Steel slag ultra-sulphate cement and preparation method thereof

A technology of super sulfate cement and sulfate, which is applied in the field of cement materials, can solve the problem that super sulfate cement has no relevant patents, etc., and achieve the effect of saving stockpiling land, saving resources, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

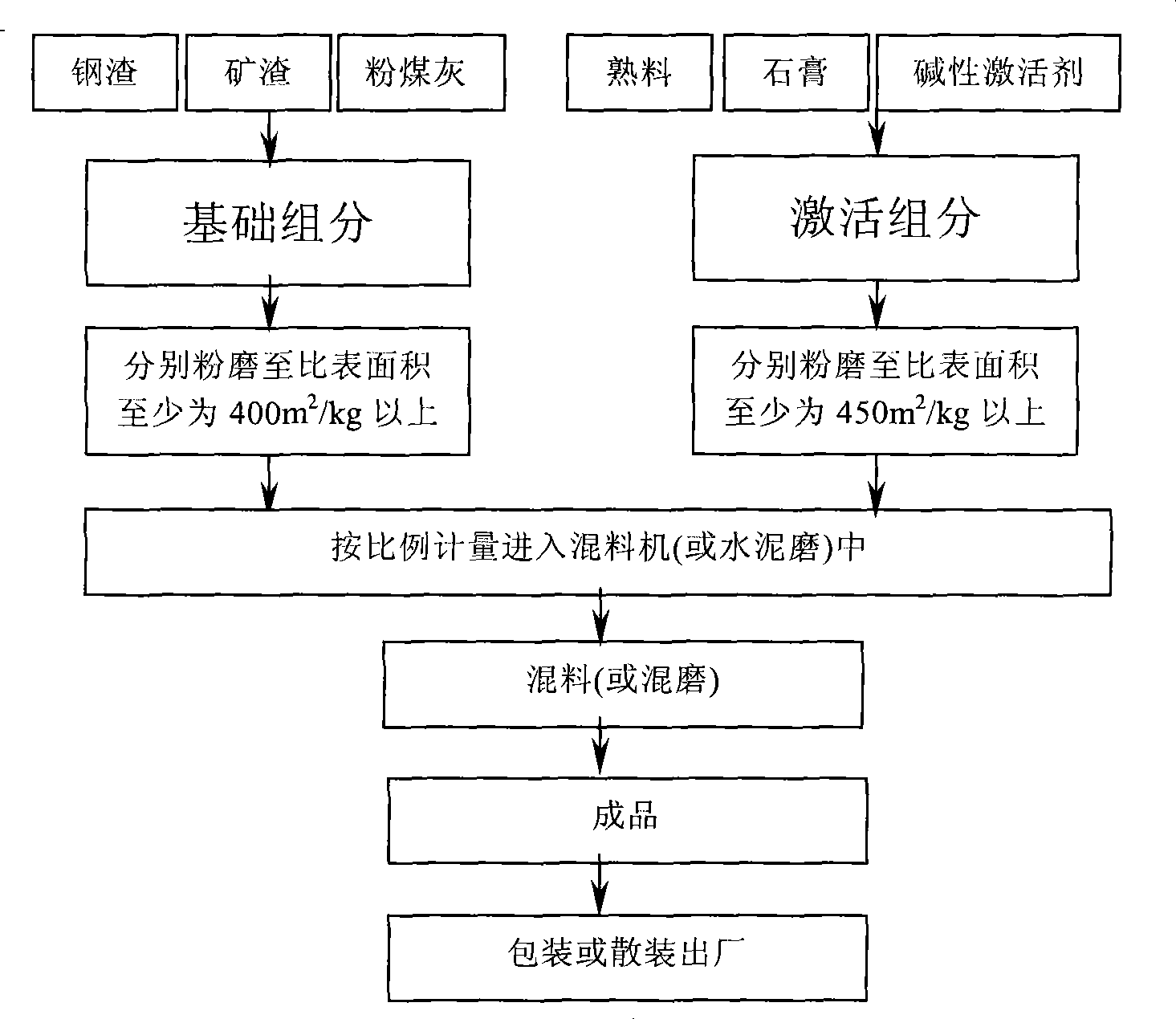

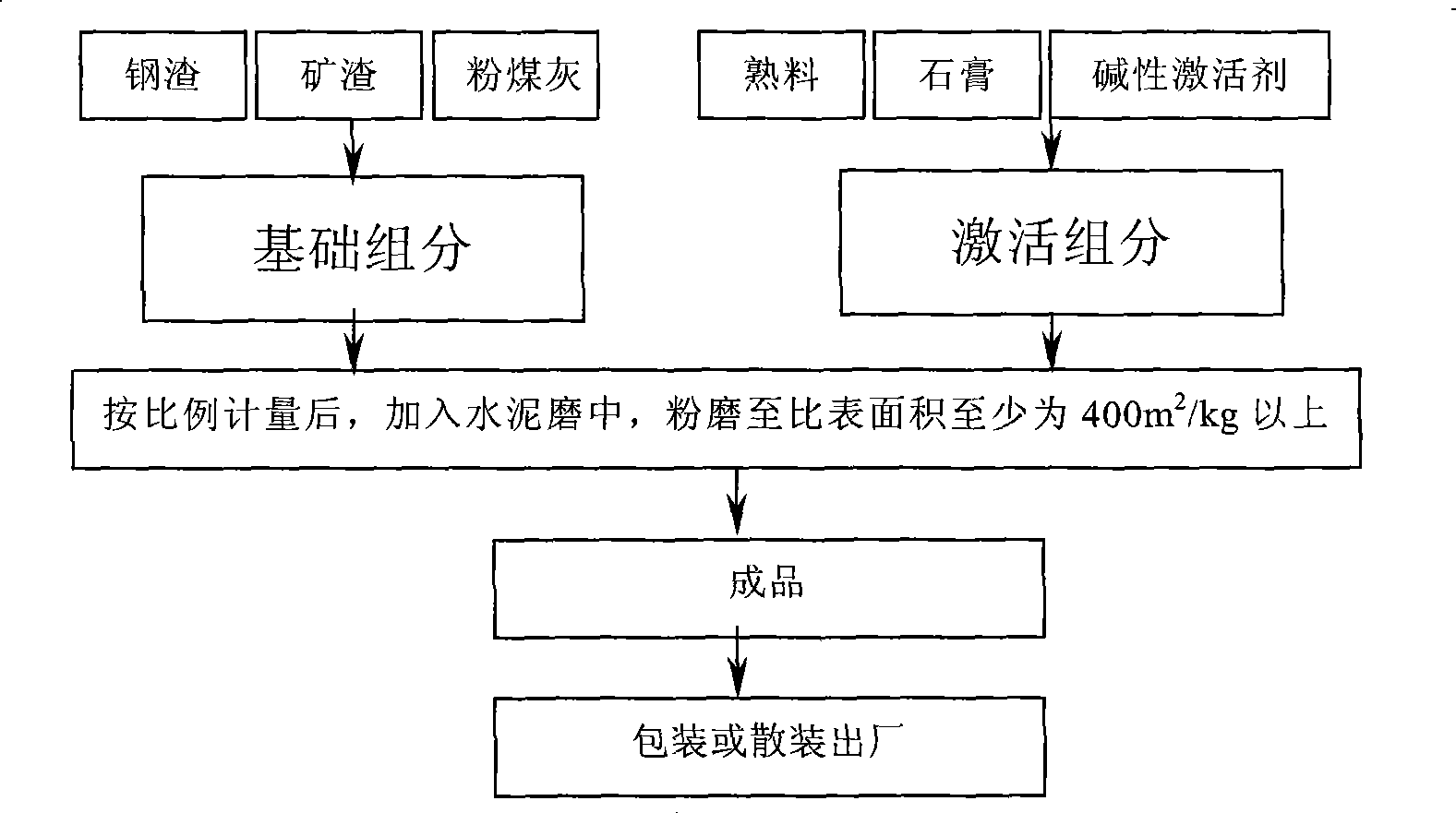

Method used

Image

Examples

Embodiment 1

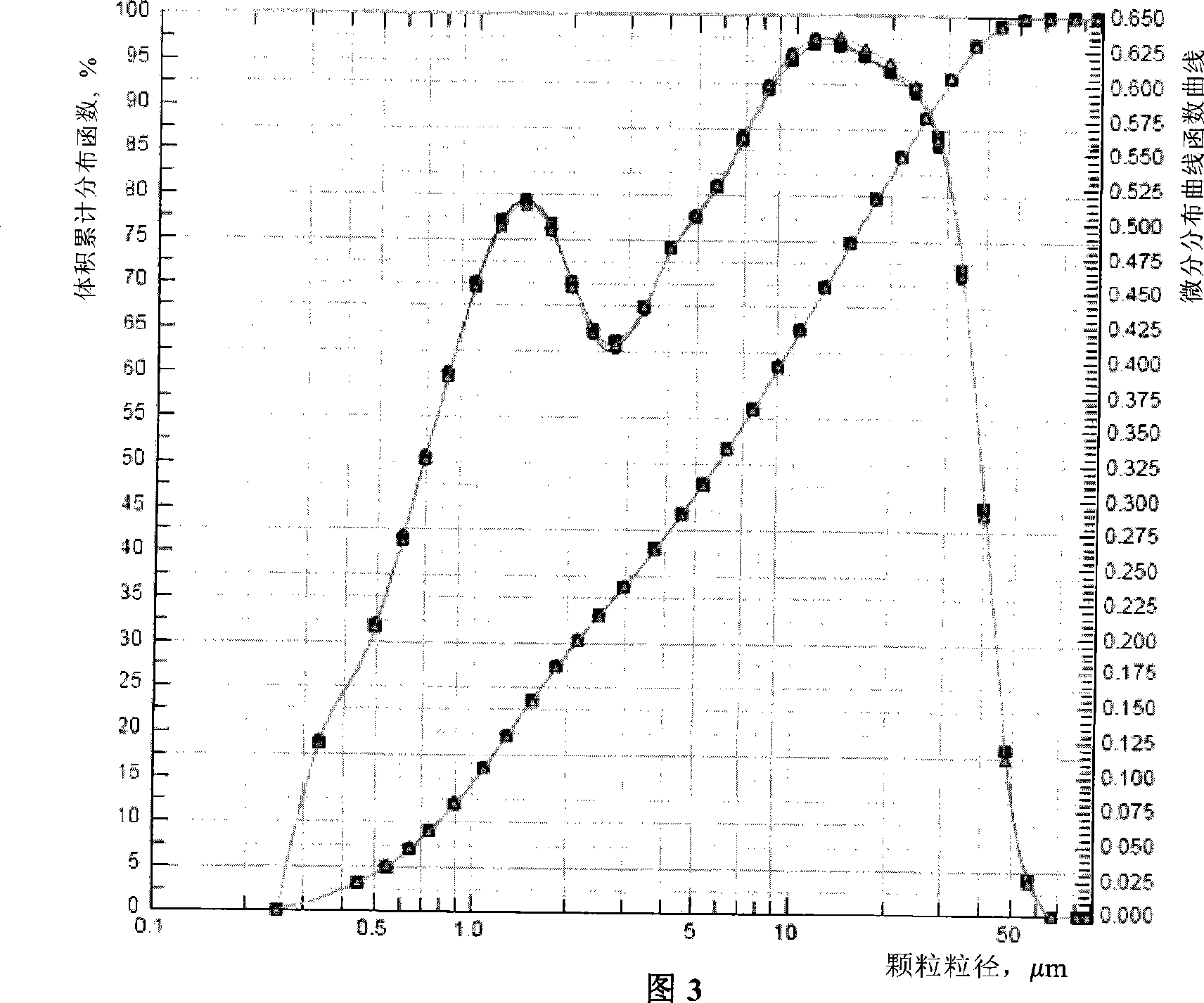

[0036] Embodiment 1: first steel slag, slag and clinker are ground until the specific surface area is at least 450m 2 / Kg, the specific surface area of gypsum is at least 500m 2 / Kg, then measure and weigh according to the proportion of Table 2 formula 1 (wherein the steel slag dosage reaches 40%), each raw material is fully mixed in the forced mixer, and the unloading material is the prepared new steel slag super sulfate cement . The chemical composition analysis of the super sulfate cement is shown in Table 3. Remove the alkaline activator part (0.7% alkaline activator) in formula 1, the particle size distribution curve of the remaining raw material components is shown in Figure 3. The particle size distribution curve is a summary of the results of three parallel samples, and has good statistical regularity. The test results of physical and mechanical properties of the corresponding cement are shown in Table 4. From the performance index of formula 1 in Table 4, it can...

Embodiment 2

[0037] Embodiment 2: earlier raw materials such as steel slag, slag, clinker and gypsum are weighed according to the ratio of Table 2 formula 2 (wherein the amount of steel slag reaches 40%), and then fully ground in the cement mill, the obtained steel slag super The specific surface area of sulfate cement is 484m 2 / Kg, the chemical composition analysis of the super sulfate cement is also shown in Table 3. Figure 3 shows the particle size distribution curves of the remaining raw material components after removing the alkaline activator part (2% alkaline activator) in formula 2. The particle size distribution curve is a summary of the results of three parallel samples, and has good statistical regularity. In Fig. 3, the abscissa is the particle size, the left ordinate is the cumulative volume distribution function, and the right ordinate is the differential distribution curve function curve. The particle size distribution test instrument is a fully automatic dry-wet two-in...

Embodiment 3

[0039] Embodiment 3: first steel slag, fly ash, slag and clinker are ground until the specific surface area is at least 450m 2 / Kg, the specific surface area of gypsum is at least 500m 2 / Kg, then measure and weigh according to the ratio of Table 2 formula 3 (wherein the steel slag dosage reaches 40%), then fully grind in the cement mill to make steel slag super sulfate cement. The chemical composition analysis of the super sulfate cement is shown in Table 3 formula 3, except the alkaline activator part (0.7% alkaline activator) in the formula, the particle size distribution curve of the remaining raw material components is shown in Figure 4. The particle size distribution curve is a summary of the results of three parallel samples, and has good statistical regularity. The test results of physical and mechanical properties of the corresponding cement are shown in Table 4. It can be seen from Table 4 that the various indicators of the steel slag super sulfate cement also me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com