Method for removing organic in water solution by using acroleic acid macroporous adsorption resin

A technology of pore adsorption and acrylic acid, which is applied in the field of water treatment method manufacturing, can solve the problems of insignificant adsorption effect of macromolecular organic matter humic acid and fulvic acid, difficulty in removable ion exchange, loss of ion exchange function, etc., and achieve good water quality , High removal rate of organic matter, good water reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

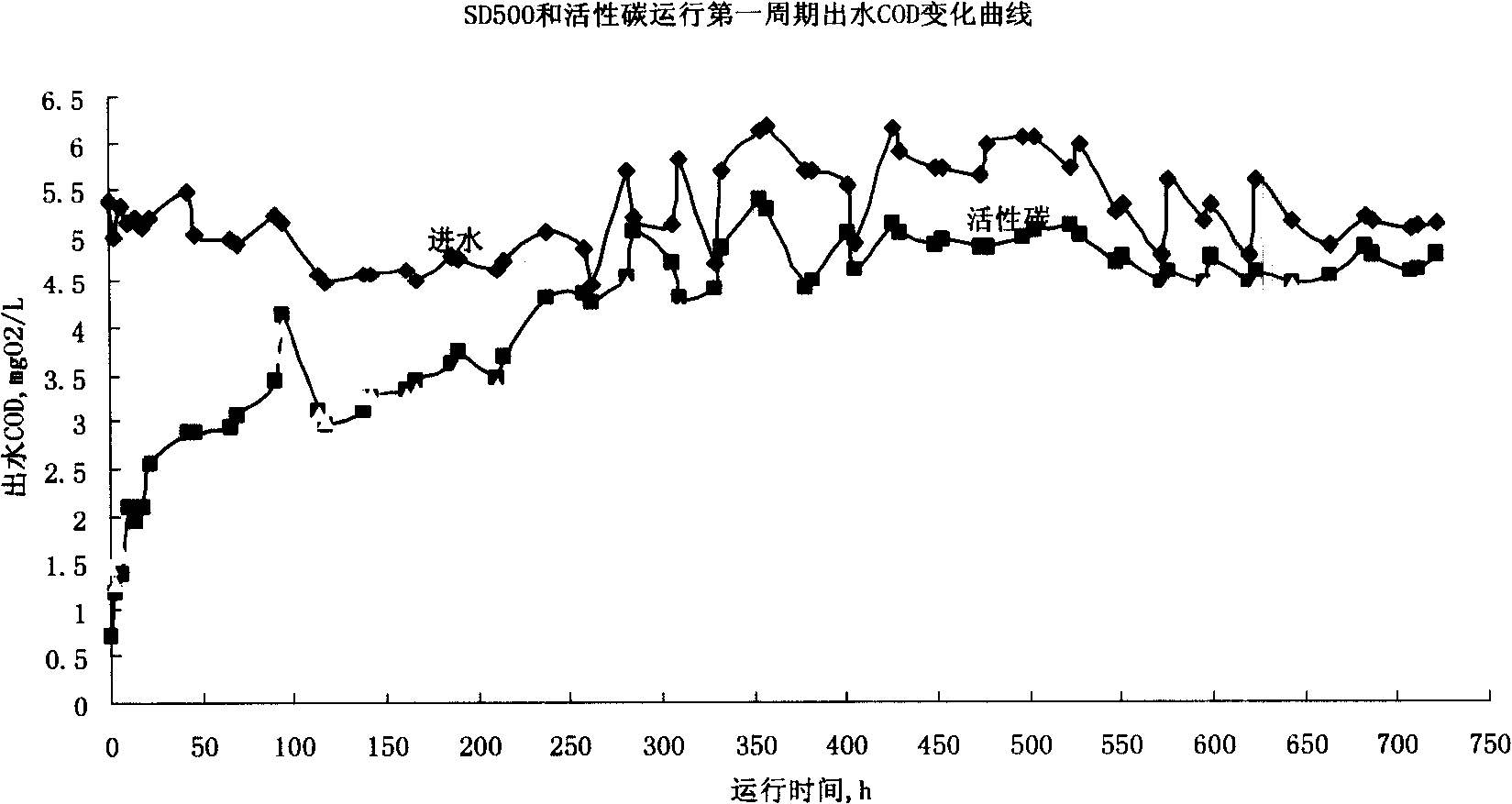

[0032] Figure 15 It is the COD change curve of the effluent in the third cycle of activated carbon and acrylic acid macroporous adsorption resin.

[0033] Indicator name

indicators

Exterior

milky white

the skeleton

Acrylic

Factory type

Chlorine type

Moisture content%

65~75

[0034] Volume full exchange capacity mmol / ml

≥0.8

Wet true density g / ml

1.03~1.10

Wet density g / ml

0.65~0.72

range granularity %

(0.315~1.25mm)≥95

coefficient of uniformity

≤1.60

Effective particle size mm

0.400~0.700

Penetration spherical rate%

≥90%

Specific surface area m 2 / g

500~2000

Pore volumeml / g

≥0.65

[0035] Figure 16 It is activated carbon and acrylic acid macroporous adsorption resin to run backwash water COD Mn and E 260 Change curve comparison chart.

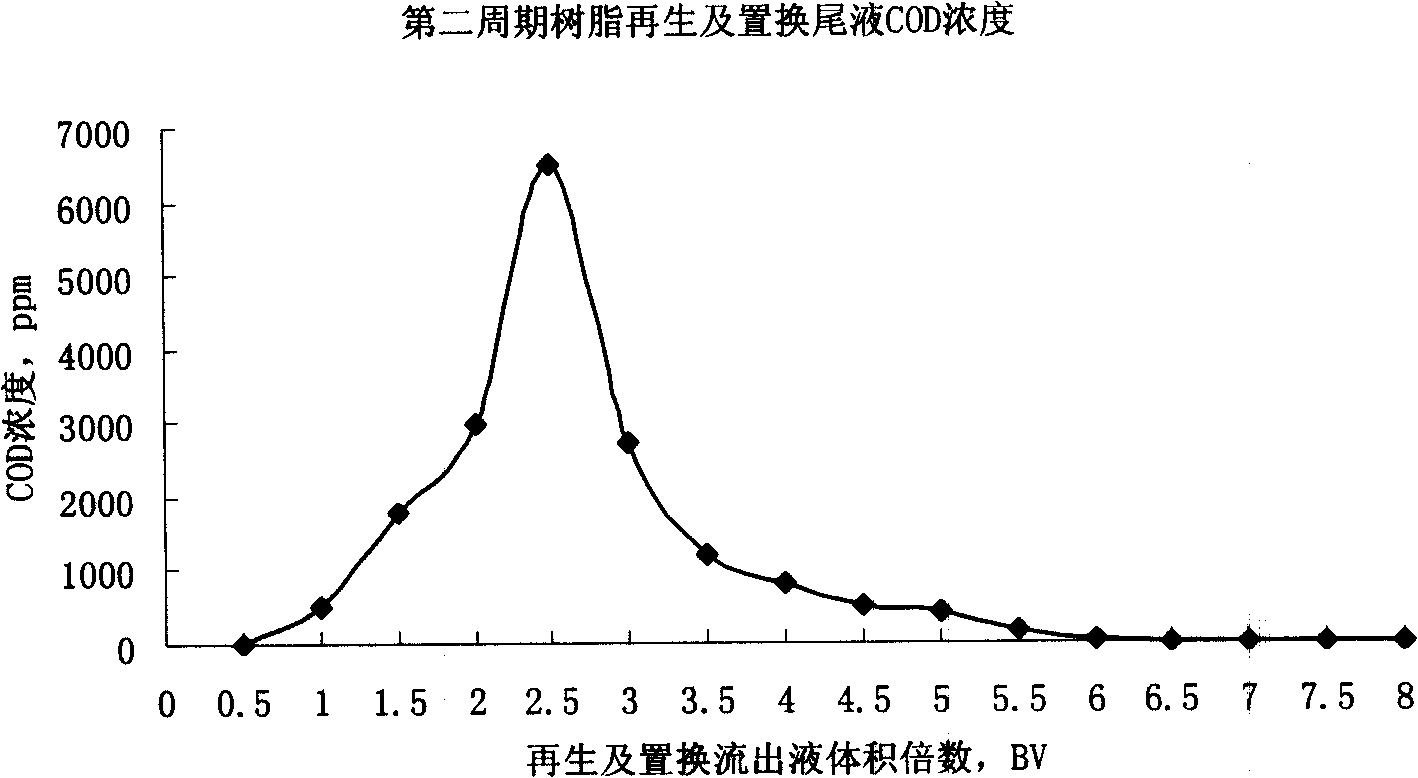

[0036] Figure 17 Resin regeneration and replacement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com