Method for purifying and ingot casting multi-temperature zones silicon material and apparatus thereof

A silicon material, multi-temperature zone technology, applied in the direction of polycrystalline material growth, post-processing devices, chemical instruments and methods, etc., can solve problems such as power consumption, avoid cooling and reheating, good directional solidification effect, high energy The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

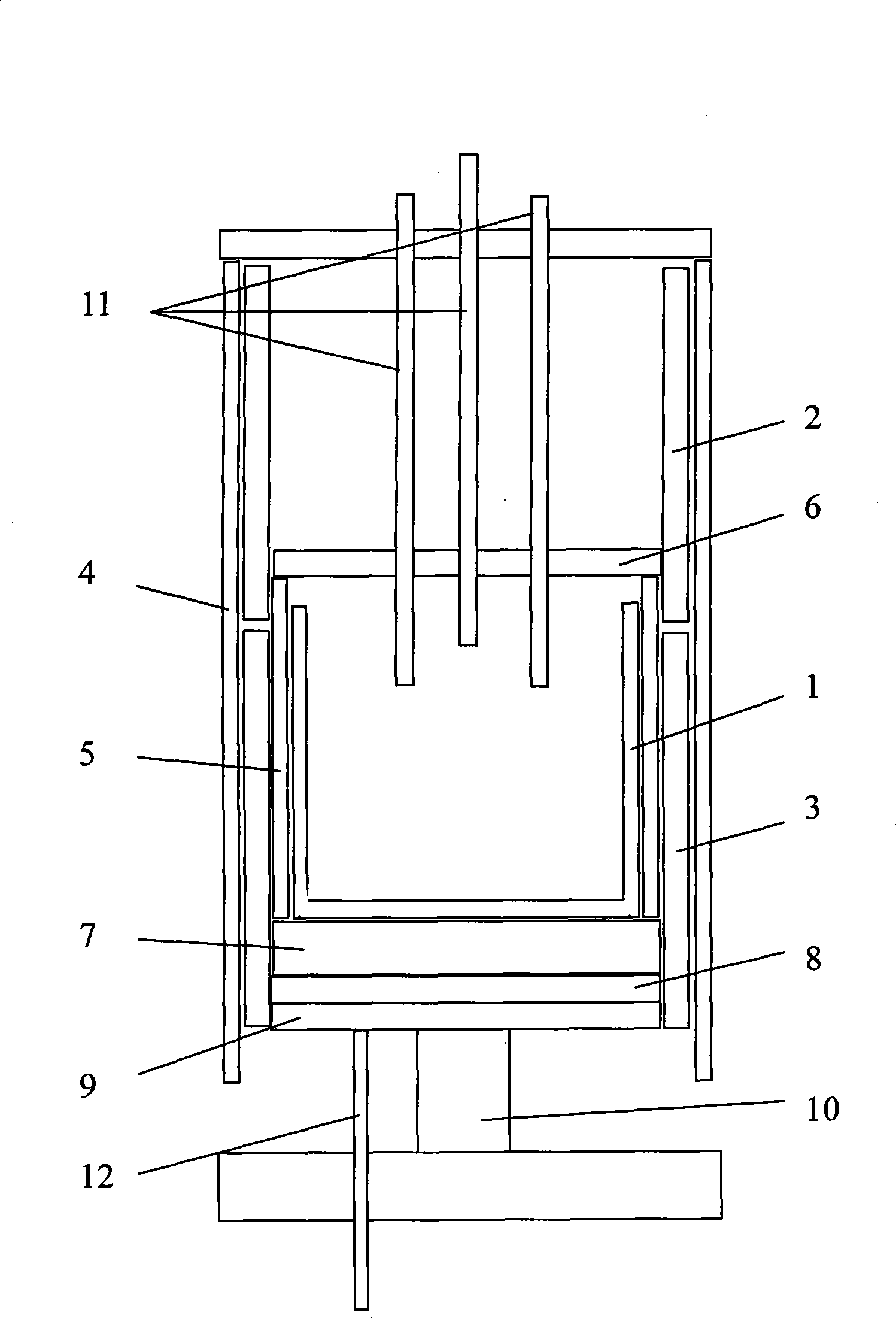

[0024] Firstly, the material is loaded, using a quartz crucible 1 of 720mm x 720mm x 420mm, and loading 270 kg of silicon material and about 3 kg of slagging agent composed of CaO, MgO, SiO2, FeO, Na2O, BaO, and CaF2. After the sheath 5 of the crucible 1 is installed, the crucible 1 is moved up to the induction heating area through the lifting device 10, and then the power supply of the induction heater 2 is energized to heat the crucible 1 after vacuuming.

[0025] At 300 degrees, keep warm for half an hour, then rise to 900 degrees, and keep warm for another half an hour.

[0026] Then heat up to 1390 degrees and keep warm for half an hour.

[0027] Then start to heat up to heat up and melt the silicon material in the crucible 1 . After melting, continue to heat up to 1650 degrees and keep the temperature for 2 hours. At this time, impurities with high saturated vapor pressure in the silicon material are volatilized. At the end of the heat preservation, the reaction gas i...

Embodiment 2

[0033] Carry out feeding first, adopt the quartz crucible 1 of 720mm x 720mm x 420mm, put into 160 kilograms of silicon materials and about 2 kilograms of the slagging agent that is composed of CaO, MgO, SiO2 and FeO. After the sheath 5 of the crucible 1 is installed, the crucible 1 is moved up to the induction heating area through the lifting device 10, and then the power supply of the induction heater 2 is energized to heat the crucible 1 after vacuuming.

[0034] At 200 degrees, keep warm for 0.5 hours, then rise to 800 degrees, and keep warm for 0.3 hours.

[0035] Then heat up to 1350 degrees, and keep warm for 0.5 hours.

[0036] Then start to heat up to heat up and melt the silicon material in the crucible 1 . After melting, continue to heat up to 1600 degrees, and keep it warm for 1 hour. At this time, impurities with high saturated vapor pressure in the silicon material are volatilized. At the end of the heat preservation, the reaction gas introduction pipe 11 is l...

Embodiment 3

[0042] Carry out feeding first, adopt the quartz crucible 1 of 720mm x 720mm x 420mm, load 400 kilograms of silicon material and about 4 kilograms of slagging agent composed of CaO, Na2O, BaO and CaF2. After the sheath 5 of the crucible 1 is installed, the crucible 1 is moved up to the induction heating area through the lifting device 10, and then the power supply of the induction heater 2 is energized to heat the crucible 1 after vacuuming.

[0043] At 400 degrees, keep warm for 1 hour, then rise to 1000 degrees, and keep warm for 0.7 hours.

[0044] Then heat up to 1430 degrees, and keep warm for 2 hours.

[0045] Then start to heat up to heat up and melt the silicon material in the crucible 1 . After melting, continue to heat up to 1700 degrees and keep the temperature for 3 hours. At this time, impurities with high saturated vapor pressure in the silicon material are volatilized. When the heat preservation is finished, the reaction gas introduction pipe 11 is lowered, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com