Dewatering process of fluorine hydride

A technology of hydrogen fluoride and dehydrating agent, applied in fluorine/hydrogen fluoride and other directions, can solve problems such as cost increase, difficult control, complicated operation, etc., and achieve the effect of improving utilization rate and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

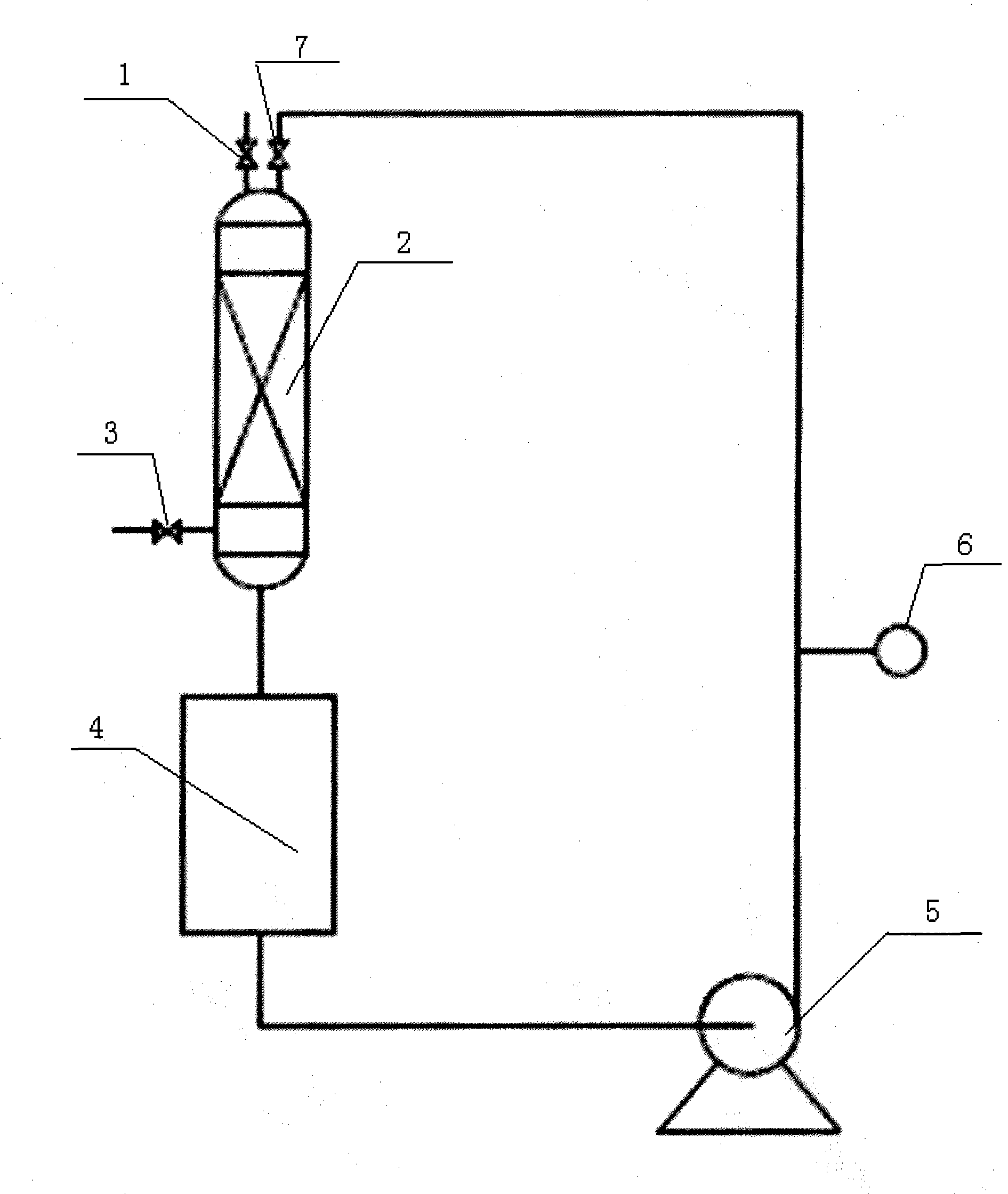

[0020] Such as figure 1 As shown, firstly, under the protection of nitrogen, put 20-30 mesh solid cobalt trifluoride particles into the dehydrating agent container 2, add 50 liters of hydrogen fluoride with a water content of 100 ppm into the hydrogen fluoride container 4, then open the circulation valve 7 and pump Vacuum valve 1 starts the circulation pump 5, the pressure of the control system is lower than the safe design pressure, the linear velocity of hydrogen fluoride liquid flowing in the dehydrating agent container 2 is 0.5 m / s, and the gaseous fluoride generated in this process passes through the vacuum valve 1 Discharge, after 3 hours, take a sample to measure the water content of 50ppm, after 5 hours, 10 hours, and 15 hours, take a sample to detect respectively, the water content is respectively 42ppm, 12ppm, 5ppm, and the sampling inspection can be carried out by the analyzer 6.

[0021] The dehydrating agent CoF used in this embodiment 3 After running for a perio...

Embodiment 2

[0023] Such as figure 1 As shown, first put 20-30 mesh solid manganese tetrafluoride (MnF 4 ) particles, add 35 liters of hydrogen fluoride with a water content of 150ppm in the hydrogen fluoride container 4, then open the circulation valve 7, start the circulation pump 5, the pressure of the control system is lower than the safety design pressure, and the hydrogen fluoride liquid flows in the dehydrating agent container 2. The speed is 0.5 m / s. The gaseous fluoride generated during this process is discharged through the vacuum valve 1. After 3 hours, the water content is 80ppm, and after 5.5 hours, 8 hours, and 15 hours, the water content is 45ppm. , 15ppm, 7.5ppm, the sampling test can be carried out by the analyzer 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com