Vertebra filling block

A technology of spinal filling block and cushion body, which is applied in spinal implants, medical science, internal bone synthesis, etc., can solve problems such as damage to spinal joints, and achieve the effect of reducing wear consumption, increasing service life, and assembling stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The other objectives, advantages and notable features of the present invention will be described below, and the present invention can be realized after being familiar with the technology and reading the description in the text.

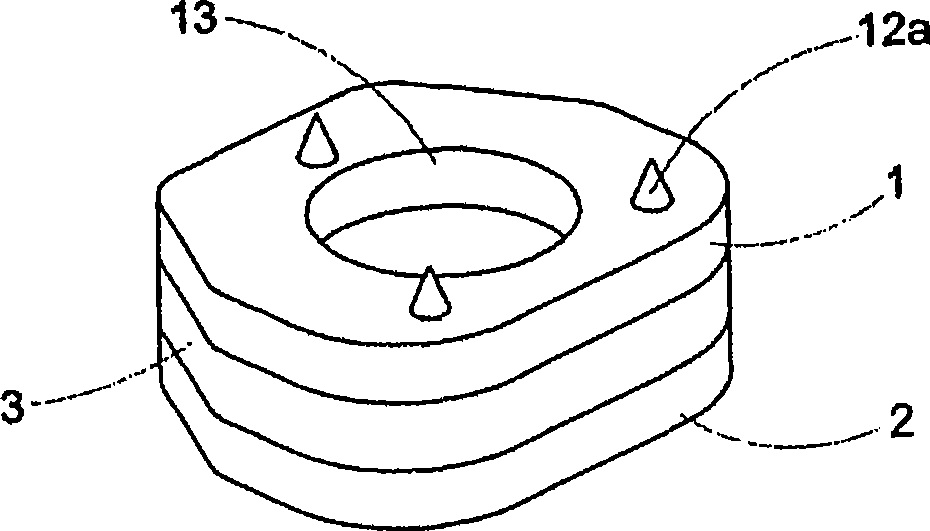

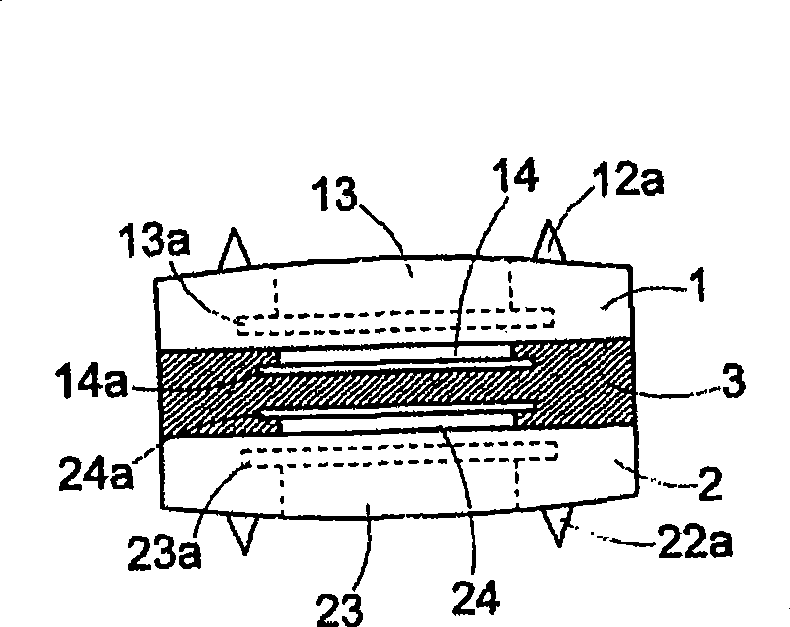

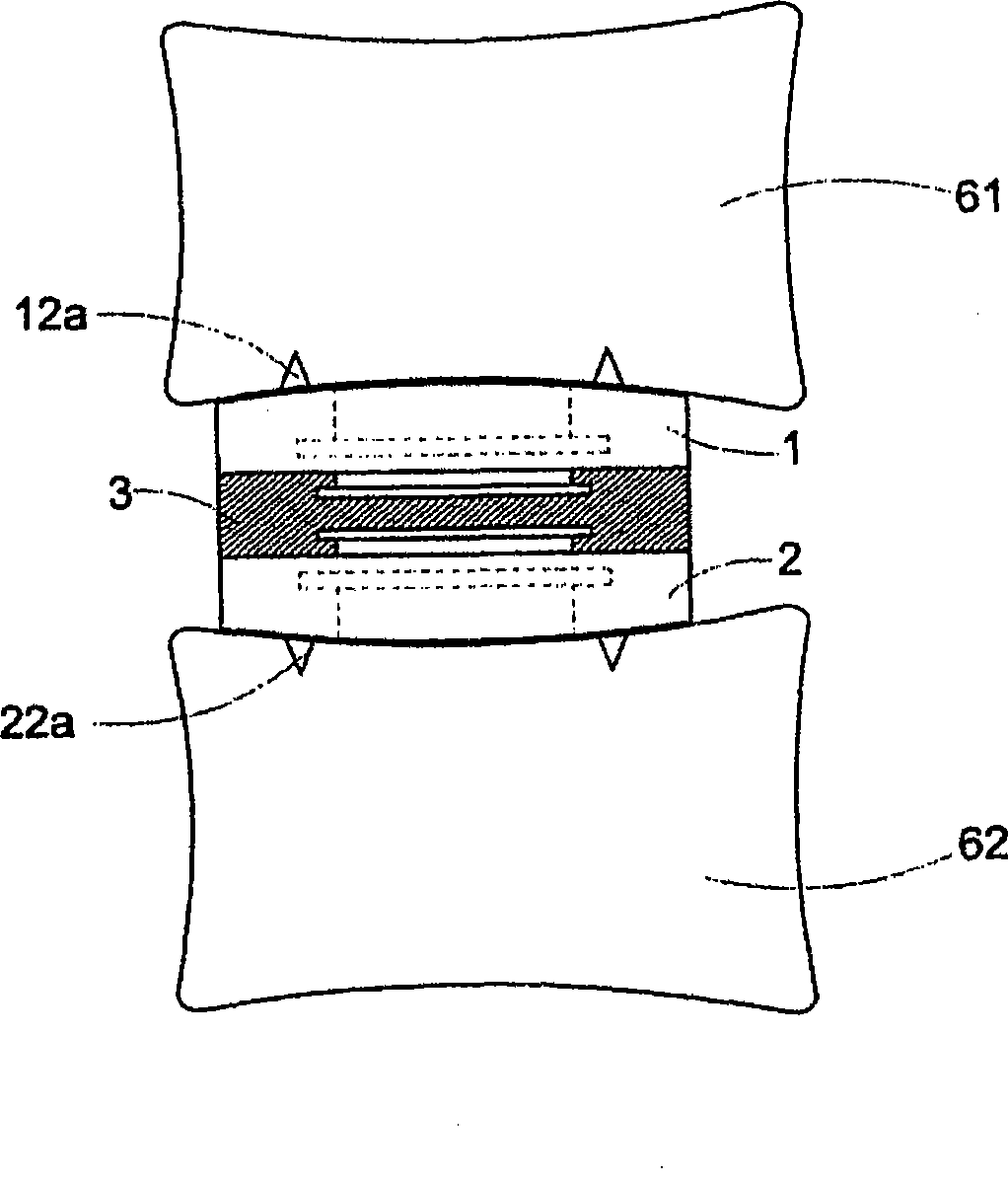

[0030] Please refer to the attached figures, which are preferred embodiments of the spinal filling block of the present invention, and its composition mainly includes an upper cushion body 1, a lower cushion body 2 and an elastic body 3; wherein,

[0031] The upper pad body 1 is made of composite materials (such as carbon fiber, polyether ether ketone, PEEK-polyether ether kefone, etc.) or alloy materials (such as titanium alloy, stainless steel, etc.), so it has good mechanical strength and Chemical resistance, suitable for use between human spines; make the top surface of the pad body a slightly convex arc surface, which can just conform to the concave arc configuration of the bottom end surface of the vertebral block 61 to be installed; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com