Gas well water blocking damage treating agent

A technology for treating agent and well water, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced water lock damage, difficult flowback of self-absorbed water, reduced capillary radius, etc., and achieves compatibility. Good, reduce water lock damage, reduce the effect of self-priming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: According to the weight percentage, add 75.5% distilled water to the reaction kettle, then add 15% main agent 2,3-epoxypropyltrimethylammonium chloride, stir for 15min; heat up to 35°C, then add 4.0% Nonionic surfactant octylphenol polyoxyethylene ether, add 0.5% SR18Y fluorocarbon surfactant produced by Shaanxi Senrui Technology Co., Ltd., stir for 10 minutes; finally add 5.0% cationic surfactant double 8 / 10 alkyl dimethyl ammonium bromide, and stirred for 10 minutes to obtain a gas well water lock treatment agent.

Embodiment 2

[0026] Example 2: By weight percentage, add 64.2% distilled water to the reactor, add 20% main agent 2,3-epoxypropyltrimethylammonium chloride, stir for 20min; heat up to 40°C, then add 7.0% non- Ionic surfactant dodecylphenol polyoxyethylene ether, add 0.8% SR18Y fluorocarbon surfactant produced by Shaanxi Senrui Technology Co., Ltd., stir for 15 minutes; then add 8.0% cationic surfactant double 8 / 10 alkyl di Methyl ammonium bromide, stirred for 15 minutes to obtain a gas well water lock treatment agent.

Embodiment 3

[0027] Example 3: According to the weight percentage, add 70% distilled water to the reaction kettle, add 18% main agent 2,3-epoxypropyltrimethylammonium chloride, stir for 20min; heat up to 40°C, add 5.4% non-ionic Surfactant octylphenol polyoxyethylene ether, add 0.6% SR18Y fluorocarbon surfactant produced by Shaanxi Senrui Technology Co., Ltd., stir for 10 minutes; add 6.0% cationic surfactant tetradecyldimethylbenzyl ammonium chloride , and stirred for 15 minutes to obtain a gas well water lock treatment agent.

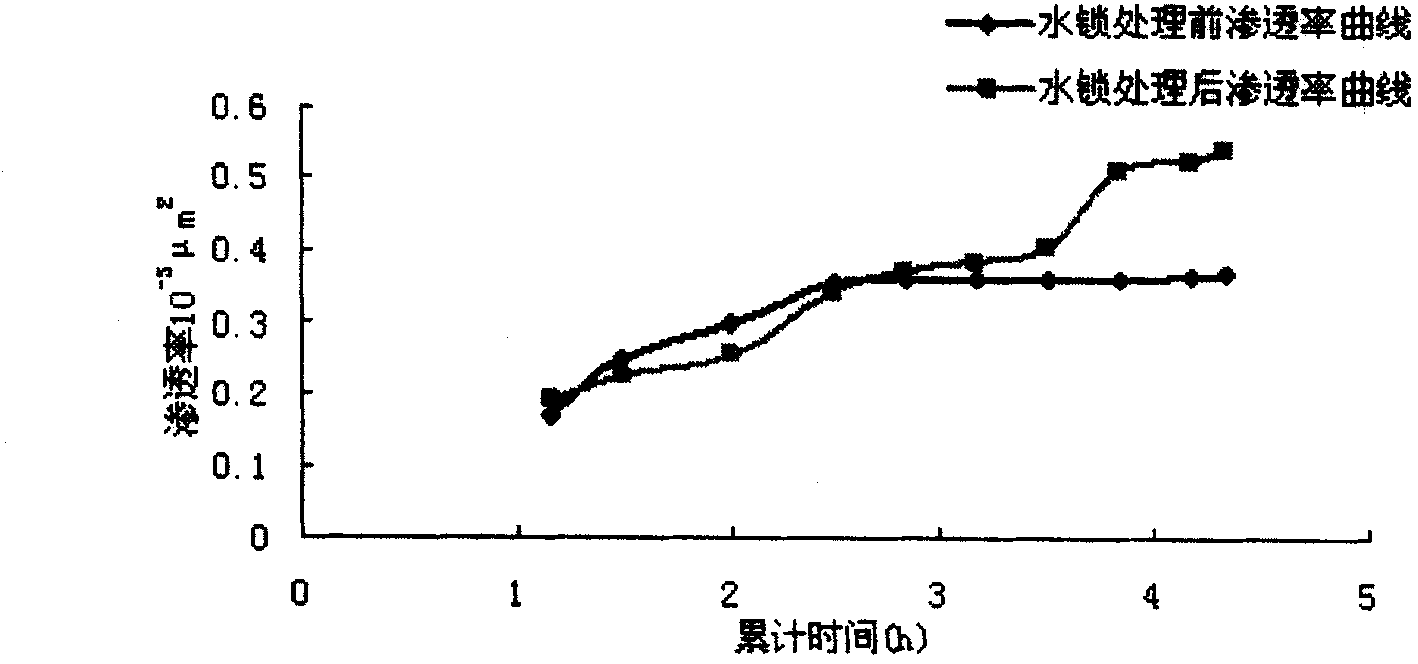

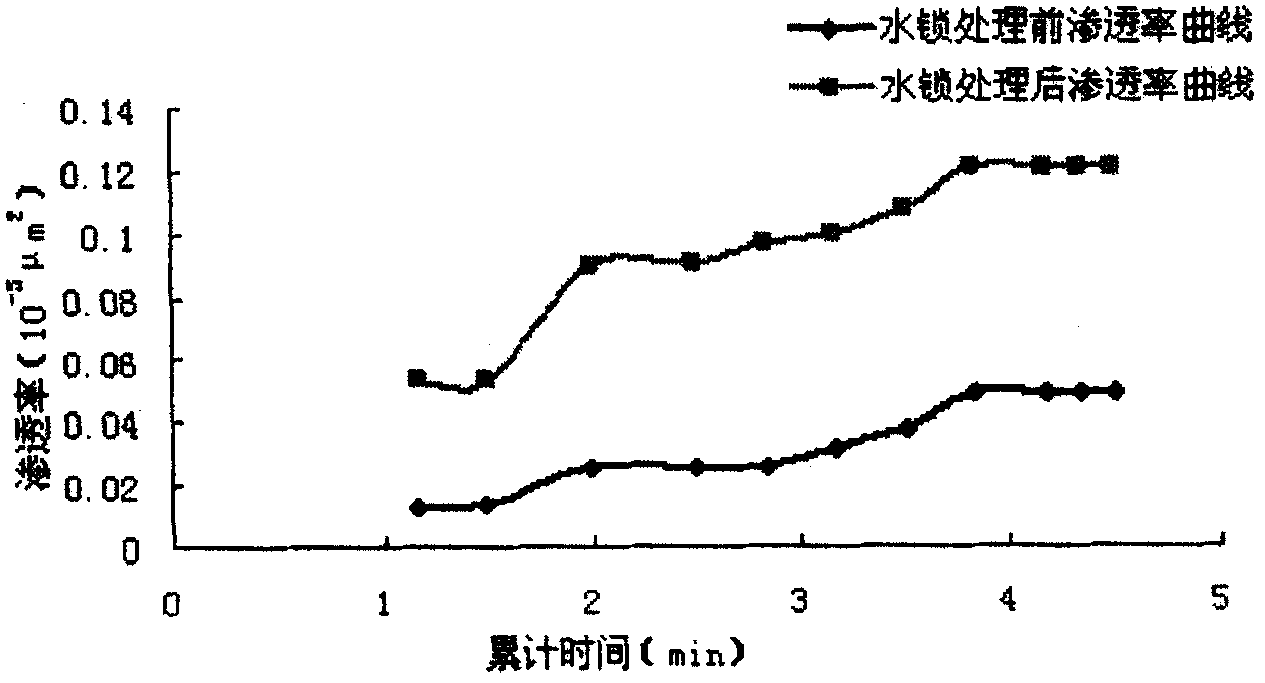

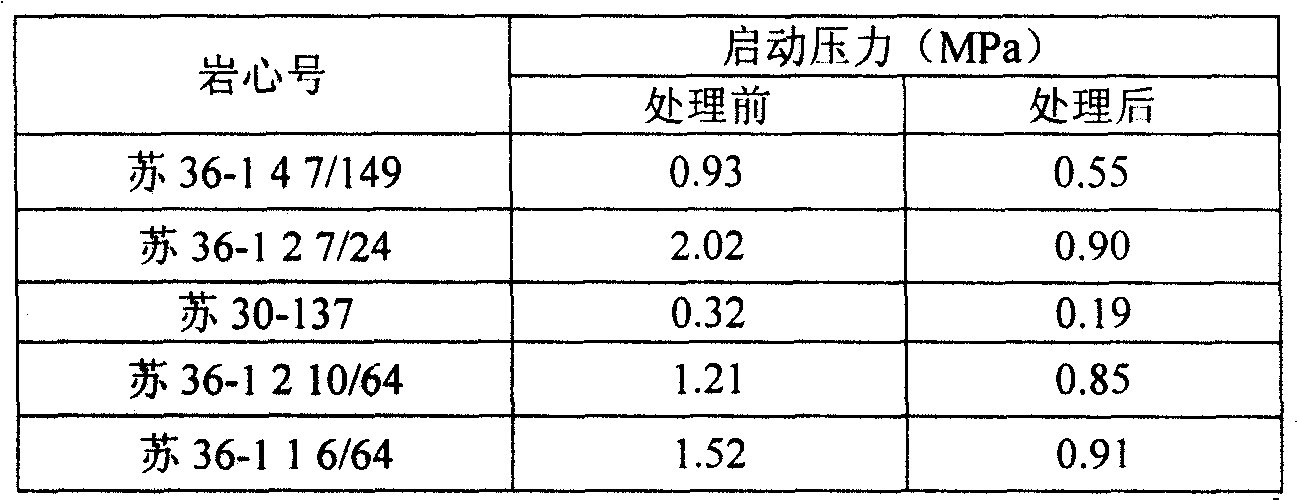

[0028] In the same block test, the conventional water-based fracturing fluid system was used for fracturing reconstruction in the early stage, the flowback period was long, and the single-layer unobstructed flow rate was 0-2000 cubic meters per day, which could not reach the industrial air flow. After the field test of the lock damage treatment agent, the flowback time was shortened by 62 hours, and the unimpeded flow rate of a single layer was 5,000 m3 / day, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com