Feed gear of medical needle stand blade distributor

A technology of feeding device and needle holder, applied in mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems of unqualified product hygiene requirements, affecting the assembly process, low work efficiency, etc., to achieve smooth, fast and guaranteed transportation. Hygiene standards, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

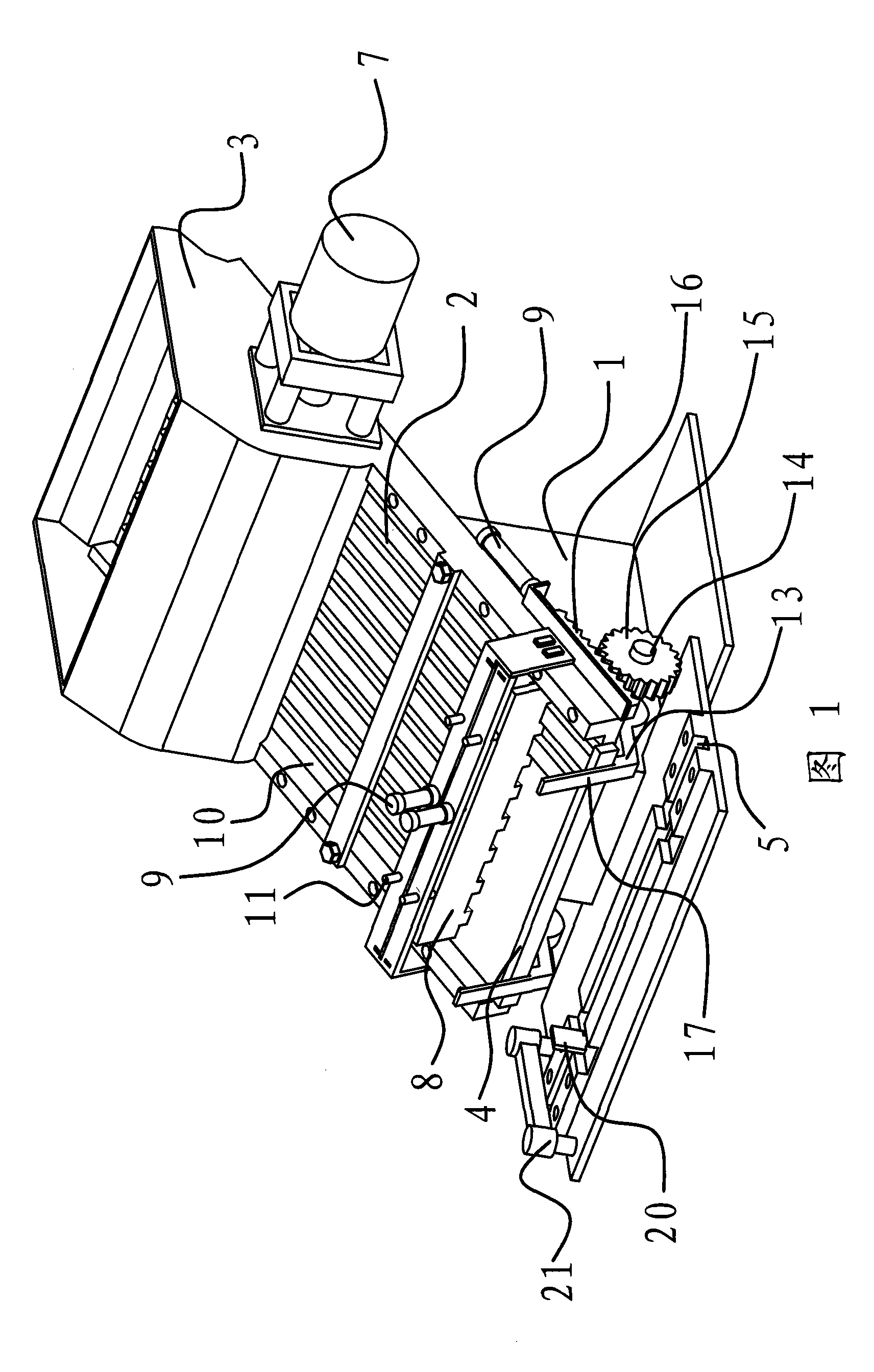

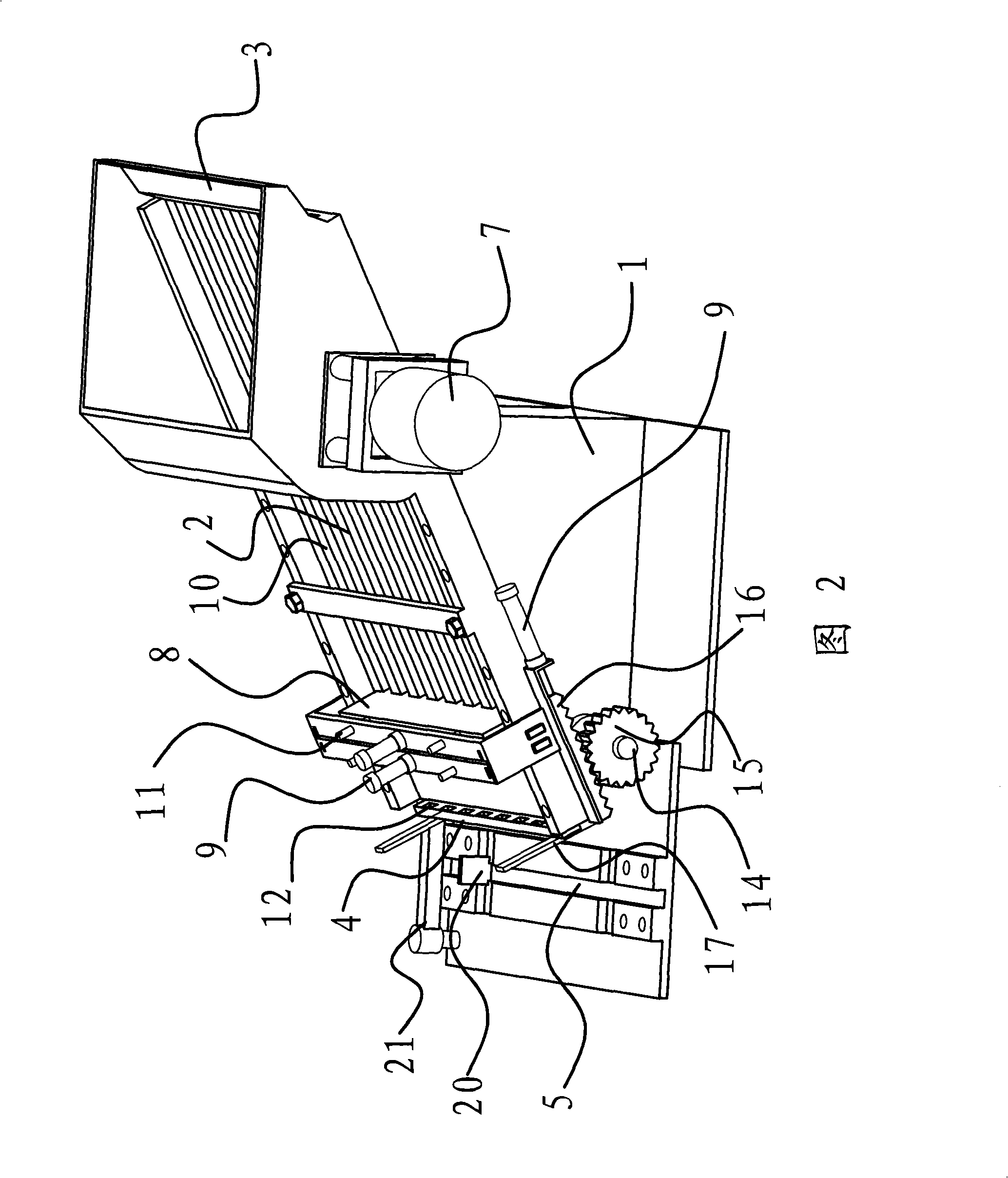

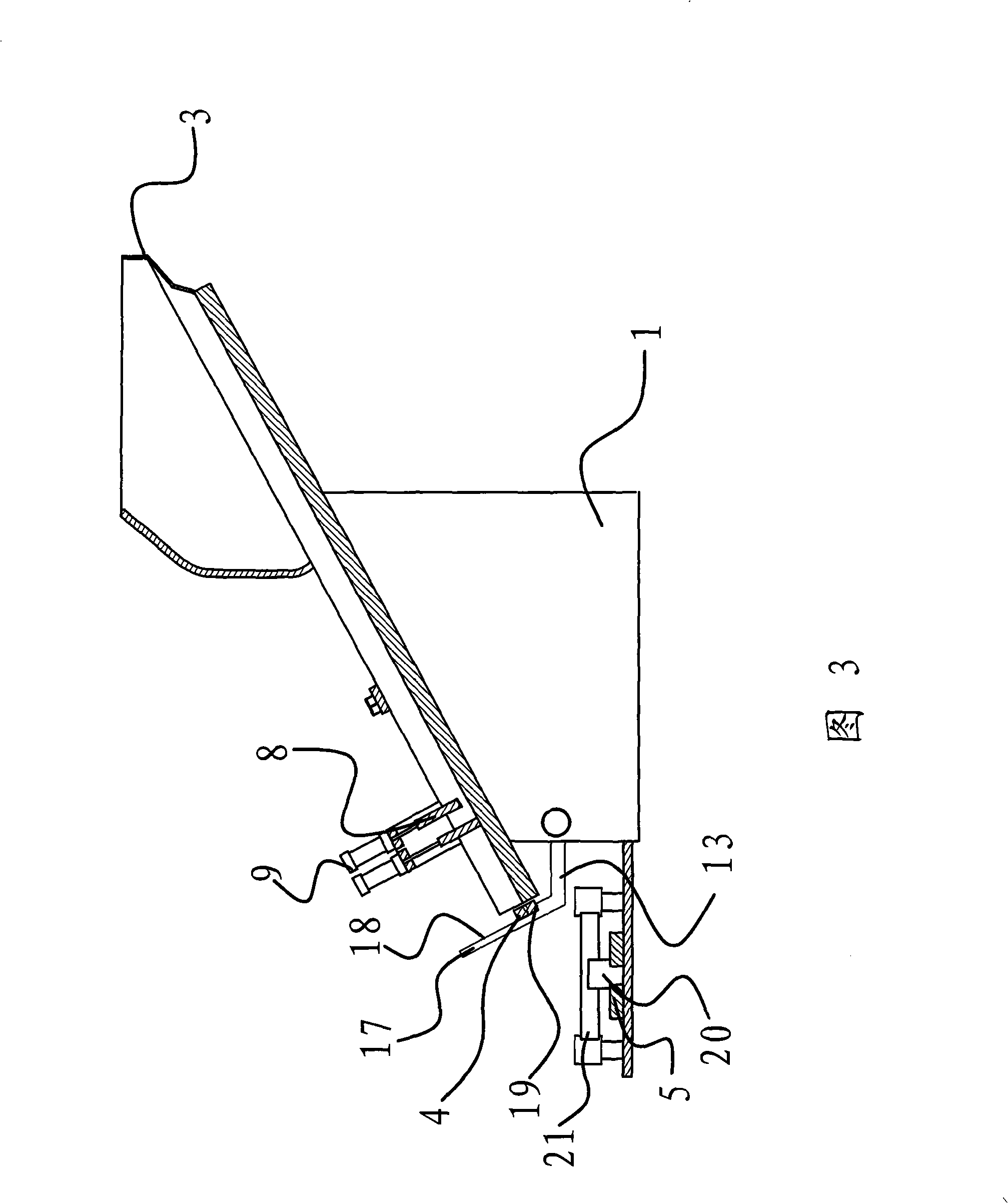

[0029] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the feeding device of the medical needle seat blade distributor includes a vibration platform 1, a scraper plate 2, a hopper 3, a blade clamp 4, and a feeding guide rail 5. The material distribution mechanism and the transfer mechanism can automatically send the needle seat blades 6 to the blade holder 4 one by one, and send the blade holder 4 equipped with the needle holder blades 6 to the next station through the feeding guide rail 5 .

[0030] Specifically, the scraper 2 is arranged on the vibrating platform 1 , and the scraper 2 is placed obliquely, so that the needle holder blade 6 can slide down and move into the blade holder 4 by virtue of gravity. A hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com