Structure of amorphous alloy oil immersion type distribution transformer and manufacturing method thereof

A technology of distribution transformers and amorphous alloys, which is applied in the manufacture of inductors/transformers/magnets, transformers, fixed transformers, etc., can solve problems affecting the cost performance of amorphous distribution transformers, restrict the promotion and application of amorphous distribution transformers, and achieve material costs Low, constant and good magnetic properties, solid and compact body structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

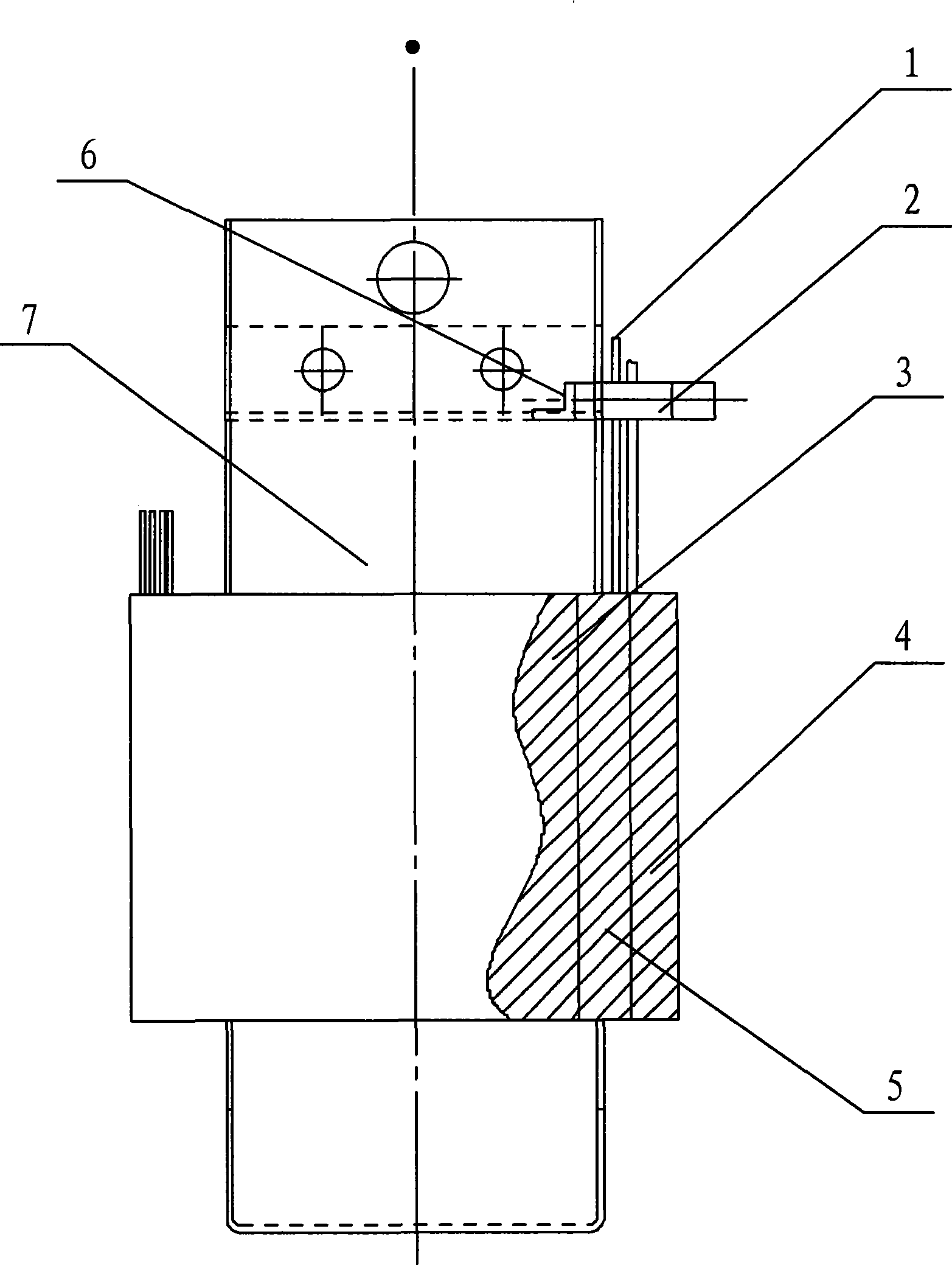

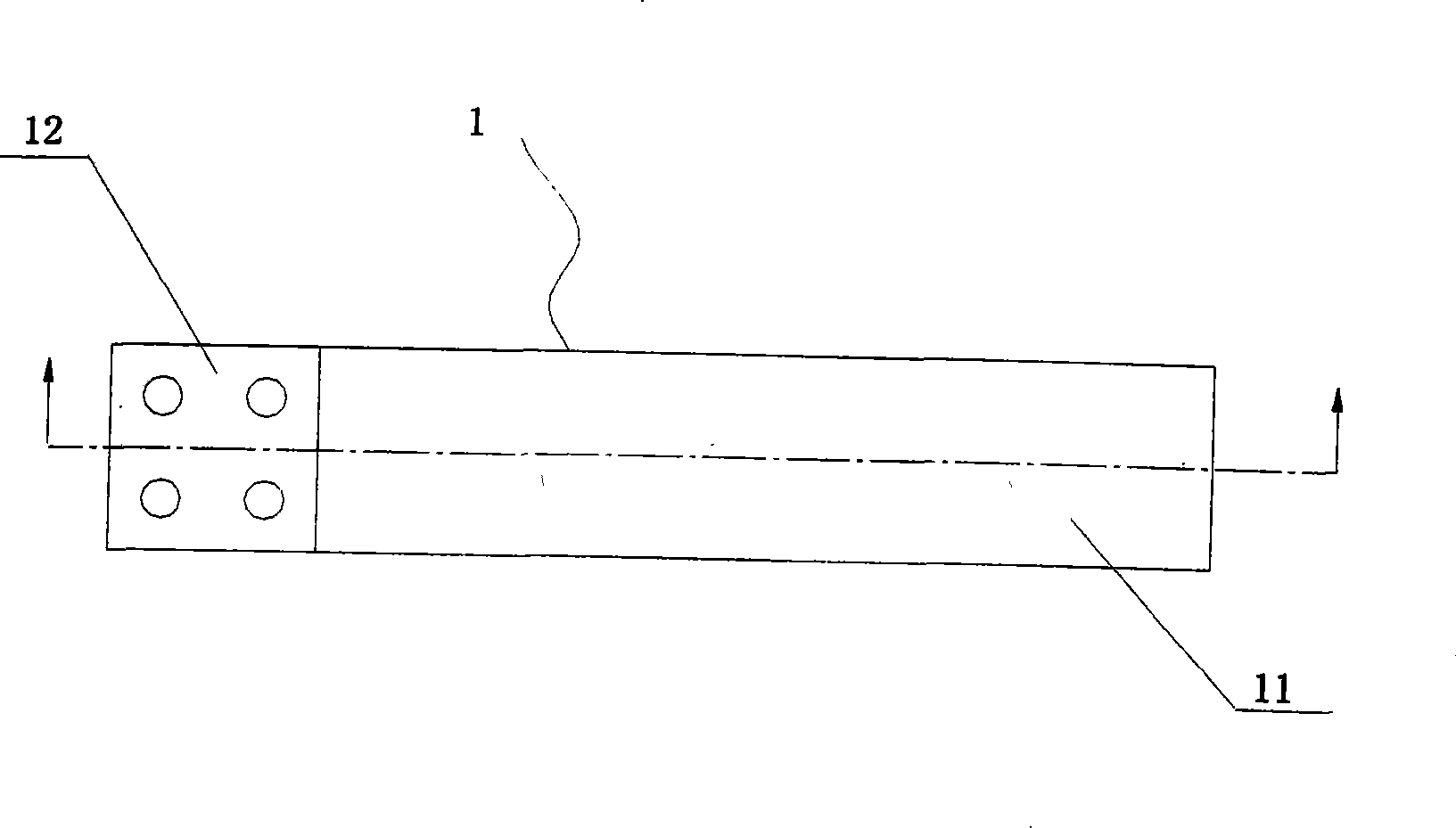

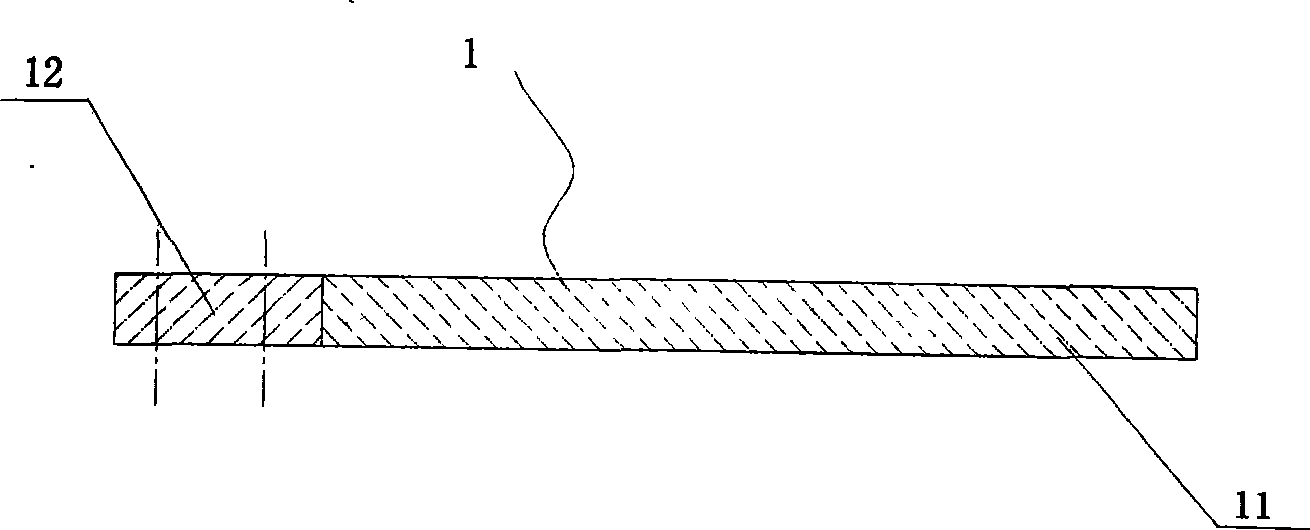

[0016] see figure 1 , the structure of the amorphous alloy oil-immersed distribution transformer of the present invention shown in the figure, comprises three-phase amorphous alloy iron core 7, high and low voltage coil 4,5, upper and lower clip 6, end clip (in the figure not shown), an insulating frame 3 and a conductive row composed of several aluminum-copper transition joints 1 . in,

[0017] The amorphous alloy core 7 is a four-frame five-column or three-frame three-column structure with a rectangular cross-section. The core 7 can be composed of one row or two rows of amorphous alloy cores 7 stacked side by side; the high and low voltage coils 4 and 5 are set on the core column.

[0018] The upper and lower clips 6 are arranged at the upper and lower ends of the high and low voltage coils 4 and 5 respectively; the end clips are arranged at the outer ends of the high voltage coils 5 on both sides.

[0019] The insulating frame 3 is a rectangular cylinder whose inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com