Electrochemical tongs for developing protein molecule electronic device and method for producing the same

An electronic device and electrochemical technology, applied in the structural field of electrochemical tweezers, can solve the problems of inability to develop high-speed response capability, protein is not easily deformed, protein deformation and denaturation, etc., and achieves easy control of manufacturing conditions, simple and cheap instruments, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

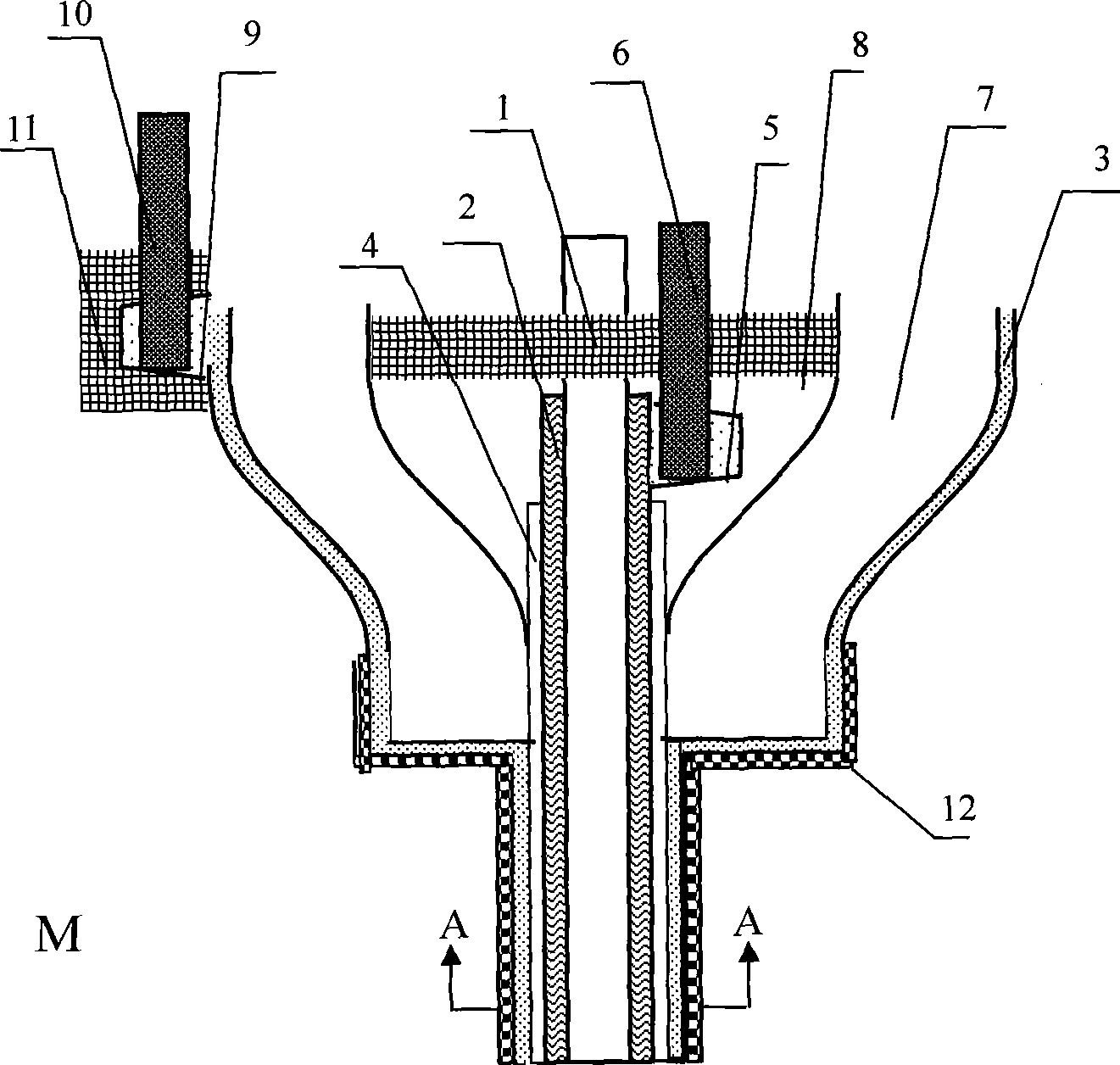

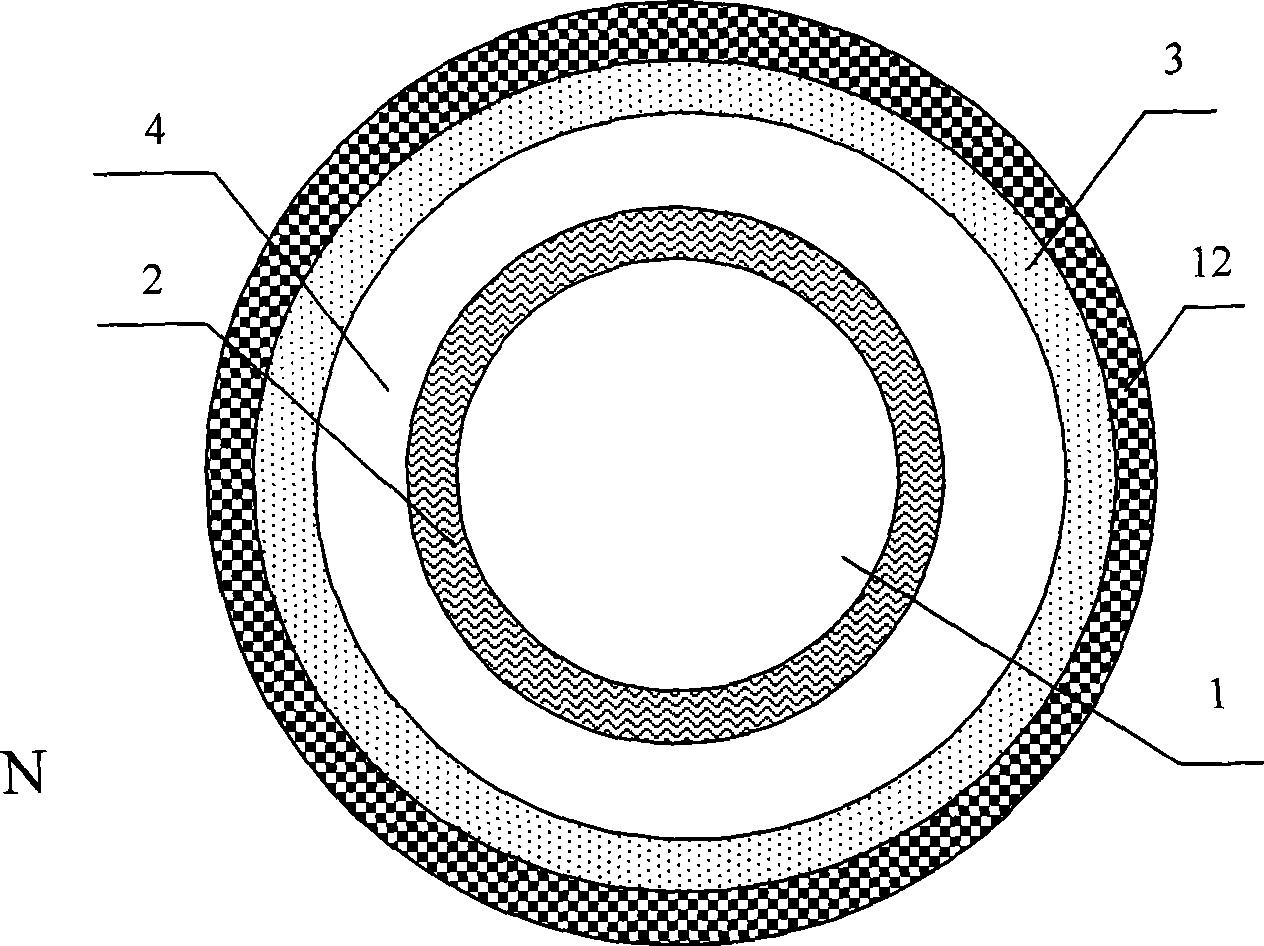

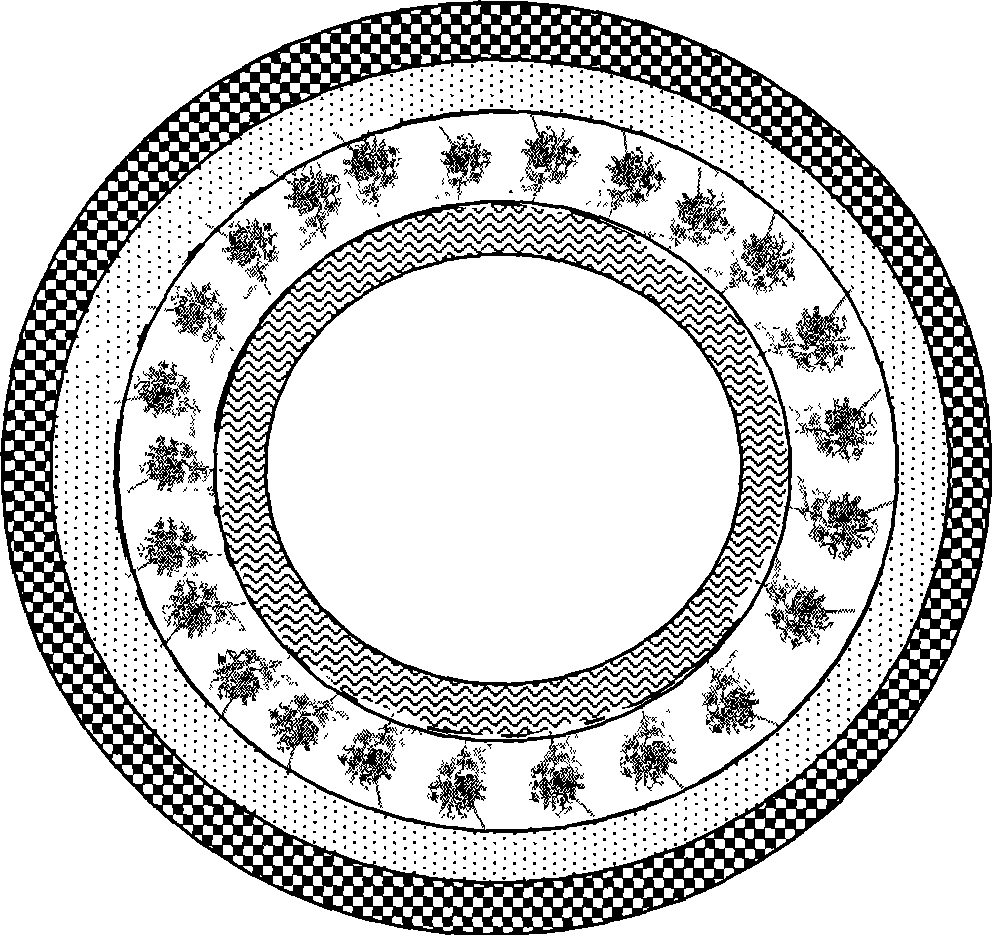

[0041] In this embodiment, glass fiber is selected as the insulating base material, gold is used as the inner ring conductor 2 and the outer ring conductor 3, and ethanol and double-distilled water are used for ultrasonic cleaning, the conductive adhesive 5 and 9 are silver conductive adhesive, and the inner and outer insulating layers 4 , 12 High molecular polymers formed by polymerization. The specific production method is as follows: first place the glass fiber in acetone to reflux for 10 hours, then use ethanol and double distilled water to ultrasonically clean it, and after it is completely dried, cut off a length of 3-4 cm as the insulating substrate 1, and evaporate a layer of it on its surface Gold with a thickness of about 20nm acts as the inner ring conductor 2, and is bonded to the end of the Φ0.1mm copper wire with silver conductive glue 5 to form the inner ring conductor wire 6. The gold-plated glass fiber is immersed in phenol and 2-allyl In the phenol solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com