Manganese-rich slag electric furnace mounted with condensation lining

A manganese-rich slag and electric furnace technology, applied in the direction of the overall lining, can solve the problems of the furnace lining being easily corroded, short service life, frequent electric furnace maintenance, etc., and achieve the effect of reducing the maintenance probability and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

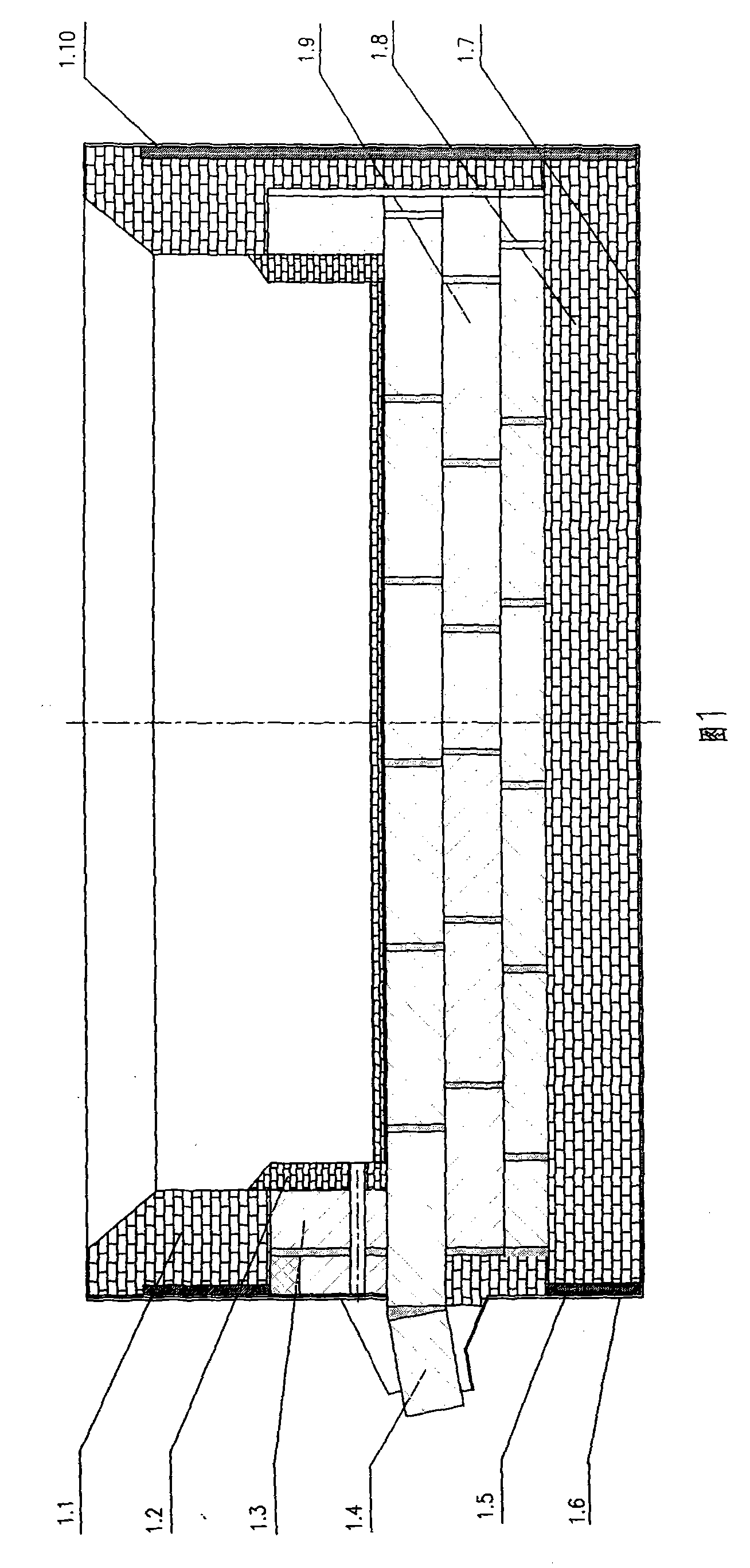

[0024] Embodiment 1: Taking the 18000KVA electric furnace as an example, the specific structure is described as follows:

[0025] 1. Electric furnace parameters:

[0026] Compared with the existing manganese-rich slag electric furnace with the same capacity, the present invention increases the diameter of the furnace shell by +10%, the diameter of the furnace by +12%, the depth of the furnace by +20%, and the diameter of the core circle by +10%.

[0027] Electrode diameter 1100mm

[0028] Furnace shell diameter 12300mm

[0029] Furnace shell height 4900mm

[0030] Furnace diameter 11242mm (including high alumina brick protective layer)

[0031] Hearth depth 3200mm

[0032] Polar garden diameter 3400mm

[0033] 2. Electric furnace cooling:

[0034] After the temperature of the furnace shell reaches 70°C, the furnace shell is sprayed with water, and the bottom of the furnace is ventilated and cooled. The thermal conductivity of the steel plate is 49w / m°C, which can transf...

Embodiment 2

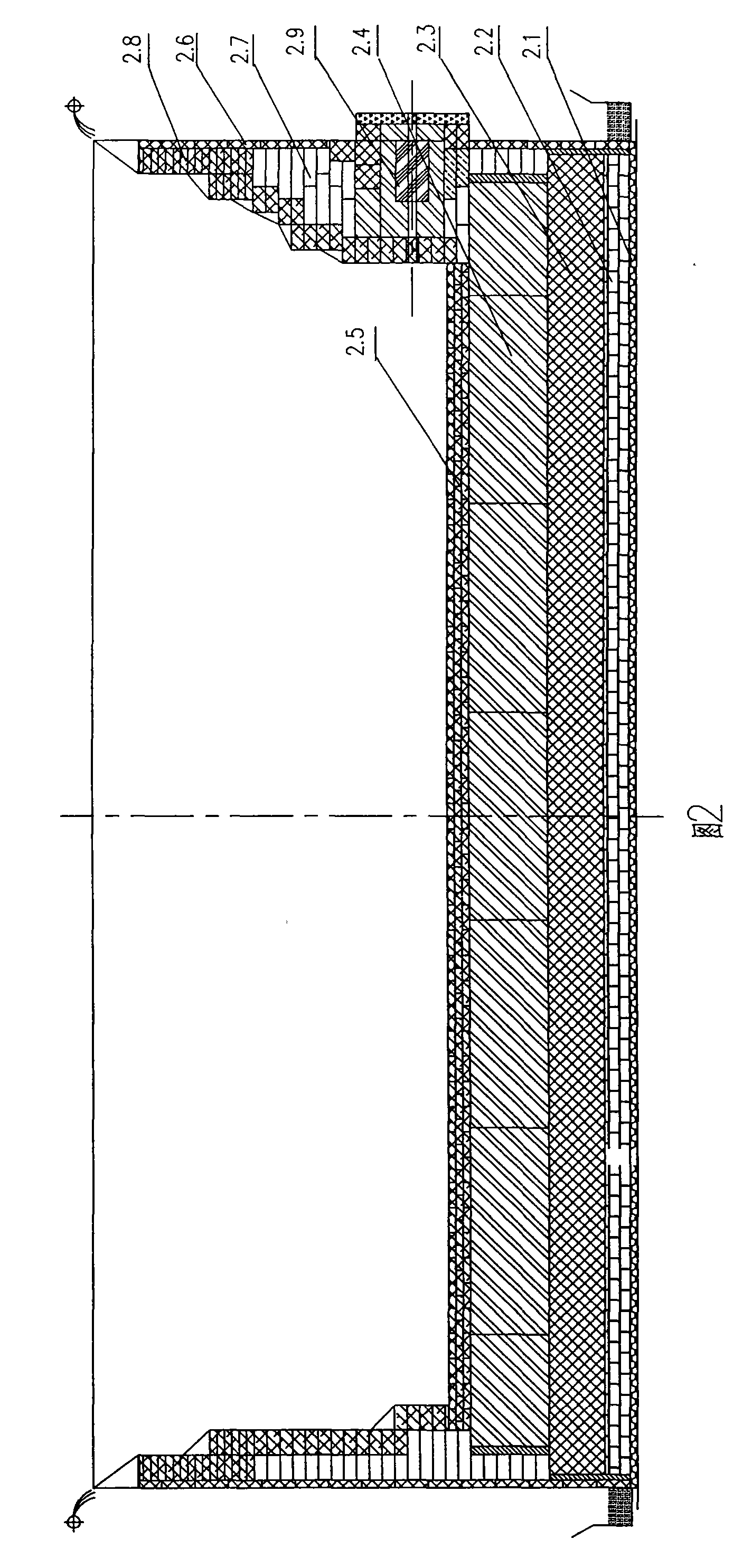

[0056] Example 2: 9000KVA manganese-rich slag electric furnace

[0057] 1. In order to form the condensing furnace lining, the parameters of the selected 9000KVA electric furnace are:

[0058] Electrode diameter 900mm

[0059] Furnace shell diameter 10000mm

[0060] Furnace shell height 4300mm

[0061] Hearth diameter 9402mm

[0062] Hearth depth 2757mm

[0063] Polar garden diameter 2900mm

[0064] 2. The furnace shell is sprayed with water, and the furnace bottom is ventilated and cooled: the air volume of the furnace bottom fan is 50000m 3 / h.

[0065] 3. Open the furnace: Use wood to bake the furnace for a whole day and night to dry the furnace lining and bake it with a low fire in the early stage. Burn slowly. Gradually increase the flame. Electric oven for 3 days, using 63.5 volts. Use the 1st level voltage to send power. Gradually increase the voltage to increase the load until it changes to normal smelting voltage on the fourth day.

[0066] 4. Maintenance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com