Creeping agent for pearlite type vermicular cast iron member

A technology of vermicular graphite cast iron and vermicularizing agent, which is applied in the field of vermicularizing agent for cast iron, and can solve the problems of insufficiency and ferritization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

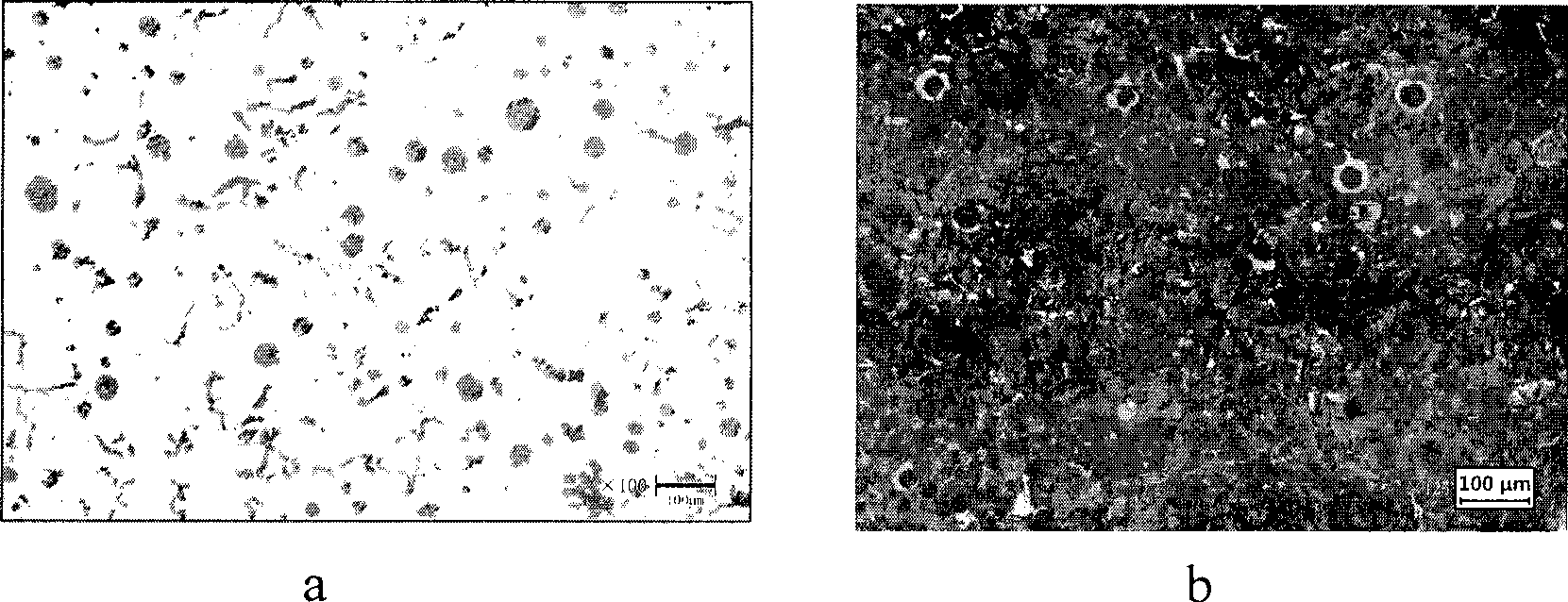

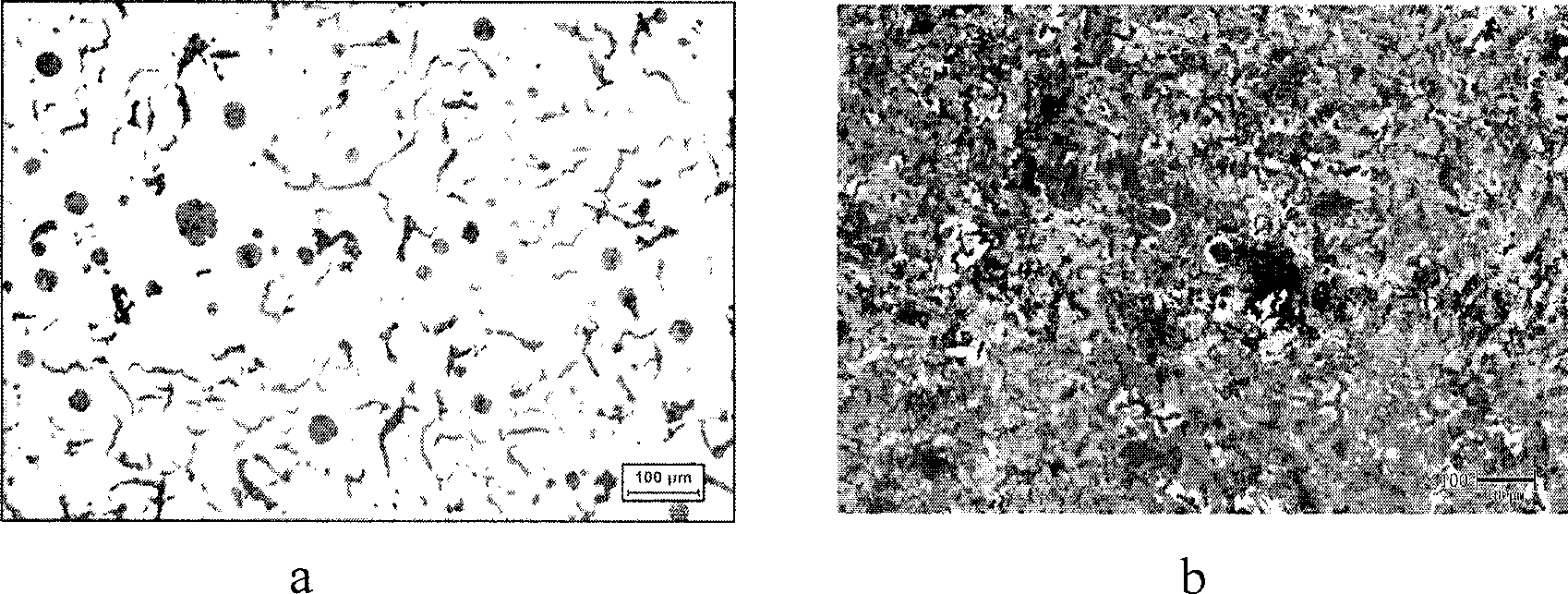

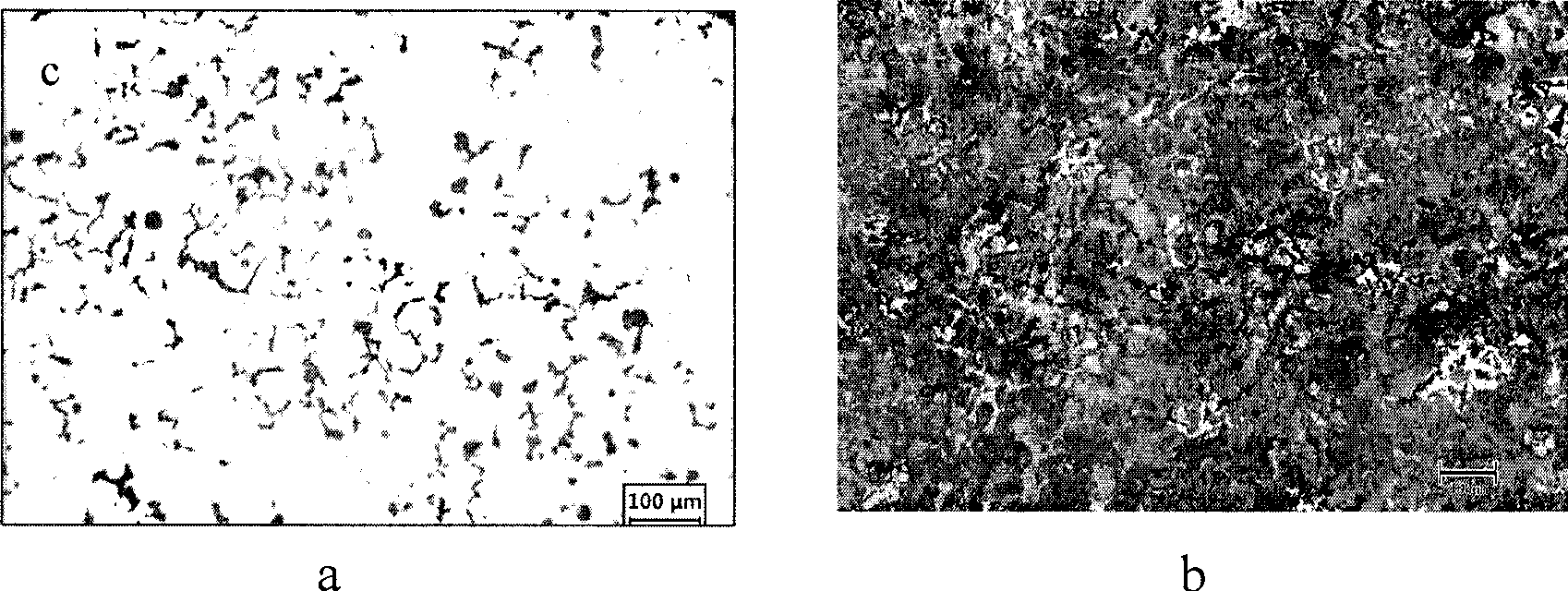

Image

Examples

Embodiment Construction

[0016] The vermicular agent in the following examples is specially used to produce high-power diesel engine piston ring-like vermicular graphite cast iron, which requires high wear resistance, high corrosion resistance, and relatively high mechanical properties.

[0017] In the embodiment, the vermicular agent is formed by smelting rare earth ferrosilicon alloy, metal magnesium ingot, ferrosilicon, ferrophosphorus, aluminum ingot, electrolytic copper, and steel scrap.

[0018] The composition of molten iron before vermicular agent treatment is as follows:

[0019]

[0020] The following table is the percentage by weight of each component of the vermicular agent of each embodiment:

[0021] Example RE% Mg% Si% A1???% P% Cu% Fe 1 10 8 40 1 10 15 margin 2 15 4 50 2 12 20 margin 3 20 2 45 2 10 30 margin 4 15 6 35 1 10 20 margin 5 30 7 45 3 15 15 margin

[0022] The particle size of the vermic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com