Preparation for preparing bio-fuel butanol

A fuel butanol and biological technology, applied in the field of biofuel butanol preparation, can solve problems such as not being able to meet social needs and endangering food security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

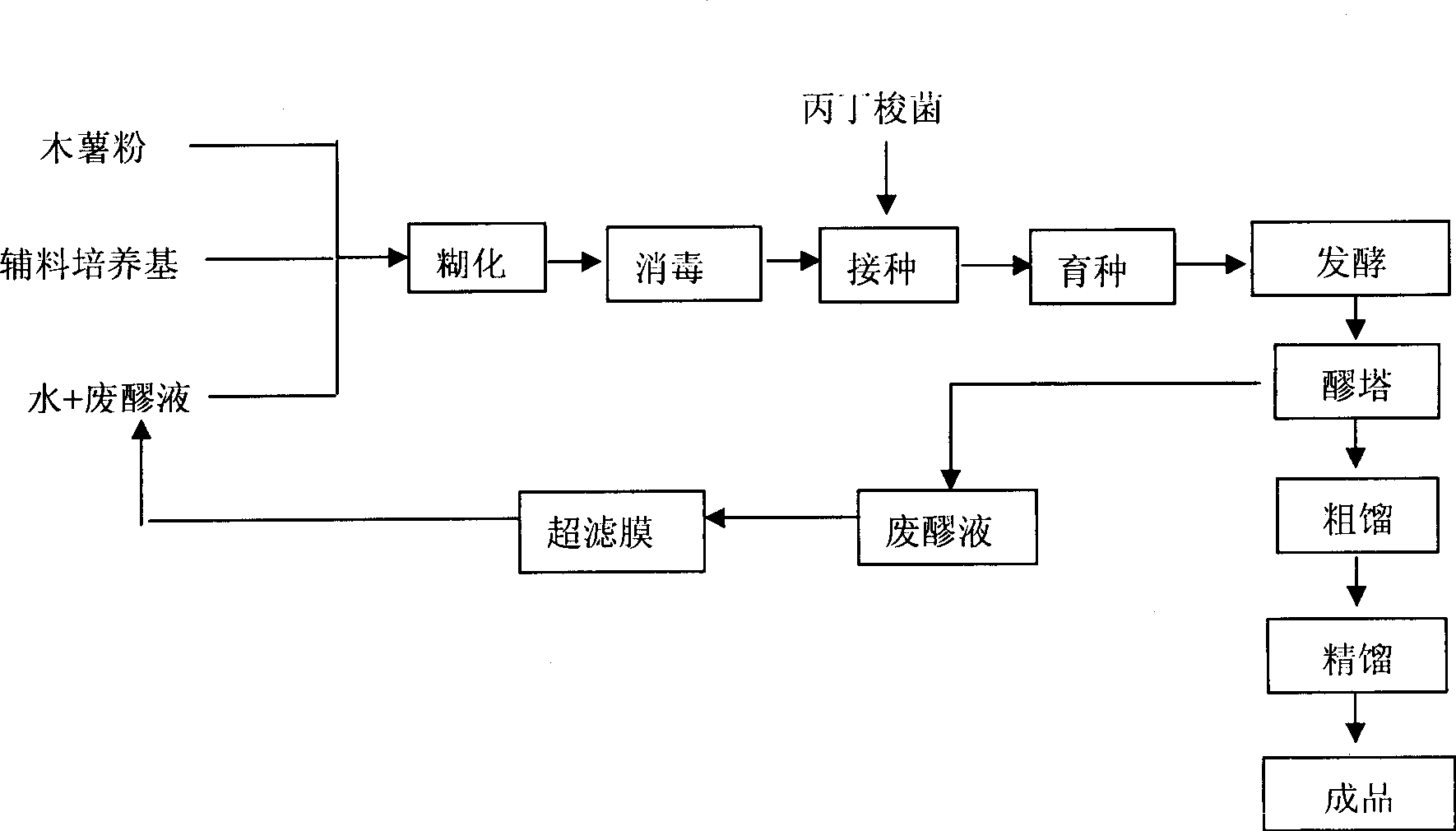

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of cassava flour

[0042] The raw material cassava is dedusted, impurity removed and purified, and then enters the pulverizer to form dry cassava flour.

[0043] 2. Gelatinization

[0044] (1) Weigh 960 grams, 1200 grams, 1440 grams, 1680 grams of cassava flour and auxiliary material medium respectively, wherein the auxiliary material medium is 9.6 grams, 12 grams, 14.4 grams, and 16.8 grams respectively. In this step, the supplementary culture medium accounts for 1% of the total amount.

[0045] The auxiliary medium has the following components: 50 grams of corn starch, 40 grams of protein, 9.7 grams of fat, 0.1 grams of lysine, vitamin B 1 0.05 g, B 2 0.05 grams;

[0046] (2) Add a certain amount of water and waste mash into the four gelatinization tanks, and heat.

[0047] (3) Take the slightly hot water in the gelatinization tank, and adjust the mixture into a lump-free paste. After the water in the tank boils, add it to the four tanks separate...

Embodiment 2

[0067] a, take by weighing 1680 grams of cassava flour and adjuvant culture medium, wherein 504 grams of adjuvant culture medium, add water and processed waste mash deployment and heat gelatinization, the concentration of gelatinization liquid is controlled at 10%;

[0068] In this step, the supplementary culture medium accounts for 30% of the total amount. The auxiliary medium has the following components: 60 grams of corn starch, 33.7 grams of protein, 5.7 grams of fat, 0.2 grams of lysine, vitamin B 1 0.001 g, B 2 0.001 g;

[0069] b. After the gelatinized liquid is sterilized and cooled, it is used as a culture medium and added to the seed tank;

[0070] c. After adding Clostridium acetobutylicum into the mother tank, inoculation, breeding and continuous fermentation are carried out; the fermentation temperature is 41°C. The fermentation period is controlled at 120h.

[0071] The products made in this embodiment are shown in Table 3 for details.

[0072] table 3

[0...

Embodiment 3

[0075] a, take by weighing 1680 grams of cassava flour and auxiliary material medium, wherein 840 grams of auxiliary material medium, add water and processed waste mash to prepare and then heat and gelatinize, and the concentration of the gelatinized liquid is controlled at 15%;

[0076] In this step, the supplementary culture medium accounts for 50% of the total amount. The auxiliary medium has the following components: 68 grams of cornstarch, 25 grams of protein, 6.79 grams of fat, 0.3 grams of lysine, vitamin B 1 0.05 g, B 2 0.05 grams, trace elements 0.01 grams.

[0077] b. After the gelatinized liquid is sterilized and cooled, it is used as a culture medium and added to the seed tank;

[0078] c. After adding Clostridium acetobutylicum into the mother tank, inoculation, breeding and continuous fermentation are carried out; the fermentation temperature is 36°C. The fermentation period is controlled at 96h.

[0079] d. The fermented liquid is separated by the mash tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com