Non-stress fixed installation structure of astronautic camera special-shaped glass prism

A special-shaped prism and installation structure technology, applied in the field of aerospace optical remote sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

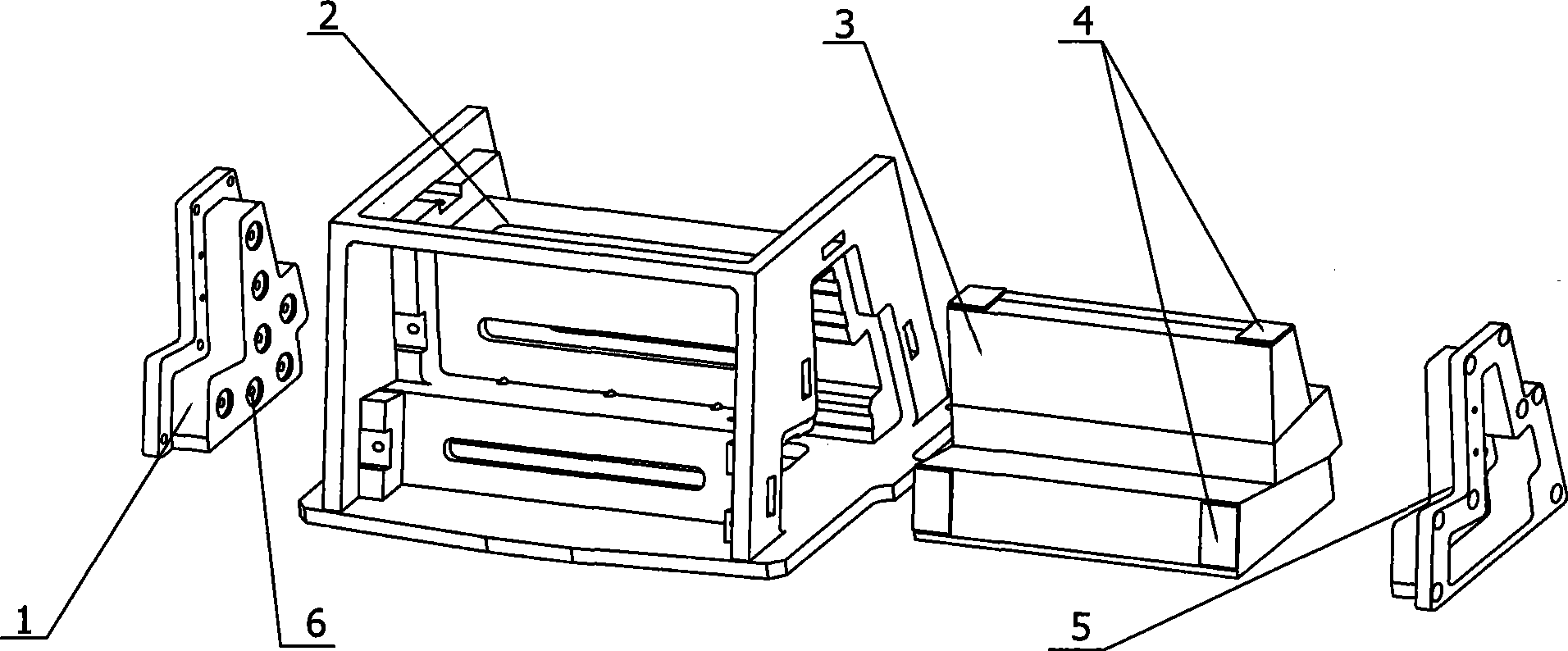

[0021] like figure 1 Shown, a kind of aerospace camera special-shaped prism stress-free fixed installation structure of the present invention comprises left block 1, special-shaped prism frame 2, special-shaped optical prism 3 and right stopper 5; Special-shaped optical prism 3 is installed in special-shaped prism frame 2 The left stopper 1 and the right stopper 5 respectively block the two sides of the special-shaped prism frame 2, and keep a certain gap with the special-shaped optical prism 3; 4; The left block 1 and the right block 5 are provided with step-shaped block glue injection holes 6 .

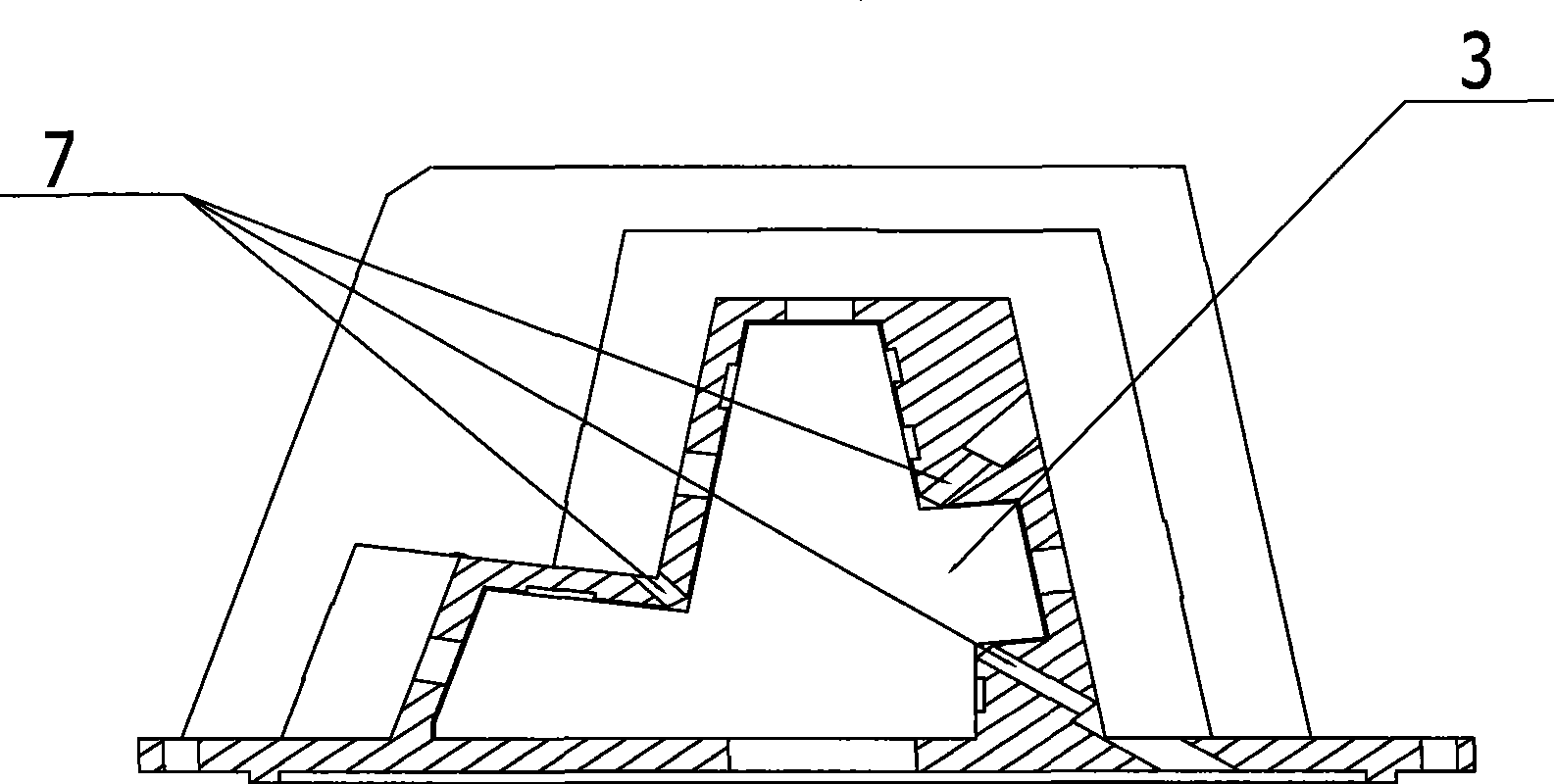

[0022] The special-shaped optical prism 3 in the present embodiment comprises three trapezoidal dichroic prisms that are glued together. On the bottom surface of the special-shaped prism frame 2, it is used as the incident surface of the prism light; the lower side of the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com