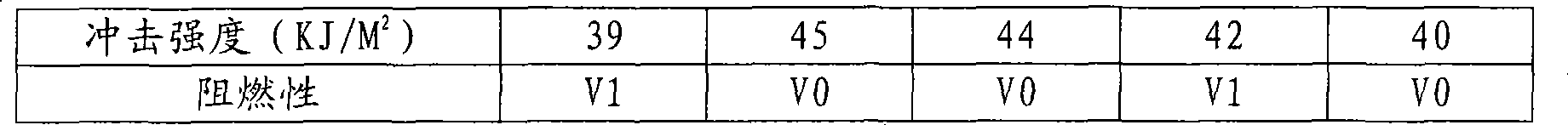

Examples

Embodiment 1

[0033] 1) Preparation of PC / phosphate organic matter masterbatch

[0034] Mix PC and organic phosphates at a ratio of 18.60% by weight of organic phosphates, and then add 0.1 part of antioxidant 1010 and 0.2 part of antioxidant 802 to every 100 parts of PC / organic phosphate mixture After mixing evenly in the mixer, add it to the twin-screw extruder, melt and mix it to make PC / phosphate organic masterbatch, the temperature of the twin-screw extruder is: the temperature of the first zone: 190 ° C, the temperature of the second zone: 210 ° C , The temperature in the third zone: 225°C, the temperature in the fourth zone: 240°C, the temperature in the fifth zone: 230°C, the temperature in the sixth zone: 220°C, the twin-screw speed is 280r / min, and the residence time is 1-2 minutes;

[0035] 2) Preparation of ABS / nano-inorganic filler masterbatch

[0036] 1. ABS and nano-inorganic fillers are mixed according to the ratio of 1.96% by weight of nano-inorganic fillers, and then 0.25 ...

Embodiment 2

[0042] 1) Preparation of PC / phosphate organic matter masterbatch

[0043] Mix PC and organic phosphates at a ratio of 13.46% by weight of organic phosphates, and then add 0.1 part of antioxidant 1010 and 0.2 part of antioxidant 802 to every 100 parts of PC / organic phosphate mixture After mixing evenly in the mixer, add it to the twin-screw extruder, melt and mix to make PC / phosphoric acid ester organic masterbatch, the temperature of the twin-screw extruder is: the temperature of the first zone: 210°C, the temperature of the second zone: 225°C , The temperature in the third zone: 240°C, the temperature in the fourth zone: 255°C, the temperature in the fifth zone: 240°C, the temperature in the sixth zone: 230°C, the twin-screw speed is 400r / min, and the residence time is 1-2 minutes;

[0044] 2) Preparation of ABS / nano-inorganic filler masterbatch

[0045] 1. ABS and nano-inorganic fillers are mixed according to the ratio of 7.41% by weight of nano-inorganic fillers, and then ...

Embodiment 3

[0051] 1) Preparation of PC / phosphate organic matter masterbatch

[0052] Mix PC and organic phosphates at a ratio of 15.73% by weight of organic phosphates, and then add 0.1 part of antioxidant 1010 and 0.2 part of antioxidant 802 to every 100 parts of PC / organic phosphate mixture .After mixing evenly in the mixer, add it to the twin-screw, melt and mix to make PC / phosphate organic masterbatch, the temperature of the twin-screw extruder is: the temperature of the first zone: 200°C, the temperature of the second zone: 220°C, and the third zone Temperature: 235°C, temperature in zone four: 245°C, temperature in zone five: 235°C, temperature in zone six: 225°C, twin-screw speed 340r / min, residence time 1-2 minutes;

[0053] 2) Preparation of ABS / nano-inorganic filler masterbatch

[0054] 1. ABS and nano-inorganic fillers are mixed according to the ratio of 2.44% by weight of nano-inorganic fillers, and then 0.25 parts of antioxidant 1010 and 0.5 parts of antioxidant 802 are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com